That’s not how it’s made, not at all.

Magsil works with chemistry. Making from dirtnor dust isn’t effective. Magsil has a silicate and a special shape, then the magnesium ioms are attached via a process and those also have a special shape around the silica.

I mean if you read the patent it’s speaking specifically about making a highly active magnesium silicate for the purposes of defolorizing oils

That sounds like the exact reason I need to make magsil, I’m not using it for PR I’m using it for cleaning up hazy and darkened oil

Your understanding of chemical activation seems to center around carbon, and is very much basic and rudimentary and has nothing to do with activating magnesium silicate- which has little to do with porosity but everything to do with zeta potential and electrical charge

Educate yourself, we live in the Information Age: Zeta Potential - YouTube

ALSO : I didn’t think that activation of magsil in this case was possible just by heating- I know that some compounds are made more active by heat alone but obviously this one is not- if it was as simple as baking out fryer filter oil then everyone would do that- you are showing just how little you know and clearly only seek to stalk me around the forum proving exactly how poor your comprehension of this work is while allowing me to further detail and explain why I do so well in my work

Poor tortured soul, I hope you see the forest for the trees soon, before it’s too late.

So if you read that patent @spdking we are taking about synthesizing highly active magnesium silicate from aqueous sodium silicate, this is performed via several methods but they all seem to involve supersaturating your sodium silicate solution and adding sodium chloride, then adding a magnesium salt such as magnesium sulfate and another chemical while applying heat to precipitate out a magnesium silicate which has superior effects when applied to oils as a decolorizing treatment.

This is called chemistry. Why are you trying to even argue with me on this?

This is correct

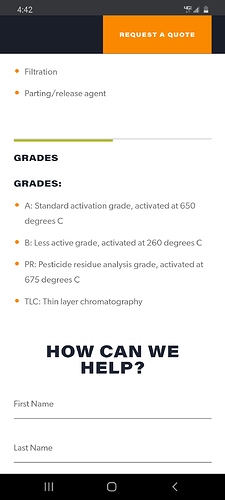

If you pull up US silicas website you can read about the different grades of magsil and florasil

I believe the different activation Temps give a different shape / PH to the molecule

I remember seeing this video awhile back, I wonder what that would do for crc lol.

When you synthesis it, you do not need to use heat to activate it- that’s the thing I’m trying to explain here: it’s dirt cheap to make

Hello all! New comer here ![]() Been lurking for a month or so

Been lurking for a month or so ![]() interesting convo I think regardless you have to expose the mag.sil to different heat levels for specific activation type. synthesis alone does not create activation the activation helps to create a matrix of pores, which help to exclude some molecules based on size and and the polar property of the mag.sil helps to retain other compds

interesting convo I think regardless you have to expose the mag.sil to different heat levels for specific activation type. synthesis alone does not create activation the activation helps to create a matrix of pores, which help to exclude some molecules based on size and and the polar property of the mag.sil helps to retain other compds

I think kingofkush posted a link to us silica which shows different heats for activation

Right so, if you read the patent I posted, and the two other links above- it is quite clear that the synthesized magsil is activated as a process of its synthesis

And again I will post the patent describing the synthesis of an activated magnesium silicate which does not describe any calcination process- synthetic magsil is activated without heat.

I see ![]() the Wikipedia article does say the synthetic version is amorphous which means it does not have long range molecular ordering - which is what we see in everyday glass - and that it usually has porous.i imagine in some cases it may not have pores. I think in cases where there are pores its a question of is it the right specifications for the intended application. If not activation maybe required

the Wikipedia article does say the synthetic version is amorphous which means it does not have long range molecular ordering - which is what we see in everyday glass - and that it usually has porous.i imagine in some cases it may not have pores. I think in cases where there are pores its a question of is it the right specifications for the intended application. If not activation maybe required

650c is easily reached in a glass kiln.

Heat is used to activate the magsil and give it the properties you want. Why don’t you call carbon chem and ask, or better yet call us silica. That’s what I did and they told me exactly what was said above

Read the patent

He describes no heat activation in the invention and it works for color remediation, which is my goal.

Sorry gents didnt mean to cause trouble ![]()

You didn’t do anything, some people just think they know everything and can’t even do any research for themselves

magnesol is also magnesium silicate

It works great for color remediation but robs your yields

Theres a reason they activate it bro