Who offers rental equipment? Have not seen this option around.

This is a solid idea, and I’m orienting toward this.

Fixed, thank you for the feedback. yes, F.

Ok this is super helpful.

So I follow the linked articles guide, set up a metal container, then some buckets for removing the flowers, then get the eth and material to -70 w dry ice, extract while mixing w a paint mixer for 90s, and pull most of the material in that short time, is that right?

Following his article, making a 2nd pass to get another boost to yeilds ( 50% of what i got in the first pass likely compared to the first pass )

Is that what you mean by done correctly?

Good to know. So can I put to rest my concerns about it getting too hot through the current distillation approach? With the InstaPot hitting 260F at minimum setting, and then as you said, the material heating well past that in all likelihood?

And if thats not a concern, what exactly is the point of failure of the current system in your perspective? Why wont it work?

I mean, if I fail to chill the alcohol vapors enough to reclaim the alcohol, that would be a reasonable explanation of course.

See It washes the cannabis and then it washes the cannabis some more

for approximation on “done right” (imo) for EtOH extraction.

Works with other solvents too. ethanol has its advantages, but there are definitely more than a couple of ways to skin this cat.

If this 100lb is one and done for y’all, you are looking at an awful lot of work for essentially zero payback. You need to buy it solved or just walk away from it. If the learning experience will serve you, because you actually have to do it again? It might be worth your while digging in and figuring it out.

Unless you’re planning on distillation of your cannabinoids, getting to market viable concentrates with ethanol will simply not work in the SF Bay Area, or anywhere on the west coast imo. that’s a whole other set of tools and learning.

Hash rosin on the other hand…especially if you already have half the gear

Except that quality and yield are very input dependent

It cannot hit 260F with ethanol in there. If it tries, by being pressurized, the pressure will exceed its design rating and release (which may well be the issue you’re having).

if you haven’t already looked into: Bucket Tek (Cold Ethanol Extraction on a Budget)

then Reflux Still For Small-Scale ETOH Reproofing

Show me…

And go see Purging ethanol with hot plate

That was the point where my kitchen countertop extraction experience ended. I tried decarbing after extraction instead of before, and it turned to mud. Lacking spd, decarbing the flower first is a much better idea.

OP could just make bubble hash for next to zero additional cost, cut losses/lick wounds and move on. A fundamental principle of investing is to not keep throwing good money into a bad investment.

Have you considered turning it into something similar to moroccan hash?

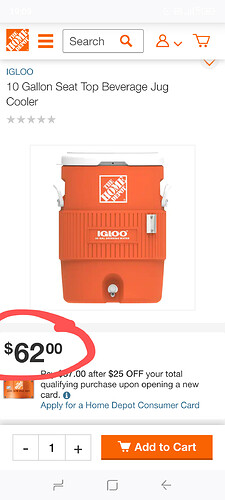

You could get 3 of these

and do a few runs but even if you were to buy 10 of them you’d still be hitting a thousand dollars. It’s gonna run you money for pure etoh that’s not heptane denatured as well. 200 proof is usually cheaper than 190 but 190 is what you want.

Ballpark range:

You’re hitting another 600-1000 for solvent

Your rotovap is gonna cost you from 800-2.3k

Your vacuum purging device is gonna cost you 800-1.2k

You’re better off getting some one else to run it for you and cutting your losses trying it yourself if it’s only one load of that 100lbs.

What equipment do you already have?

my advice, keif it and sell the keif. You can do this rather simply with a very low budget.

To keif the material I would suggest you:

-

Fill a five gallon bucket a quarter full or less with the plant material.

-

To the bucket add several large scoops or crushed dry ice or pelletized dry ice.

-

Pull a bubble bag 75 um or 120um over the top of the bucket until the mesh is even with the buckets top lip.

-

gently swirl the material inside the bucket for a minute or two until the material is good and cold.

-

Turn the bucket upside down over a clean surface such as a table or a bin.

-

Shake and swirl the upside down bucket like a big salt shaker. Keif will fall through the screen. It can be collected by scraping it up into a pile with a card or paper.

If you are too rough on the material you can get excess plant material, you might want to try a few UM sizes of bags to dial in your particular material.

From here you could go two routes, sell the keif or process it yourself.

If you are going to distillate you could extract the keif with ETOH , winterize , then go to heptane and strip the color through a bentonite column.

This is possible to do with small batches of solvent, but it is going to be a pain to distill solvent over and over again to process all of that material. Not to mention the cost of the equipment needed, and that isn’t even getting into making distilling cannabinoids.

Imo best solution keif it and sell it.

Here is a video I found demonstrating the process.

You could look into having a stainless 316 sanitary grade extraction keg made custom for you that could be your 500L washer which you’d use about 400L of that room leaving good head space and then from there you could go into a filter system which then leads to your evaporation unit which would be constantly distilling.

This could run you under 8k if you do it right.

Anyone care to chime in?

You could also mod your roto with a keg for recovery

Thank you for this.

Re: 10 gal brew pots, looked into this, found several cheap options on craigslist. perfect sizing for 10lb runs. Dig it. Added to the plan.

Re: panda spinner. I liked this for getting the last of the alcohol out after the rinse. Intuitive, $200. Added to the plan.

Re: diaphragm pump. Ummm… how does this fit into this system? And how would you recommend evaping? Lots of super small scale videos on youtube have folks just wash then air dry, so I imagined a non issue with using the pressure cooker instant pot style still to recapture the alcohol but It sounds like the rototap is essential. Its not a cheap part of the puzzle, likely 1k min for a used unit.

What does the d pump go to and from in your mind? Are you picturing a rototap or is there a cheaper DIY alternative that wont burn / ruin the product?

Most Dpumps are in the 800 - 1000 range, save for this one, is this what your meaning:

VEVOR Air-Operated Diaphragm Pump Efficient Fluid Transfer ?

A 20 Ton Dulytek Rosin Press Setup including accessories

A Centurion Pro Tabletop Pro Wet & Dry Automated Bud Trimming Machine with wet and dry tumbers, do not have the additional $700 retail keif tumber addition. It does some separation of keif from what is trimmed.

Most of the items described for the ethanol extract except a couple of most expensive ones:

I have

- a single Buchner funnel setup with papers and media

- the alcohol

- a 3.5 CFM vacuum pump

But instead of a rototap, I have a homemade still exactly like the video I linked above with the DIY copper coil going to an insta pot with a lowest temp setting of 260 degrees if I want pressurization. It only works as a still pressurized, pushes alcohol vapor through a copper coil in a 5 gal ice and water bucket, and recaptures alcohol, only worked at 50% recapture so far.

Small shop space in a licensed commercial setting with only a double door and window facing outside, and I have the gear to add professional ventilation ( high cfm fan etc ), but have not yet paid to have the vent added.

Like was said before if you aren’t going to do this again you might be better off just letting someone process it for 5k. You’ll end up spending that much on equipment to get a good distillate and with the learning curve might not get a return on your first 100 lbs at all unless you take it to edibles because your distillate might not come out very good or to get it good you might have to take pretty reduced yields.

Just get some guarantee the product they’ll produce is going to be able to be used in carts later if that’s your goal. I mean like a guarantee on color or potency.

Just whatever you are going to make, be sure you’ll have a market for it. Stiff out here on the west.

Some issues from someone who tried all this years ago. Keeping your solvent and material cold enough during spinning and during filtration. Vacuum assisted Buchner filtration through deep media is very time consuming and needs to be done in stages especially after you’ve winterized. Having too much ethanol in your solution can prevent effective winterization. Recovering ethanol with only heat and condensing strength takes too long at temperatures that are too high and darkens your oil, usually to a deep red. Plus a bunch I don’t remember… oh yeah, ![]() walk… and that’s all just to get the crude eho.

walk… and that’s all just to get the crude eho.

The thing to keep in mind too is you say 10%, that’s the crude… so 10lbs of say 50-70% extract. Then it gets distilled in an spd… now you’ve got 70-80% extract, but you’ve only got like 6-8lbs left… then take that a step further to get to 90% THC and maybe you’re down to 4-6lbs. So maybe 2-3L. I could have this part wrong though, but this understanding is why I don’t like distillation.

Wow, didn’t think about this, I had not imagined modding a keg to be recovery nor the possibility of continuous distillation.

Does the swapping of a rototap for a 260F minimum pressurized ( insta pot ) still feeding into a DIY alcohol recovery via stilling sound like it would not work as a substitute for the roto?

Several folks including @cyclopath have stated this would be a mistake but hoping to discern why.

The concept of continuous recovery sounds like an advantage i would lose out of in this context.

No sign of a “distillation” plan that I can see.

Only solvent recovery and a wish to achieve EHO dabbables or vape pens.

Did I miss something?

I agree that actual cannabinoid distillation should be part of the plan if carts are the goal in California.

Like you, I don’t see how distillate can be achieved by OP given the budget constraints. I wouldn’t call the task impossible by any stretch, but the skills required to nail this in one generally take years to acquire.

Your the 2nd person to speak to keif before extracting and I looked into this more, specifically DIY options for this which would automate it. Saw the video and it just looked labor intensive.

Then I found this video

"Simplest way to make keif and canadian rock hash bricks w pressed kief "

And from that was able to discern an example for automation of parts of the process.

And the cheapest but out of stock auto kiefer machine i had found was $300 and operated by simply a vibratory motor ( 30 bucks ) and some springs. I have been chewing through how to recreate that since they are out of stock and from each of these videos I see a way to create an automated kiefing machine for less than $100.

5 Gallon bucket

with bucket mount -

https://www.amazon.com/gp/product/B08M3NH4NJ/

connected to vibratory motor strapped to the side

https://www.amazon.com/gp/product/B09FLLFBFG

5lb of flower and dry ice, vibrate for 3 m

pour into bubble bags already inside of each other

return to the machine face up

vibrate another 5m

pour each bag and the bucket into separation buckets for each tightness

This then can be

- rosin pressed for higher-end clearer rosin

- pressed into Canadian rock hash as in the above video ( I already have that press )

- and the greener output of the 220 can be eth dissolved and thus turned into filtered eth extract

My only working assumption is that I would need to hang the bucket… hope this helps others.

Really?

tried to hand that ![]() to you that more than once, along with the link to the $1k Rotovap….

to you that more than once, along with the link to the $1k Rotovap….

The second time I pulled in a picture too…

Yeah. Lot to take in. Which is why I offered to assist. Your budget doesn’t have room is an acceptable answer…But you’re gonna need to read