Hey everyone! I recently started messing around with SPD of ethanol extract and oh boy was I overconfident in my chemistry knowledge. I had a little explosion due to high temp and I collected something but not sure if we got any THC in it. Any tips/pointers/suggestions are more than welcome. I explain the experiment parameters and equipment in detail under this paragraph. Thanks in advance future4200 community! ![]()

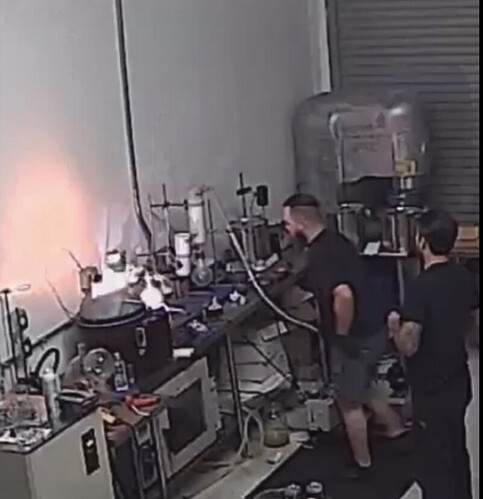

(Pictured here is our 2L setup, its the same setup except it has a 2L boiling flask)

Extraction

-Flower mixed with ethanol in digester

-Flower filtered out of solution

-Put crude in -86 freezer overnight

-Filter the crude extract

-Decarb/Solvent recovery

Equipment:

-5L boiling flask

-2XZ-2 stage rotary vane vacuum pump

-VMV-1 digital vacuum gauge

What happened during SPD:

-Used vacuum pump, over boiled so we switched to a weaker diaphragm pump

-Started up the heating mantle at 60 (all temps celsius) when it reached 50 increase to 140. -Once it reached 130, increase to 220.

-Got bright orange head fraction around 150ish

-Started getting darker orange/amber fraction around 180

-After that, clear colourless liquid around the 200s

-Head temp after starts dropping to 50- 60 from around 100

-Decide to increase temp to 240 since nothing more was happening

-We got impatient, bumped to 300 from 240

-Thick white cloud of smoke appeared at cold trap

-Pressure build up at rbf - explosion

Identified problems:

-Solution over boiling with vacuum

-No way to control/release vacuum if needed

-Not enough vacuum

-No acetone/iso at cold trap

-No insulation for rbf

-Very little/no stirring

-No heated water in condenser

-(Obviously) too high of a temp change

Thing to change for next run:

-Buy insulation rope, and better stir bar

-Buy a water heater?

-Be more patient

-Change positioning of vacuum gauge to be beside the vacuum pump instead of in the middle of setup