Finally got to power on this EX80 I installed with Iron Fist, for Knotty at Primo Cannabis last week

Stoked to implement my simplified hybrid (Active + Passive) concept and see it work with a proper chiller

I personally don’t love mirrored systems as they present a logistical challenge to plumb safely without any hoses as tripping hazards… and for a few other reasons…

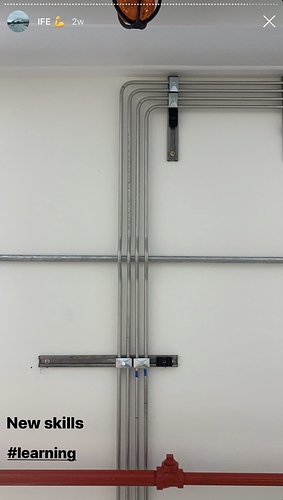

So I elected to plumb everything overhead with stainless tubing and make drop lines down to the components. Make it as simple as possible to operate with no hoses to swap or disconnect. Hot gas boost from either pump, extra take-offs for nitrogen, remote port to send propane vapors, extra vacuum ports for the pump located outside the room. (But still exhausts into the room). Every component of the machine is bonded to ground - new WA requirement after the Sticky Budz incident - making things as safe as possible!

Kept 360 degree access around the system which is nice!

(the nitrogen tank isn’t secured here - they’re upgrading the bracket for something bigger.)

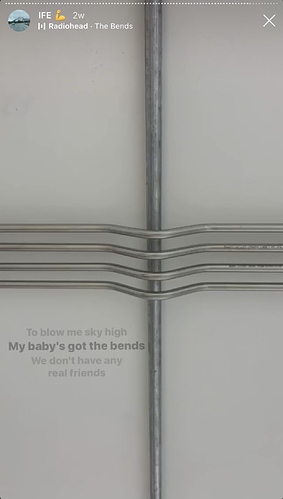

Had to dial in the bending skills for some three point saddles on two planes!

Fun stuff learning how to make everything lay perfectly square… on the ceiling