Admins, please know this was also shared in a separate thread, however I believe it may warrant a new topic in and of itself.

I am sharing this, knowing I’ll be ripped to shreds, yet that is the hope - I truly implore more, better educated and equipped individuals and firms to consider looking into this. Theoretical isomerization of lactones is possible as well. Yangonin and kavain have a great deal of potential to either generate revenue or simply “fun” for the users out there.

Please criticize and facilitate/help.

Abstract:

This study is aimed to showcase and request aid to develop a more refined process for extracting and isolating kavalactones from kava root powder using supercritical carbon dioxide (CO2) extraction and subsequently purifying the crude extract through winterization and thereafter utilizing a 5L vacuum short path distillation to obtain a specific kavalactone distillate.

The process was straightforward and relatively basic for most organic extraction operations, nonetheless it involved three main steps: (1) carbon dioxide extraction of kava root powder, (2) crude extract purification through winterization, and (3) distillation of purified crude extract to obtain a kavalactone distillate.

The results of this study showed that the supercritical CO2 extraction of kava root powder was successful once it yielded an orange/waxy crude extract with HPLC testing showing approximately 75.8% kavalactone concentration. The crude extract was then subjected to standard winterization to remove impurities. The purified crude extract was then distilled using a short path distillation apparatus to obtain a kavalactone distillate with a theoretically higher purity and less aromatic/flavorful yield.

Overall, the developed process provides a viable method for obtaining a kavalactone distillate from kava root powder. The use of supercritical CO2 extraction and short path distillation ensures a solventless/high purity end product, which could have potential applications in the pharmaceutical and nutraceutical industries. Further studies are requested so as to help optimize the process and scale it up for commercial production.

Introduction:

Kava, also known as Piper methysticum, is a traditional plant-based medicine used in Pacific island cultures for its relaxing and calming effects. Kava contains a complex mixture of bioactive compounds, including kavalactones, terpenoids, flavonoids etc., which are thought to be responsible for its anxiolytic properties. In recent years, there has been a growing interest in the pharmaceutical and nutraceutical industries to develop kava-based products for various applications. However, the use of kava has been associated with hepatotoxicity and other adverse effects, prompting some regulatory agencies to impose some restrictions on its use. Therefore, there is a need to develop safer and more effective methods for extracting and purifying kava’s psychoactive compounds.

This study and procedure aimed to develop a rudimentary process for extracting kavalactones from kava root powder using supercritical carbon dioxide (CO2) extraction technique and subsequently purifying the crude extract through winterization and lastly, short path distillation to obtain a kavalactone distillate. Supercritical CO2 extraction was chosen as it is both theoretically efficient in separating the lipophilic kavalactones, and CO2 also has the least likelihood of inducing hepatotoxicity or inducing liver conditions. However a solvent was introduced via winterization, yet it was subjected to rotary evaporation thereby removing any residual solvent from the mixture (still, further research is required). Short path distillation, on the other hand, was used as a process to separate the volatiles and purify the heterocyclic ester compounds in fractions based on their boiling points while under a vacuum pressure reduction.

Materials:

-

Kava root powder

-

Carbon dioxide (CO2) gas

-

Super critical fluid extraction (SFE) apparatus equipped with a high-pressure CO2 pump, extraction vessel, separator, and CO2 recovery unit (Ethanol injection

-

Winterization solvents, such as ethanol: Filtration sleeve&Vessel: Rotary Evaporator

-

Vacuum pump/oil/mist-filter

-

5-liter short path distillation apparatus, including the following components:

-

Heating mantle or hot plate

-

Vacuum pump

-

Cold traps (two)

-

Condenser

-

Thermocouple probe

-

Receiving flask

-

silicone oil or other heating medium (capable of safely maintaining 200C) for the circulating bath

-

Procedure:

Kava root powder is extracted using supercritical CO2 extraction to obtain a crude extract.

The crude extract is dissolved in a nonpolar solvent and chilled in a safe vessel to -20°C to -80°C to remove impurities through winterization. The solution is then filtered through a filter sieve/paper to separate the precipitated impurities from the solution.

The crude mixture is then taken to a rotary evaporation unit which utilizes silicone oil within the hot bath

The purified crude extract is subjected to short path distillation to obtain a kavalactone distillate with high purity and consistent composition.

The distillation process can be repeated several times to obtain a specific kavalactone distillate with high purity and consistent composition.

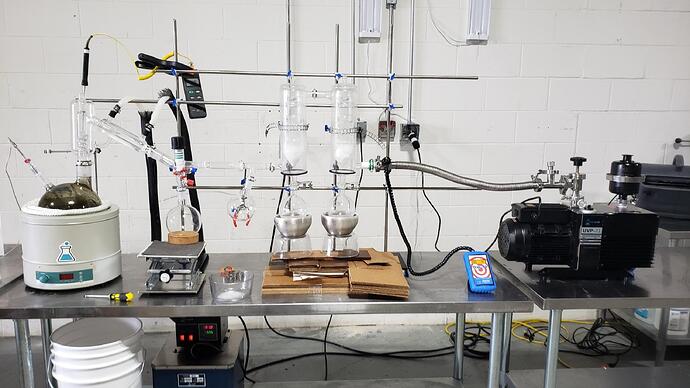

The actual process involved three main steps: (1) carbon dioxide extraction of kava root powder, (2) crude extract purification through winterization, and (3) distillation of purified crude extract to obtain a kavalactone distillate. An SFE apparatus was used to extract kavalactones from kava root powder using CO2 gas as the solvent. The winterization process was standard, i.e.: dissolving the crude extract in a suitable solvent, namely ethanol, then using a rotary evaporator - remove all solvent from the mixture. The purified crude extract was then subjected to short path distillation using a 5-liter flask filled to approximately 2.3L worth of material, it is also worth noting that borosilicate raschig rings were packed into the distillation head. Lastly the condenser temperature was tailed/heated using a recirculating bath of hot silicone oil, and two cold traps were used to prevent any loss of material which could be studied and/or corrosion of the vacuum pump itself throughout the course of distillation.

Findings:

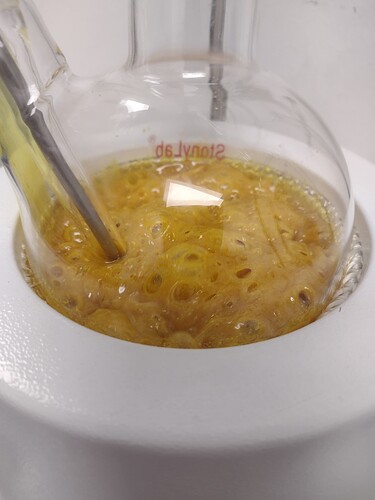

Composition: The composition of the initial CO2 kavalactone extract yielded 60-70% total concentration by volume. The composition of the distillate is awaiting results. (Standards can be purchased online, although they are relatively pricey)

-Crude waxy extract

-Kava distillate in receiving flask/on stirrer

Characterization: The kavalactone distillate should be characterized using spectroscopic techniques, such as infrared (IR) or nuclear magnetic resonance (NMR) spectroscopy, to confirm the identity of the individual kavalactones present in the sample. BUT I DO NOT HAVE ACCESS TO THIS EQUIPMENT

Other observations: From the moment of extraction the initial extract the product was dark orange in color and waxy/pasty in consistency. At room temperature, the extract was solid, yet the slightest amount of heat would gradually melt the oil. Winterization yielded a brighter orange color once cooled to room temp, immediately following the rotary evaporation it was a dark reddish color. The heads of the distillate were very light, almost like a pale-yellow - the mains were darker and similar either amber or a reddish amber, lastly and as expected, the tails were extremely red.

Omissions/Final notes:

It must be acknowledged that a great deal of data has been intentionally omitted from this report; because of the nature of intellectual property which is pending certain filings. However, the operators and facilitators of this experiment wished to share the relatively simple nature and straightforward process which yielded an anecdotally “effective” product, to those who may wish to attempt this for themselves. All of this was done in the hopes of improving the market and accessibility of this root and its lactones. We are aware that we have our own intellectual shortcomings, we will never claim to be the best, yet we certainly tried our best nonetheless. Please consider contributing to the research rather than criticizing, we wish to improve and learn ourselves too.

Credits to operation(s) and writing: Daniel H. (KING KRUNK) & Ben W. for consultation and review (Dodi hemp/Indy extractions)

Equipment and materials needed:

PPE

Short path distillation apparatus

CO2 extracted kava

Recirculating heated bath

Heating mantle

Vacuum pump

Thermometer

Weighing scale

Stirring rod

Dry ice

Isopropyl/Propylene glycol

pH meter (optional)

-5L SPD used

Procedure:

Set up the short path distillation apparatus according to the manufacturer’s instructions. Make sure all joints are secure and the apparatus is clean and dry.

Weigh the desired amount of CO2 extracted kava and add it to the distillation flask.

Connect the distillation apparatus to the recirculating heated bath and turn it on. Add high-temperature silicone oil to the recirculating heated bath and set the temperature of the bath to the desired distillation temperature.

Prepare the cold traps by adding a layer of dry ice to the bottom of each trap, followed by a layer of isopropyl 90%. Make sure the traps are securely attached to the distillation apparatus.

Gradually introduce vacuum into the distillation path using the vacuum pump. Monitor the vacuum level readout and adjust the vacuum as needed to maintain a consistent level.

Once total vacuum has been achieved, introduce heat through the heating mantle.

Set the temperature of the recirculating heated bath to be 20C lower than the temperature of the solution in the distillation flask.

Monitor the temperature of the distillation flask using a thermometer. Once the temperature of the solution reaches the desired temperature for distillation, introduce low RPM stirring using the stir bar inside the distillation flask.

Monitor the distillation process closely, collecting the fractions at the appropriate boiling points. Once the temperature of the distillate reaches the theoretical boiling point of kavain (172°C at 150 microns), lower the temperature of the condenser to be 40C below the temperature of the solution in the flask.

Continue the distillation, monitoring the temperature closely and collecting each fraction at the appropriate boiling point. The theoretical boiling points of methysticin, yangonin, and desmethoxyyangonin are 190-192°C, 220-222°C, and 230-232°C, respectively.

As the distillation proceeds, continue to add dry ice to the cold traps as needed to maintain the temperature of the iso-slurry.

Once the distillation is complete, turn off the heat source and allow the apparatus to cool.

Once the apparatus has cooled, carefully remove the receiver and transfer the distilled kava to a clean, airtight container for storage.

(Optional) Measure the pH of the distilled kava using a pH meter. The optimal pH range for kava is 6-8.

Label the container with the date, batch number, and any other relevant information.

Proof of theoretical boiling points:

Theoretical boiling points are typically calculated based on the vapor pressure-temperature relationship of a substance. In this case, we assume that kavain, methysticin, yangonin, and desmethoxyyangonin follow the Clausius-Clapeyron equation, which relates the vapor pressure of a substance to its temperature and enthalpy of vaporization. Using this equation, the boiling points of the four compounds can be calculated based on their enthalpy of vaporization and vapor pressure at a given pressure (in this case, 150 microns).