I’m a big fan of Matlab myself as well as Fusion Pro, neither is free though but they are quality software that can help do a lot on the data analysis and modeling side.

I should have an excel plugin for DOE somewhere in my files from when I did my lean six sigma, though it’s somewhere hidden in my data archive.

Though it looks like you can do DOE in R fairly easily/cheaply.

yeah and you can use free AWS with templates to do this also.

If you really wanted to anyway… the free AWS is cool - cause you can do like 100 touches per day, but save like gigs of data. So just dump into your database and then do some magic queries a few times a day. tada.

Putting the color aside on this, were you able to confirm complete exclusion of wax and chlorophyll on this run?

We left six 5gal buckets of micella in the -86c freezer and saw zero agglomeration. We recovered the EtOH and ran a potency analysis which showed 86% TAC. It was very glass-like on the surface and broke into chunks.

I’d have to say the method is a success. Final confirmation for us will be a potency analysis of the distillate, and general visual inspection.

Excellent. Then, the next question is, how much warmer can you run while still getting comparable waxlessness/potency?

This is what we are going to find out this week. Since our UPLC is in an unsuitable environment we have to wait for analytics. I have a tendency to not change parameters until I know the full story. So with everything, except distillation, complete we will play with temps.

I’ll post data as I get it.

Did you ever take it to distillation? Did you see any sugar char?

No, no charring. Definitely a polymer-like “bottoms” left in the flask (BR spinning band), which is typical. What’s very strange is our TAC potency on crude was 84-86%, but our distillate is at 87%. We went from 2098g crude to 1400g distillate, so ~600g of mass reduction. Visually the distillate looks typical for the biomass and we don’t do any color remediation.

We suspect, as always, there was an inconsistency in the lab report. The only other thought is that we had isomerization as a result of residence time, but our run was fairly quick. Our vapor temp was 180c and pot temp 220c, which is very typical for our BR. I think total runtime was 4 or 5 hours.

This has been an ongoing issue with us and our distillation. There is always an isomerization to a molecule with a rentention time near CBL and D10. When we short path it isn’t present.

I cant recall all of the details its been a busy week, and then we had an employee test positive for covid on Sat, but not inform us until today. So my brain is mush.

Yeah, I guess I don’t really know about that as i’ve only ever been a film wiper for most of my distillation experience. But this 84-86% potency result on the crude was done with in house analytics, so you are pretty confident in it?

I remember in the early days of distillation, when I worked at Rose City Labs, almost every distillation sample would be hopelessly degraded and could never get above 70-80% TAC (and I mean identified cannabinoids… It was probably 99% with the degradation product thrown in) with three big mystery peaks. Then at a certain point the situation changed and I stopped seeing this as much. I’m not really sure what people were doing wrong and how standard procedures changed, since I never observed this on anything I short pathed – it was very endemic in 2016.

87% acid content is now a standard imo… Meaning your hitting 79-81% decarbed…and how many terps maybe you gave a figure .

From my persspective this is where your distilate might loose its value due to strip of the terps…

This crude should smell and taste 0sm imowith those figures…

Oooo boy!

Box Benkhen here I come!!!

I’m not suggesting you TRY boiling etoh at -80C, I’m suggesting that it can be done, and of one gets carried away with the sucking, and neglects to get their cold trap cold enough, they’ll get their pump drunk…which may not be as much fun as it sounds.

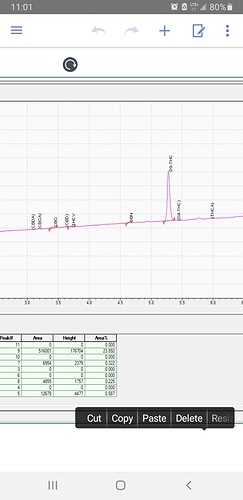

Just wanted to follow up with more detailed data

2016.6g of crude oil with an average concentration of 78.31% D9 was distilled to 1412.9g of distillate with an average potency of 86.85% D9. The distillate has 2% CBG snd 1.5% TCHV.

Body: 1412.9g

H/T: 297.5

Bottoms: 203.5g

Solvents: 100.7g

Crude oil total D9: 1579.1g

Distillate body D9: 1227.5g

Distillate H/T D9: 258.37g

D9 THC missing: 93.3g

With only 93.3g of D9THC “missing” from our oil it is reasonable to conclude our distillation was a success. As the remaining THC is presumably in the bottoms

I reviewed the chromatography and we had mininal isomerization that eluted prior to THCa.

Our hose broke from the cold! So I’m waiting on some SS triclamp to make life easy.

I feel like making thc distillate is a less good idea than making thc-a isolate and decarbing, if purity is what were after.

Yeah and also thca is a more formulate-able product compared to d9. Also 13% more mass before decarb. And still the option to convert to high purity clean d9 if that’s what you need.

seems like the best route!

I agree, in a perfect world I would run hydrocarbon and crash THCa rapidly in reactors. The issues are that our hydrocarbon system is small, I don’t have enough reactors, our demand for d9 oil is about 20kg/month, and the system is dedicated to live resin products. So we will keep trucking with EtOH to play the volume game.

I think that crystalization is a great method for people with technical skills, but ethanol you can copy + paste a million times and train a squirrel to run it. Well… maybe not any squirrel, but a smart one.

Why not just take the crude you produced here and recrystallize in pentane?

Sort of the same reason. I don’t have the tools to scale it well.

Second to that, I’ve not made THCa ‘isolate’ from EtOH crude. I have read through the threads and seen other peoples results, but never really pulled the trigger on attempting it.

If you could spoon me a bit here, how long would that take? Could I reasonably make 4kg/week, or would there be an extended nucleation time. Obviously, I wouldn’t need to go for large crystals, just granular ones, right?

Not certain… @coppertop?