Media Prep - Bake.pdf (164.7 KB)

I’ve been getting a lot of questions about media prep lately. This infographic is from my lpg chromatography (advanced crc) SOP and is a critical step before using any clays or adsorbents. The recommendations in this SOP are tied to the rest of the SOP, which does include blending your media perfectly (no layers in my columns) but that’s a separate topic for another thread.

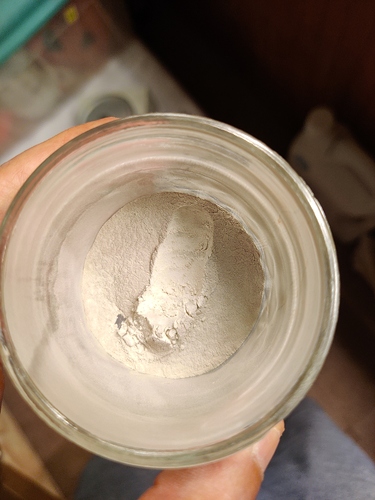

What I did want to address is the ‘layer’ of crud that people are noticing on top of their silica and clay when they start baking it. This is totally normal - and totally preventable.

When you bake your media in a closed space (especially clay because it holds a LOT of water) that water will reflux inside the closed space. Your oven might be 200c, but the water vapor will still recondense inside the oven when it has nowhere to go, and as a result any solids in that water will precipitate out. It will rest on top of the media and usually look dark because, well, it’s dirty. Common contaminants are: loose media (carbon & clay) salts in the air, misc dust, and especially weed particulate. If you use your oven for both media and hash (I dont recommend this) then you could easily end up with residual hash getting sweated off the walls and onto your media too.

Your media will not ‘burn’ until you reach temps of almost 2000c so you cannot damage the media by baking it - but of course you dont want to pour that layer of salty weed dust into your chromatography column either! Your media is still totally fine to use - just scrape that ugly layer off the top and throw it away. If scraping it off is not possible, you can also wash it off, but that’s a lot more effort than I would probably invest.

To prevent this crusty layer from happening in the future all you will need to do is clean your oven completely after each use and stay on top of wiping it down/venting steam during the baking process.

Wear a mask, gloves, protective clothing etc and wipe your oven down, then vac it dry, for at least 2 or 3 repetitions. A clean oven cant sweat dirt all over your media! The next step is to make sure you are regularly venting your accumulating water vapor during the baking process. Open that oven and wipe down the water all over the doors/sides etc at least once while baking your media. Leave your vent port all the way open so the water vapor can escape out of the back. (*adding a check valve here will help prevent moisture outside the oven from getting inside! Check valves are cheap and if you live in a humid area you will want these on all your ovens anyway) It’s also very helpful to mix your media regularly during the baking process to encourage moisture to evacuate faster.

Hope you guys find this helpful! I’m not great at responding quickly on the forum (I tend to end up here in the middle of the night after my toddler is in bed) but I will try to stay on top of your questions on this thread!

Shameless plug: my next online webinar for lpg chromatography will be held on August 8th. I miss teaching in the lab SO MUCH but for now zoom webinars are holding us over. Anyone who takes my zoom webinars will get a discount matching the webinar price for any live lab classes in the future. And if you’re a GLG member you only pay service fees! (check the glg website for your discount code)