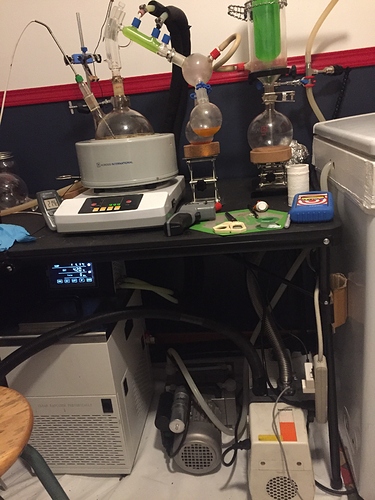

My S.P.D rig won’t seal and I’ve tried everything Teflon disty supper expensive grease pleas someone help us??? It’s an OSS 2L set up with a Alcatel 2021i changed pump oil it gets 9 micron but hooked up to the rig she’s a dead duck 600 to 900 mic at best and it won’t hold it:( I’m stuck lol

Try whipping out every fitting to bone dry. Apply light vacuum grease. Clockwise screw the male to females in. Clamp. Use jackstand to snug fit. Get a needle valve and slowly vacuum down.

Moisture and grease is the enemy for glass seals.

Check vacuum ports they maybe leaky

Thank you so much! il try that out for sure getting a little frustrated I’ve bin at it for a few weeks now

Check your port by your pump. Any cracked connections?

We all been there

Not that I can see I’m just letting my run cool down right now then I’m gonna disasmebal my rig disconnect the pump drain it and do a thurow inspection on it

Replace thermocouple adapter with better quality version or thermowell.

Try dry testing the vac level of the system. Usually if you play with the joints you can see the gauge jump/drop in bad ones. They shouldn’t change at all when twisting so if you see the gauge budge it’s a good sign that is your leak.

Can you send me a picture of the unit? Is any of it on gl connections? Tubing? Where are you measuring vac? First or second pass. Whay are your temps and pressures youre seeing an issue with. Dm me all the things

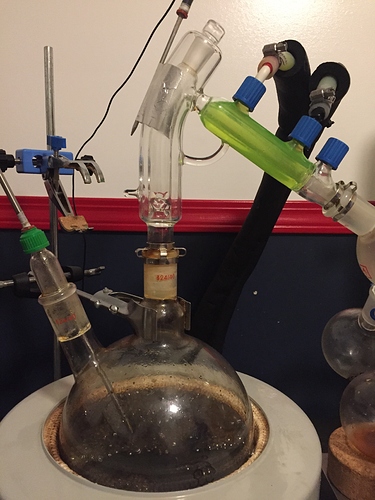

I cant tell from the photo but it looks like the oring is outside the cap on the thermocouple adapter. It should be squished between the cap and the adapter glass to snug fit. The gl-14 connection on the back of your cow. It has a red oring inside that seals the plastic to glass. Make sure that isnt split. Replace if it is. Or i like to stretch the tubing over the glass cow thread area. Makes a better seal… but obviously doesn’t come off without force.

Before applying grease, i like to wipe down both sides of the joint with acetone and a papertowel… acetone dries with no residue and it removes even fingerprints so that it’s a great seal.

Thank you so much man and I have a stainless below from the pump with kf25 conections then go’s to hose nipple/ bullseye digivac reader then to gl16 on cold trap then to cow Heres a way to narrow it down. After the run, or cool to 120C and open. Take the tubing off the back of the cow, cork it with a sharpie or something that will stop the flow, pull vac on that and see if it goes down as it should, if not, the problems before your cow. If it does, then it may be that thermocouple or the gl-14 off the cow

Thanks il try that for sure ASAP

Ya i can see your oring, the oring adapter is wrong, ill do a vid and show you

Check this out, oring in the right location. No tape

There’s a clear one on the inside of the adapter tho should it be the red one

Here This is the thermocouple way

Oring on glass, screw on cap, slide in thermocouple to proper length, tighten the cap snuggly.

Clear or red on the gl doesnt matter, just look for splits in the rubber.

The gl-14 will have a little red or clear glasket, one is viton (i believe) the other is silicone, either works (more or less) for this application, it needs to be there, we often consider gl-14 adapters to be throw aways so when the rubber splits… well… thats how you get pregnant… ![]()

Also, switch the fluid in your cold trap to acetone and add dry ice, it needs to be super cold to condense anything trying to get by, isopropyl or ethanol work too but acetone is best…

Fill 1/3 with acetone, powderize or use very small pieces of dry ice… add one tiny piece at a time as they tend to bubble the acetone alot with the releasing co2 gas. Once it calms down after multiple pieces are staying solid and not bubbling… then fill to the brim with dry ice, carefully top off acetone to within 1/4” of the lip.