@710enigmatic

I will deff swap the clamps and freeze the material/solvent/rig to at least -25f. Thanks for the heads up on felt filters and mixing keif to avoid clogs!

Could I ask for specifics about the co2? I’ve seen many people warn not to and thus probably just won’t… BUT… an engineer friend that is VERY knowledgable about heat-transfer, thermal dynamics, and fluid dynamics (employed by siemens to work on multi-ton turbines) walked me through the theory and some of the math, and his conclusion was that it would be easy and to reliably vent residual co2 with negligible butane loss. I don’t claim to understand what he knows, or what the extraction community does, I am trying to wrap my head around any theory or anecdotal information available because it will almost certainly come in handy for other similar situations.

@BigM

Thanks friend, I feel like I at least understand many of the decisions I need to inform myself about!

Fortunately, I’ve already distilled the solvent several times now, partially just to get used to some of the equipment/processes. I will keep an eye on the quick-connects, if leaks develop is there an o-ring to replace or should I just replace the whole thing?

I hadn’t thought about shelter, actually, I have been in a clearing in between a few shelterbelts in a consistent 20+mph wind. Less wind would be nicer to work in, but I wonder if the wind and lack of corners helps prevent an explosive density of gas from accumulating. Nothing electrical is out there yet, but I’ve been debating bringing out some aquarium heaters for the collection chamber bath, would that be a safety concern?

@thumper

You are right of course, this account is brand new. When I started reading this was one of many forums populating dozens (hundreds?) of tabs. I just created an account by linking my gmail, which is my full name. So I made a new account that is not literally my legal name before posting. I hope that you don’t feel I’m wasting anyone’s time by neglecting to research to the best of my current ability.

@StoneD

I just get a few smaller beverage coolers, using a larger cooler like you suggested makes a lot of sense because it would increase thermal capacity. I’ll get on that. Is the smaller cooler alright for cooling because it’s easy to just add more dry ice?

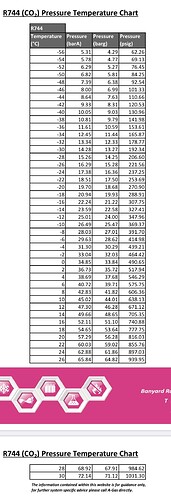

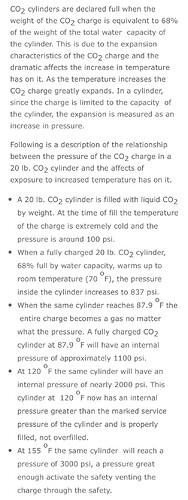

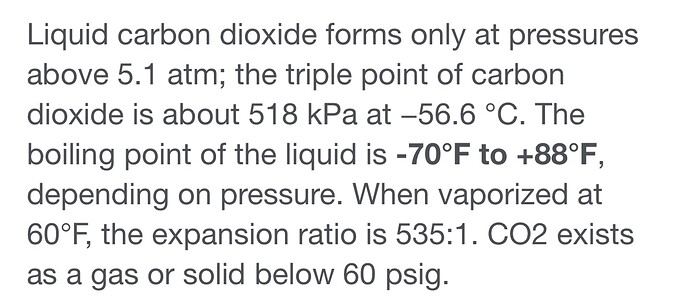

It sounds like you are saying that the co2 issue isn’t related to vaporization of fluid, but expansion of gas. That helps me understand why a pre-purge co2 vent won’t solve the problem entirely. My (frankly uninformed) sense is that the increase in pressure would only be several dozen psi, I’ll read up on it ![]()

Thanks for the help!