Hi All,

I recently ran some 22% CBDa Hemp (according to the COA) through a commercial CO2 extractor.

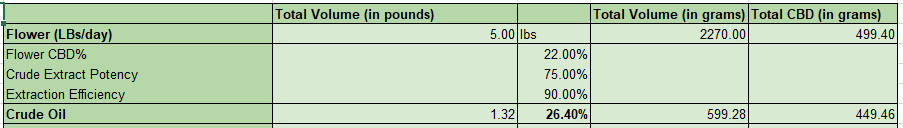

The hemp weight was 5 lbs, which means there should be 500g CBD in there.

Using sane assumptions that the crude we get out is 75% CBD and extraction efficiency is 90%, I should be expecting a 600g yield each run.

(I used a modification of

@Future’s

Hemp Processing Spreadsheet

However, I was getting somewhere around half that. What gives? I’ve already sent out samples of the ground hemp pre and post-extraction, as well as the crude.

There are a few things I think might be happening:

- I should have adjusted my recipe for high-CBD hemp, and there’s a lot left in the starting material.

- The hemp isn’t 22% CBDa

- The crude is 150% CBDa

Lastly, anyone know of good resources/formulas for tuning CO2 extraction recipes?

When you say crude do you mean winterized or no? How long at how many g/min did you run the material?

By crude I mean unwinterized output from the CO2 extractor.

I’m not sure what flow rates we run at, because the recipes are pretty basic. Just simple temperature and pressure setpoints at extractor, separator, and CO2 tank inlet/outlets. Flow rate is definitely a variable I am working to derive from the info we have available.

We have a relatively unique machine that I really want to keep anonymous, but let’s say it’s designed for high flows, and it has a 2 hour start to stop time.

1 Like

Sounds like you missed most of the extract. I’d recommend testing your biomass before and after extraction to discern how much you’re missing.

That’s my conclusion too. Tests are on their way.

The weird thing is, I did a second run and it yielded almost nothing.

What temp/pressure are you extracting your main cannabinoid fraction at?

Hey man, I have tons of experience with Co2. Feel free to hit me up with questions. I’m down to share my recipe.

Kylan

(970) 420-8186

3 Likes

Might want to go a bit higher pressure, 25 bar or so. Acidic cannabinoids come off slow with CO2 by itself.

1 Like

Agreed, CO2 is slow as hell for acidic cannabinoids like the CBDA you are trying to extract.

If the extractor company told you 2 hours, that is probably for decarbed material, and a little optimistic. Run it at least 4-6 hours and see what you get. Ideally you would take a sample every 30 minutes or so and see when the returns are no longer worth your time.

You might also find that CO2 can partition THC/CBD enough to get you under an arbitrary legal limit of THC.

I was always under the impression that biomass should be de-carboxylated prior to CO2 extraction to increase extraction efficiency and speed up the process.

Hey, I was wondering if this offer was still open! Lol