Hey guys, inherited a lab recently with an ETS MEP system. For the most part, the system has been great but recently our dual haskel pumps stopped working due to an ice clog in our recovery coils. I cooled down the system, cleared the clog (pumps proceeded to work fine when doing a small butane distillation test), and figured that the problem was simply that the sieve beads had been overused and needed to be changed. Upon opening the back columns on the ETS that I assumed housed my beads, I discovered that there were none in there.

I figured ok, ill use new butane and add beads to these things and my problem is solved.

I dig into the ETS manual and they say the back columns are for overflow protection for the pumps. Basically if you send too much butane through your recovery vessel, itll run through these heated columns and vaporize before hitting the pump.

The way these are configured is stumping me. Do I need to run a separate sieve after these overflow protection vessels in order to dry my solvent? The overflow vessels are the only inbetween my pump and my recovery vessel. They have a dip tube going to the bottom in order to force any unwanted overflow to hit the jacketed/ heated walls.

I dont think these are meant to have beads in them. The diptube prevents me from running a filter gasket on the top part, which means there is nothing stopping my pump or any other vacuums or pressures from sending my beads through my valves and lines.

Does anybody else here run the ETS MEP? Do you guys use a sieve? do you just run a separate sieve before or after the overflow vessels?

Any help on how to integrate sieve beads into the ETS would be incredible.

Thanks guys,

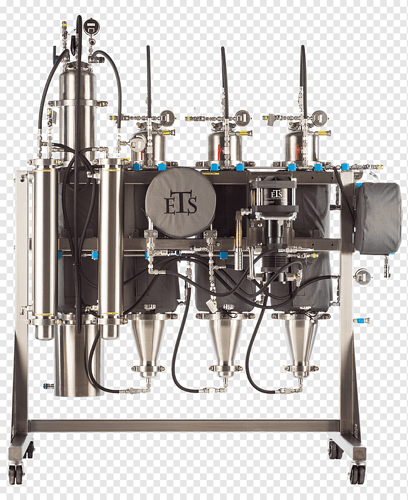

photo is for reference, we run the double pump system but it is hard to make out the details so I included a photo of the back of the single pump as well.

Yes these are meant to have Mol sieves and I used to pack them in socks and put them in the back chamber between the honeypot/recovery and the haskell pumps.

ty, socks were my only thought of how that would be possible as well. Otherwise nothing preventing the beads from flying everywhere throughout the system.

Good luck

I’d pack it and do a few dry runs til your solvent is dry then repack again with new/regen sieves

I thought you were just supposed to put the sieve in the cups on bottom of each expansion column??

I thought about that as well, but I cant see how that would actually dry much butane as it doesnt force the majority of it to pass through the beads. Also, most systems want a decent amount of beads and those cups are quite small.

Maybe I had it wrong but I thought the cup was for a quick clean in the case of overflow. You know like a removable resin catch.

Well from what I understand those two columns are not meant to take on much solvent. Those are to by pass for recovery from top of material columns no?

I used that model for 3 years and never had a clog on the recovery coils. I only ever used sieve in the cups, if I remember correctly I also had a convo with a ets tech who told me the cups was good for the sieve.how would you put a sock if the dip tube goes all the way down to the base of the screen gasket covering the beads?

I’ve had ice crystal clogs in the chilling coil before. And from cured bio not fresh fro. Had to thaw the system to get solvent movement and you could see shimmering little shards in the tank (we had the upgraded solvent tank).

I think we all agree that you need sieves somewhere. You can pack the sock along the diptube, I made it work and I bet you can too.

Man, what a weird design for sieve’s. I would have 100% said they were resin traps. Never heard of a sieve having a dip tube.

In theory you could form the sock around the diptube, which would allow all the gaseous butane during recovery to pass through the beads while also containing them as a normal sieve with two filter gaskets would.

Can you elaborate on what you mean by bypassing from the top of the material columns? Ive noticed that at the end of the manifold at the top of the material columns there is a valve connecting to the expansion columns but I figured that was for some sort of weird emergency/ if you somehow managed to overfill the material columns. I figure opening it would just pour all my butane from my input coil right into the expansion column and I cant see why I would need to do that.

I spent about a year running on the same model as a tech but didn’t have to deal with any of the maintenance.

@Pupparoo yes once in a while you’d get some resin in there. Our unit was installed by ets tech and he filled up the beads in the cups as well since I remember the first time I went to change the sieves I found the empty tube with the dip tube and the cups had the sieve the tech put inside. But yeah definitely need sieve’s

I would think that would be for recovering the gas out of your material columns? On my system I have a t at the bottom of my sieve that has a line running from top of material column.

Only thing I can think of. Idk what the fuck else you would use that for.

Its not connected to the columns directly , its connected to the filling manifold. The manifold pretty much stays filled with butane in between runs so opening that wouldnt even clear gas from a material column until the injection coil and manifold had emptied of liquid butane.

That’s a by pass, to relieve excess pressure from columns and to recover from material columns while recovering from collection pot.

Ahh. Makes sense.

I was taught to try and avoid letting liquid solvents into the expansion columns. I believe those were meant for gas before going into chilled coils and re condensed back in solvent tank.

Gotcha, I appreciate the help and insight from everybody by the way. The ETS is a brilliant system but the quick connects and small ports along with random stuff like this end up driving me crazy. The loud haskel pumps dont help either.

Totally, I recommend removing all quick connects (except those on material column jackets) and hardline. You’ll get no leaks or busted quick connects, especially running cold solvent through them for a while shrinks the gasket inside qc and causes leaks.