@hambread you’re correct, I would argue the same thing and I had the same thought, I showed it to our tech and he said pretty much exactly what you said.

Still, I’ve always been defiant. I must learn for myself. It looks like Ammonium Bicarbamate could be the potential focus here? I was mistaken, in that; DEA and MDEA do not “isomerize” or turn into NH3 though I’m not sure if I said that verbatim in my postings above, its possible I did, but definitely what I guess I was thinking initially, and turns out the MDEA was just a clue. Its the way the MDEA and DEA chemical solvents carry over the NaOH which becomes mixed with ammonium bicarbonate granules and some how “leaches” some kind of trace back into the output stream.

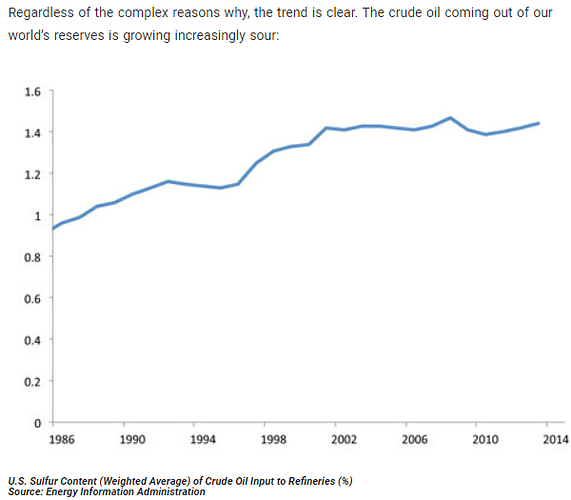

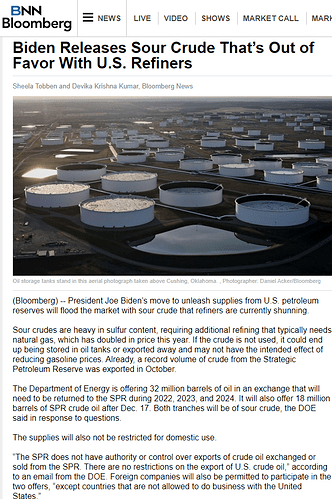

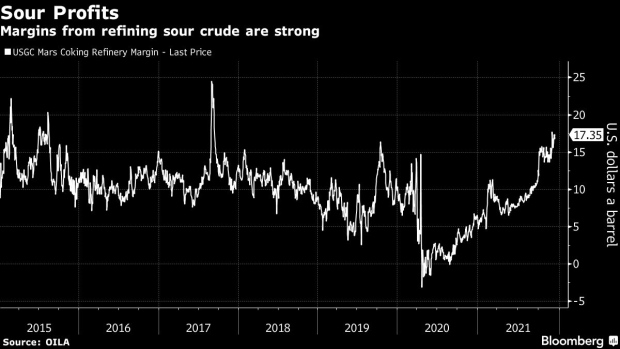

It seems like the ONLY thing now is finding out exactly how sour is the crude? If they used sweeter crudes prior to the global pandemic and changed over or added on sour crudes then you would see this affect, possibly, and be able to determine “its the gas”.

I wanted to find something conclusive but just couldn’t do it; there are market reports behind paywalls regarding MDEA and no doubt contain the information I would need to draw a correlation but I had to stick with public access information.

Here’s what I found below;

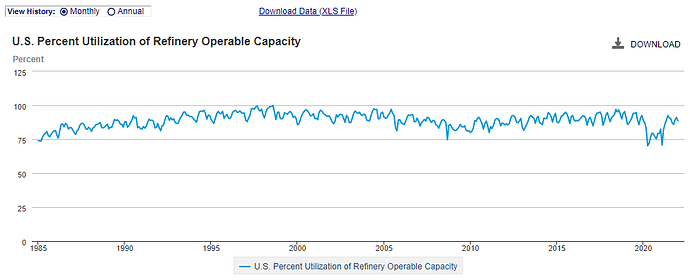

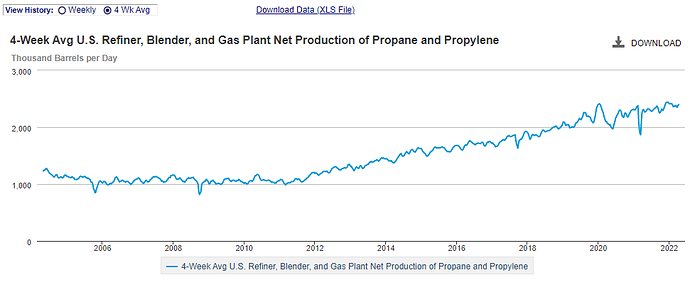

EIA statistical information; paints a picture of slump in operable capacity at the refineries but an uptick in supply of our product segment. (the chart says Propane/Propylene but it referes to ASTM D1835-20 standards which includes all the LPG’s)

So you mean to tell me output product increased while operable capacity went down or remained stagnant? HOW…

original link here

Here’s the paywall report on MDEA global markets outlook 2022;

https://www.precisionreports.co/TOC/19646475#TOC

We’ll have to make do with this instead; original link

WASHINGTON, Nov. 16, 2021 (GLOBE NEWSWIRE) – According to a new report by Vantage Market Research, the n-methyldiethanolamine (MDEA) market is expected to reach USD 1000.2 Million by 2028, growing at a CAGR of 15.1% from 2021 to 2028. The increasing demand for carbon capture and sequestration (CCS) coupled with demand from oil & gas industry is anticipated to fuel the growth of n-methyldiethanolamine (MDEA) market within the forecast period.

original link here

Detailed description of Merox treating process and what I’ve learned;

Caustic Soda = NaOH (Sodium Hydroxide),

Removes H2S and most but not all CO2, and requires emissions are higher in oxidizer for regeneration.

;added with;

Chemical Solvent / Catalyst used in Treating of Caustic = DEA (diethanolamine), and or MDEA (methyl diethanolamine)

Removes some H2S and all CO2 slowly, and is separated via reflux condenser for recovery. DEA offgas emission output is higher compared to MDEA with no output/off-gassing required.

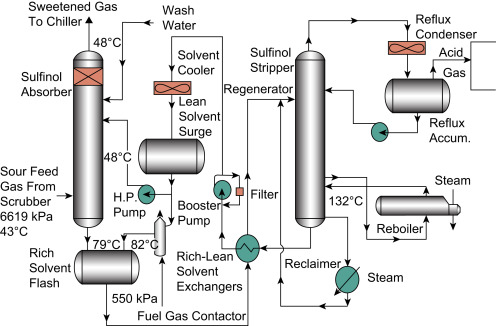

Sulfinol (a mixture of sulfolane, diisopropanolamine or methyl DEA, and water)

Regenerator IN = Rich amine solution (rich solvent) = chemical solvents with mercaptans catalytically oxidized to disulfides

Regenerator OUT = Lean amine solution (lean solvent) = recovered chemical solvents from extracted disulfides are seperated via reflux condenser

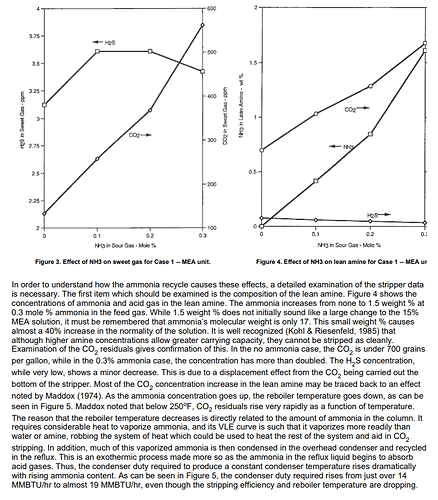

Small amounts of ammonia can cause serious problems in some amine sweetening units. These problems are usually traceable to a complex of ammonia with CO2 in the stripper. When large amounts of CO2 are present, this complex may cause a build up of CO2 and ammonia in the circulating amine. In MEA, ammonia tends to push CO2 into the reboiler, increasing the CO2 residuals and ammonia in the lean amine. In MDEA, the ammonia appears to help drive CO2 overhead, decreasing CO2 and increasing the H2S in the stripper bottoms.

CO2 capture process must be used to control the concentration of this greenhouse gas before being discharged into the atmosphere. Chemical absorption using aqueous amine solution is the most effective technique which has been used for decades for removing CO2 from many industrial sources. This technique is also suitable to reduce CO2 emission from post-combustion power plants. Amine development for the capture of CO2 has been particularly focused on blended amine solution due to its effectiveness in increasing high CO2 loading capacity and decreasing amine degradation, corrosion rate, energy consumption during regeneration, and also the overall operational cost. MDEA, one of the most popular tertiary amine used extensively, has many advantages, such as low energy consumption, low corrosion, high degradation resistance, and good absorption capacity [2]. However, its reaction with CO2 is slow, thus blending with primary and secondary amines, such as monoethanolamine (MEA) and pipe razine (PZ), is essential to increase the CO2 capture reactivity. Diamines, specifically diethylenetriamine (DETA) can also be blended with MDEA to enhance the solvent kinetics and absorption ability as confirmed already in our previous study [3]. Fig. 1 shows the chemical structure of DETA and MDEA

CO2 + NH3 = Ammonium Bicarbamate (occurs in atmospheric pressures @ 0c)

Ammonium Bicarbamate can be formed by the reaction of ammonia NH3 with carbon dioxide CO2, and will slowly decompose to those gases at ordinary temperatures and pressures.

Other things thats could output in theory due to amine treating conditions;

- carbamate ions

- ammonium carbamate

- ammonium carbonate

- ammonium hydroxide

- ammonium bicarbonate

- calcium bicarbonate

- urea

CONCLUDE:

Just seems like the CO2 and Ammonia from sour crude could be combining in the Merox treatment (sweetening process) to create Ammonium Bicarbamate which carries over in combination with the treated caustic soda and is exposed to the output LPG stream. Likely minute(myne-oot) enough that its a non-issue but possibly due to increase of MDEA used to maintain emissions, the problem is compounded and you have trace residuals that are maybe N.D. but noticeable into output?

More LPG makes more H2S which requires more NaOH to treat caustic, which results in larger build up of CO2, which carries over Ammonia and pushes the two compounds combined as Ammonium Bicarbamate into the reboiler which then recirculates into the “lean amine solution” aka lean solvent (clean solvent) which directly contacts the output stream “sweetened” product when set back to treating process.

Fun fact they say the process is called “sweetening” from “sour crude” but you’re removing salts so think of it like your sweetening the product to remove the saltyness.

I still claim nothing, I am not conclusively indicating that THIS is it, but appreciate the opportunity to share my thoughts.