Item:SweetLeaf Systems 6” WFE

Location: North Hills, CA (San Fernando Valley, Los Angeles, Southern California)

These machines are just hitting the market, manufactured in the San Fernando Valley, CA. I have been lucky enough to be one of the first few people running R&D on them. My name is Ryan, I am a lab tech at Kush Alley in North Hills, CA and I am employed by the designer/manufacturer of these systems. There are several machine skeletons ready to be brought to life if anyone in Southern California (or other areas) is looking at purchasing a new system and interested in giving these new SweetLeafs a whirl, I can assure you they will not disappoint.

SweetLeaf comes with the application of wipers, a 6L feed reservoir, hard lined circulating baths to the feed tank and evaporator column as well as the jacketed residue and distillate collection. The cold trap comes equipped for use with liquid N2O and the internal condenser is finger shaped, instead of coiled. They also feature ball valves directly above the receiving flasks to make flipping flasks and passes a breeze without having to break vacuum. Several other components have been modified to provide peak performance with ease of operation and maintenance (tri-clamp breakdown of discharge lines, tri-clamp ferrofluid rotary feedthrough). These systems come turnkey with a stacked list of applicable items,

- Julabo heating circulator baths all around

- Heidolph Hei-TORQUE 200 drive motor

- Edwards 10iC dry scroll pump

- Edwards nEXT 240 molecular turbo pump

- Edwards vacuum gauges and display

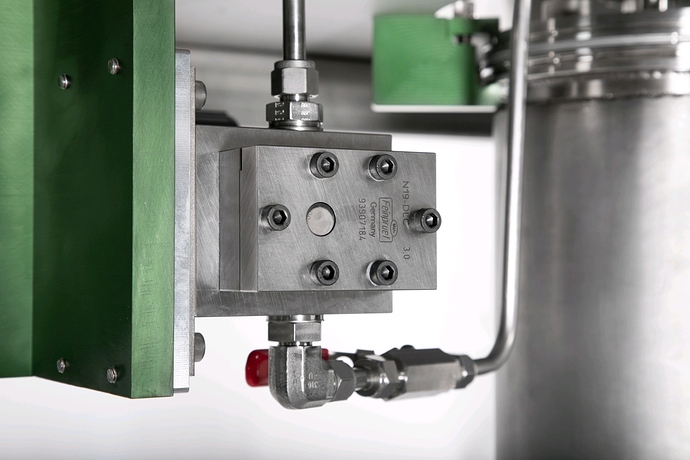

- Mahr Feinpruef Germany gear pumps

- Chemglass receiving flasks

- Swagelok bleed off valves

I have been running two of these machines (the prototype and the first edition) over the past couple of months and I gotta say, WOW! Not only do these machines look beautiful, they perform just as well. Easily 3-5L/hr output (of proper distillate) and 4-6L/hr throughput. Definitely capable of running faster while stripping volatiles or running a polish. I have yet to encounter any vacuum leaks, or machine malfunctions to date and we run these machines hard, (24hrs a day/5 days a week) running a terpene strip, and two passes of thc distillate. Always pulling 99+% cannabinoids and usually mid to high 90s thc potency. Say hello to SweetLeaf Systems!

Upon purchase these machines will come backed with 1 year of quality technical service and support, a 1 year warranty on any malfunctioning parts due to manufacturer flaw (Operator error not covered), a 1 day installation and training session, and an SOP.

These systems are designed, manufactured, and supported by master growers and engineers who are from the community and have been in the industry for decades, all with the same passion and love for this sweet leaf.

Price: Please contact directly for a quote.