Are you stirring or agitating at all?

But what does your vacuum gauge say? You need a vac gauge to adequately know if you have any vacuum leaks otherwise your running blind.

Meh. “Starter” size for most, but not all.

You’ve got zero to base that on…

Digital vac gauge or you’re guessing.

Yes, you can perform the trick without one. But it ain’t no way to learn it.

Damn straight. Ideally you’d want 600ml-1l in there.

If you are only willing to throw 100ml of crude at the problem, why do you have a 2L setup?

Tell us about the 100ml you started with. We had one user around here load ethanol tincture and expect distillate.

New mantle too?

Get a gauge first imo.

Not ideal, but should get the job done on a tight 2l setup.

@Roguelab probably has better data than most on just how far one can stray from ideal when performing this trick with what ya go lying around.

I assume that temp probe is in the puddle, so “mantle” temp is actually the temp of the liquid in your boiling flask.

Having head temp as well is a huge help when learning/trouble-shooting. in production it is often the primary data point used to guide operator.

How about the rest of the setup…

Cold trap?

Plumbing all the way back to the pump.

We’ve had to point out “dude, you can’t suck through a collapsed vac hose!”

Only caught that because “pictures or it didn’t happen”.

How much reading have you done before signing up?

Because this topic is has been thoroughly explored…

while you could certainly throw more suck at the problem, or more buck on glassware and a smaller mantle, you’d be better served by a data driven approach: head temp and digital vac gauge.

Yes stirring

Is there a stopper in the head?

I dont want to buy vac gauage its quite expensive here but cant we go without vac gauge? If the pump is running fine. Joints are sealed with vac grease. So how would it’ll be leaking all my silicone hoses are tight and no air leak from any of one

Yes head is closed from top bcz i dont wanna read out head temps.

After turning my system off. I realized my crude was so less and my vacuum pump isn’t big enough for 2l setup and for vapors which have to travel all the way from down which is 100g crude and there is much rmpty space up on bf. And i got one drip after 1 minute and then the reaction stopped for minutes then started out a drop after 2-3 minutes.

Yeah i dont have a vac gauage.

And silicone hoses are cleaned.

I’ve seen your post bro where you are running 250ml setup with robinair and i just read recently after my failure in last run. I think that my pump and robinair are both similar in functionality. And how’ll 250ml setup run if i apply on this pump and my crude will be max 90-100 g. I just want to run spd for my self. I am distyy lover and just wanna distill it for personal use.

There are too many unknown variables for anyone to give you a definite one answer of what it is that’s wrong with your setup. I mean I don’t turn on or pay attention to a vacuum gauge in my setup almost at all anymore. I make my own crude and I follow pretty much the same procedure time and time again so just by looking at temperatures, collors consistencies, rates of drip and vapor through the head I pretty much know exactly what’s going on with my processes and what is coming over at that time… But it didn’t start off that way. At first you need to have a good understanding of what it is you’re looking at with all applicable measurements so you understand what everything is otherwise you’re just pissing in the wind. Having said all of that if you are at 237°c in your boiling flask, the very first things I would think are of concern is that no matter what your vacuum pump is supposedly rated at your system is not in anywhere near sufficient vacuum pressure for whatever reason and there could be multiple reasons. Next concern would be that you are using an incorrect distillation head. Next after that which at the same time could have been the very first thing you should check is what exactly you are trying to distill? I mean are you sure it’s actual Target material crude oil?

If you’d like me to get on video with you and walk you through step by step to make sure you are successful send me a DM with signal app number I can get you on.

You’ll need a vac gauge. Blank off pump and verify it gets at or below 50 micron. After that try connecting to the system dry. Verify that reaches at or below 50 micron.

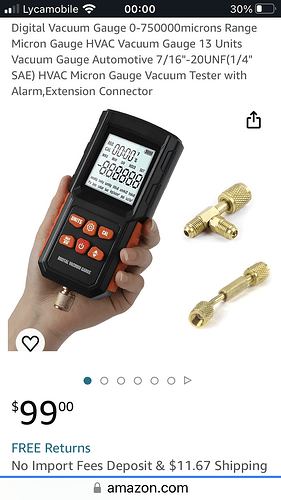

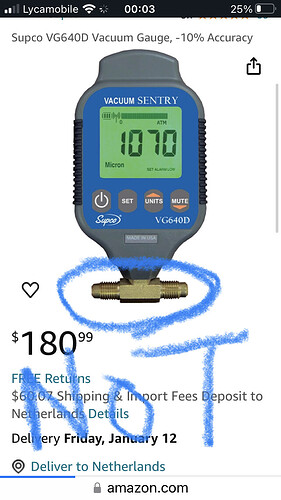

Vacuum gauges are not so expensive

Simple hvac gauges work

And a simple copper soldering T with a s-flare coupling fits most hoses as your

Connection point

Get a gauge that fits on a T

nOT a version treu Wich the vapors pass

I think most of them are JIC, easy enough to adapt to a kf fitting

Oefff ya got balls

I do not need temperature readings

But without vacuum readings I am lost

Probably because I am very anal about good vacuum But defenatly for a starter work with a gauge

I swear I have not looked at a vacuum gauge in over a year. I know my system well enough to look at the temperatures, look at the color, look at consistency and obviously I already know which part of the process I’m supposed to be at and it seems to work just fine for me. Obviously if I see a temperature color or consistency I’m not expecting at that particular time is it cause for me to start paying much closer attention and try to troubleshoot from that point on.

This is results of my last run last week and keep in mind on that specific run my solvent with product desolved in it started off as dark black because starting material was complete and utter trash that was swept off the floor, I did not use any expensive filter media in fact I did not use any filter media made for the industry and yet with going with the methods I described above I got this results-

Im with you @Roguelab my vacuum temps are my guide to the rest of my settings.

I am picky I wont run until I have achieved the vacuum I like. Which is usually chasing vacuum leaks and sets the rest of your run up for success. Be a vacuum stickler its only going to make yalls life easier!

Im using wiped films these days but can remember all the times, ive had to tear my short path down and reassemble chasing vacuum leaks haha it can drive a man mad after 3-4 times

My solution!