Use less water and/or more sugar in your formula and the coating should stop melting.

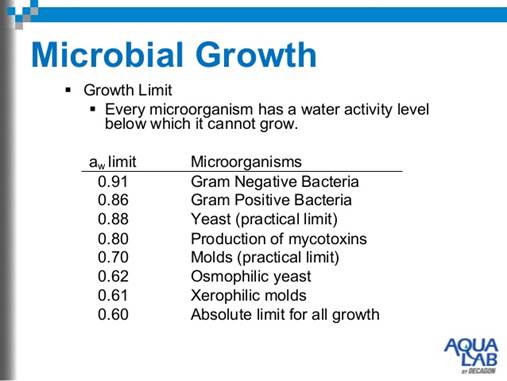

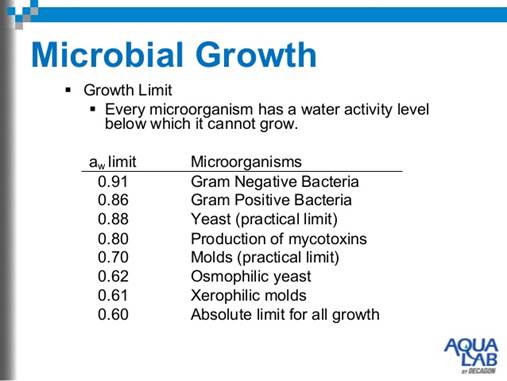

If you have an active water meter, you’re looking for around a 0.7 reading.

Use less water and/or more sugar in your formula and the coating should stop melting.

If you have an active water meter, you’re looking for around a 0.7 reading.

Thanks!!!

I just wanted to take the time to express how grateful I am for everyone who has contributed To the information on this thread. Has made my learning curve a lot shorter than it would have been, without y’all. I found that an extra layer of plumbers tape comes in handy for the threads on the squeeze bottles. The sous vide and ketchup bottles are godsends. Thank you guys!

How much potassium sorbate?

That’s a loaded question…so I ask you what’s your mix recipe…Iv recently increased (doubled) amount we use because it’s such a small amount compared to the mix…are you making it yourself or premixed from lorans…

I plan to use the Killa recipe @yycmmj wrote up. I’ve read 1% is a good place to start.

I’ve been using a gram of the Lorann ‘mold inhibitor’ (potassium sorbate) per batch and doing fine

Is 2 teaspoons per 5# of finished product for loranns.

Cross multiple.

One question that I haven’t seen thoroughly answered on this thread. When does the homogenizer come in? At the end before placed into the bottles? I want the most accurate dosing possible

When would the homogenizer make the most sense? My thought would be after all ingredients are added before placing in molds…

FYI: you can search keywords within a thread…

Thanks boss forgot about that lol

if you dilute your extract with a little MCT (1:1 up to 5:1) and homogenize that, it is a lot easier to get the goodies well dispersed in your gummies.

an immersion blender does well for the diluted extract into gummy mix (thanks @MillerliteRN)…the right weapon for getting the extract into the MCT depends on scale, budget, and regulatory environment. you can get the job done with a dab tool if you’re playing with a couple of grams for personal consumption. for larger amounts you can use an oster blender. see: Biomass Grinding at various scales? - #22 by cyclopath. or a high shear homogenizer.

if you’ve got money to burn & are aiming at cGMP then dual axis centrifuge is a really fun toy…Homogenizer temp settings - #6 by cyclopath

You might wanna ask @qma this question as I think he trashed a homogenizer tip making gummies.

That was going to be my next question. Wouldnt it make sense to homogenize the whole mixture once the distillate is added? So it’s dispersed evenly throughout the whole mixture, But like you said it messed up a probe.

That’s bad ass, that you know of the slurry. That was my second biggest gamechanger in that adventure. Why not just use the normal blinder container here? The slurry setup would work with my microwave tech, removing the band and blade…I have several blades I might give it a try but one quart at a time seems daunting.

Did he trash the cat scientific one? They keep telling me that their drives keep on breaking because of gummies

you would have to ask him but i remember him being upset that day. id imagine it was the Cat scientific one but i think that was the first run of gummies and last run he made as it wasnt a good experience…

@cyclopath I think I miss read your last post. Your suggesting the slurry setup, to mix the solvent and disty? Not the gummy mix?

Does this work better than hot plate?

I think I see a few advantages if that’s the case.

Edit…even on low to mid scale volume

slurry setup? now I’m confused ![]()

the dual asymmetric centrifuge can melt your store bought gummies for you and homogenize your distillate into the resulting goo.