300mm basket if I recall correctly. I could snap some pics of it next time I’m in that quadrant of the warehouse if I remember.

Almost perfect size for a pan of sugar…

Looks like it’s just about ready to ship too… I’ll happily store it for the inevitable future.

oohh look at that beauty 0.0

We’ve got plans for it, and while those plans do always seem to be a month or two out, I know the minute I get rid of it, I’ll be kicking myself for letting it leave.

I’m happy to make an intro to the manufacturer, or another one that I would recommend over the one who produced this one.

Man…you are an AI… you are amazing, love!

so freez material not neccesary

i will be post the machines when i finish

Thanks

Damm this is amazing,. This Have a post procces with clay or carbon? Fresh biomass?

Thanks

Done with very high quality biomass (but cured). No post processing just this method, -20, very gentle rotovapping and then into a vacuum oven while still somewhat solvent laden.

It eventually sugared up, but I don’t have a picture of it in that state.

That’s a nice size for fungal work!

Supreme

So I’m working on a design for a ‘spray wand’ of sorts, for use in this method on a CUP-30 specifically.

i got this idea from someone who didn’t mind sharing or me using it, but the design as stated by this person does not quite work in theory or in practice. looking to get some feedback and to share in the case others want to work one up.

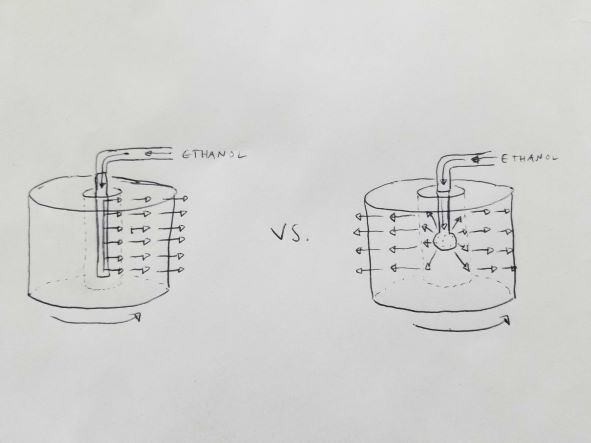

the idea is to improve upon the ethanol distribution of the classic CP spray ball, by taking a length of SS tubing and cutting a slit up the length, so instead of radial EtOH distribution from a point at the center of the spinning biomass bag, we get a ‘blade’ of forceful ethanol, distributing evenly along the interior of the biomass bag top to bottom, with improved ethanol penetration through the interior wall of the biomass bag.

we’ve taken post-extraction biomass samples from the top and bottom of extracted biomass bags and found varying/uneven extraction from top to bottom, so i’m thinking this could help us with that.

though the idea was related as a single long slit, that’s obviously not gonna work as the flow will not come out of this slit evenly–it’ll come out mostly through the bottom end and very little out the top. i confirmed this with a super rough prototype built out of scrap tube i had around.

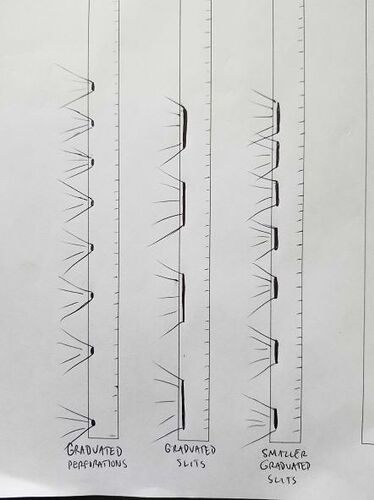

so, i’ve got a few other ideas i figured I’d run past the community. below are some rough sketches of theoretical arrangments for slits or holes, in the interest of getting even flow from top to bottom, preferably in a ‘blade’ spray.

- graduated perforations - this won’t get us the ‘blade’ idea but would better pressurize the wand and hopefully allow even spray from top to bottom. looks somewhat like the ‘nozzle’ style sprayer as pictured towards the beginning of this thread.

- graduated slits - a way to get even spray top to bottom, retaining the ‘blade’ spray.

- smaller graduated slits - same as 2, smaller slits for higher pressure/higher velocity 'blade.

anyone doing anything like this? what say you friends?

I think @cyclopath told me a company once that makes sprayers like this. I can’t recall it’s name.

@cyclopath said you need slots on both sides of the tube to keep the machine balanced. He’s played this game and will probably comment when he isn’t neck deep in projects around the lab.

Doing this type of thing - spray system design - correctly is hard for surprisingly large values of hard.

Simple solution: better sprayball. One that’s 3A certified should have pretty even coverage. Proper placement can be difficult but simplified if you’re able to place it in the central axis.

Less simple solution: Actual spray nozzles.

Very less simple solution - 180° spray ball at the top that sprays sideways and down, 270° spray ball at/near the bottom that sprays sideways and up.

We’ve presently got 6 nozzles inside our 450mm basket fuge. Four dedicated to wash, two to rinse. That’s spray system revision 6 or 7… I stopped counting a while ago.

Spray nozzle selection is somewhat non-trivial - if you use something that shoots a jet stream - which is what your perforations iteration looks like - it’s more likely that you’re going to have a bad time.

You want high coverage, high volume, but low impact.

We are not using donut bags, which makes our lives easier in some ways. Harder in others.

When using donut bags, I would imagine that your material selection could substantially change any number of things, so take all of the above with a big helping of salt.

If I were to be told “here’s a pipe and a dremel and/or death wheel … go make me a spray bar” I’d probably go do a bunch of math that may or may not be useful and end up with something like your “smaller graduated slits” style, but balanced so there’s equal spray along any given outlet slit axis - I personally feel that it’s a good idea to minimize any possible induced imbalance in the high energy spinning death machine that’s filled with drugs and flammable/explosive things.

I’d probably also take the time to use a cone-shaped bit to bevel the outer edges of all of those slits as well.

… @Lincoln20XX has dug deeper down this rabbit hole.

I’ve just learned the hard way that a single (or double) row of graduated perforations is wrong. Because: unbalanced!!

Edit: one issue with the full length spray bar is the size of the hole in your donut needs to be bigger, or you need to insert the spray bar after the lid is closed (that’s how delta used to do it…and may be why the stopped).

most folks successfully using that style sprayer are slurry (or dry) loading into an already spinning basket.

What brand make and model is that fuge ?

Looks huge

Nice

Higher pressure pumping into the spray ball/tube will yield better homogeneity. If spray pressure is 150 psi, the increased pressure of being 1 foot lower is only .433 psi, or ~.3% different than the top. This seems trivial to determine iteratively with a reasonably sized pump and some different size drill bits