My max with a poolstick compressing without a single void is under 3. If i packed 5 lb id be yielding 300 to 400 easy… numbers seem off

Ill get that SS packer and give a try

Pack the tube like that bitch owes you money!

![]()

![]()

![]() Makes 2 of us.

Makes 2 of us.

Heres the packer next to my 6x36 and 4x48 for reference

Heres the work end

Heres the handle

Heres what we used to use i think its a 2" wood dowel

it weighs about 11# and it was not cheap! Even from buds. The one from XD looks chincy IMO but u get what u pay for.

Are any of you testing your spent biomass? I feel like some of this crazy packing must cause some serious channelling. It certainly gave me issues in my co2 rigs.

Running the same bio, I haven’t noticed any yield difference between packing 7.5lbs vs 10lbs in the same space

I’ve seen extraction efficiency drop by 1% when going from 3-6” columns though

My experience says an under packed column has a better chance of channeling and poor yeild than a very tightly packed column.

I’m with @TwistedStill, the middle ground is the worst. If you’re gonna pack it tight, you better pack it mega tight but if you do, it runs better than a loose fill. With CO2 it’s worse because once a channel start, the constant fluid flow opens up the channel/fissure and then you’re fucked lol

Hey my friend, im just making it back around today to answer some of these questions. Im using 70/30 butane propane. Running 10 tubes a day and not waiting around to evacuate all the gas from my columns, could the butane be breaking down or staying in my columns so I end up with a propane heavy blend? I run about 450 pounds of gas a day and I leave behind, about 100 pounds of gas a day. Yes, I have a loss 9f about 100 pounds per day. I have made peace with and deem that an acceptable loss and expense considering input and output per day. With all of that said, isn’t heavy propane a 10 to 1 solvent? My research tells me, guys are running propane for the increase in pressure. With nitro, a passive/active hybrid, my blazing recovery times and my ability to push a hundred pounds of material per day, should I be using a straight n-butane?

Thanks my friend, much appreciated!!!

message was directed at dred_pirate.

Thought I was replying directly to him.

So, update. Bottom fill, no change!

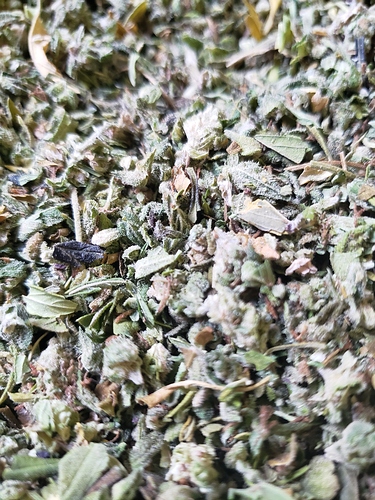

As for, is the material actually 20 plus percent, yes. I have been training my farmers and trimmers for years on the simple concept, sticks, stems and waterleaf don’t add weight, they lose you sales so, yes, straight short and curly, sugar and smalls. See pic below. All sugar and smalls.

As for the purpl tester, I carry a USB blender with me and homogenize the sample to dust before testing and I test 5 different pulls and do an average.

The grinder I use will easily grind to dust as well so. What goes in the tube as been heavily ground as well. Again, messes up color but crc happens secondary and down stream so…?

Grinder, see pic below.

As for pack, light pack, pack like the bitch owes me money, tried every version and no change at all in yield. 8 to 9 everytime

Someone made mention of hose and manifold sizes. Im 3/8 injection, 1/2 for my pumps on hot loop only and 1" on my passive side. There was a comment about being undersized on the inlet to my pot…im 3/8 all the way through. Please explain why and how im undersized and ill happily go up to 1/2 on all. I have a load of hose, fittings and a hydraulic crimper so, easy peasy.

A upgrade to 1/2 injection manifold and all the way through but, all my showerheads and bowl reducers are 3/8 so, in order to get a full 1/2 all the way through all that has to be changed.

Thanks to all for chiming in and in my heart of hearts I feel its down to one of three things.

- Channeling in the tube, not sure how to fix.

- Wrong blend of gas for my application. Been using 70/30 since the days of 3x48, pre nitro so maybe thats an obvious im missing. Again, easy fix.

- If my injection and my exit from tube to pot is undersized, ugh, ill bite the bullet and go to 1/2.

All opinions and advice appreciated

And, product before and product post crc pics as well. I grind hard so, kills my color even on fresh material.

Pizza gang

It takes 25Lbs of solvent to fill your material column, and then you only push through another 10lbs?! 4:1 solvent to biomass is one thing but the way I was taught is column volumes, and to run min 3 - 5 columns worth of solvent through when running at very cold temps and more with higher propane blends.

You could soak longer or run/soak warmer to get more out of your biomass to the point of needing a dedicated dewax column or run more cold solvent volume.

You sound quite tooled up, throw together a 1lb system and trial a bunch of parameters quickly.

Sound advise!

Why do folks always try and optimize at production scale?

Certainly a common phenomenon where people try running before crawling, there’s also the (almost more) common phenomenon of things not working at scale that worked in pilot. Same line of questioning OP, what’s changed in ratio from when you ran on a smaller scale?

Edit: those pizza boxes are brilliant lol, wish I’d have thought of that

Agreed. Not working at scale when the pilot/prototype worked flawlessly sucks…and does happen way too frequently

FWIW, scale up in cannabis is generally a lot more linear than some other things. Like cooking rice. Ask me how I know…

Lots of talk about column packing. I present to you, The Iron Fist:

I’ll bite. . . tell me about rice

Do you have take the top tri clamp off each time to add a handful?