Thank you for this! We will definitely put this knowledge to use when we get back on that horse this week once the weather agrees with us (bad storm) I appreciate the handholding and feedback!

I have actually noticed this on accident. I have been able to pull some wild extracts running a lower amount of solvent through my column, and and recovering with maybe 70% of the solvent I usually use. Then dump a bunch more solvent through the same column, and collect the leftovers for further clean up. It seemed the majority of what I wanted was coming out of the column in the first 70%, and most of what I didnt want was coming in the last 30%…maybe the last 10% sometimes. I have separated these a few times and what I pull on the back end usually smells quite unpleasant…strain dependent…but it’s never something I think I would like to consume.

I am no expert and have no data to support this. Just my personal observations, that may relate to the expert speaking above…

Thought this was started in the winter. ![]() A few of us was snowed in at least, during the worst snow we have seen in the triangle in some years running the house off of a generator, in a flooded basement, running powders.

A few of us was snowed in at least, during the worst snow we have seen in the triangle in some years running the house off of a generator, in a flooded basement, running powders. ![]()

![]()

![]()

![]() Fun times.

Fun times.

Hello all,

I just got my 6’’ indofab CRC in this week and have been having issues removing the color.

My column is packed with 300g Bentonite, 300g T5, 200g MagSil, and 200g Silica.

The product that comes out is much greener than the un-CRC’d product with the same starting materials.

Anyone have some advice on what I might be doing wrong or which media I should try.

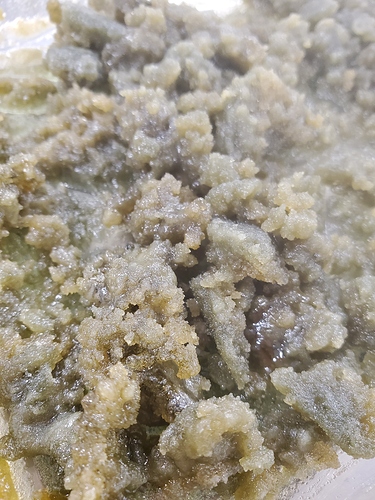

Attached are some pictures of the run.

Did you bake your powders first?

Didn’t read the instructions ![]() How do I know?

How do I know? ![]() Using 2 more powders than necessary.

Using 2 more powders than necessary.

This really ain’t hard.

- Read free instructions.

- Order said powders in the instructions.

- Pour powders into tube.(no walking away @cyclopath)

- Run as instructed.

- Take the white chit out of the collection.

- Post pictures online.

Hi,

Give me a call today, Lets chat and dial in your C.R.C.

@Soxhlet coming in with the customer service

This is why I would spend money with these fine people on this forum. They are here, on the forum, to help…too bad I’m poor as fuck lol.

So soaking media prior to dumping your run is crucial to getting your flow and speeds back up. Also baking media is very important for color.

I know this has all been said before. After our recent experience, I feel the need to repeat this for everyone.

Recently we upgraded our system. From inline filter on 4” column running 5#s at time to rack mounted 2-6”x48” running 15#s at time. After the switch over the filter would get clogged and slow everything down. So after some rereading, we decided to do the presoak. We never had to do this before with the in-line setup.(I’m not sure why) We basically dropped enough gas to see it drop through the filter then close off and open the column to the filter line. After doing this it was a world of difference in flow and speed.

Hope everyone can take from our experience. Thank you all for all you have provided and most of all thank future for creating this forum.

Honestly I’ve had a lot of test results come back from a number of labs that used acetone to clean the testing equipment when I don’t have it in my facility and I used propane exclusively for extractions that touch no powders, for a couple years now. It’s worth looking into that as well, just to cover your bases. What lab produced the acetone results?

I’ve had a couple runs come out with a greenish hue using just t5. Redissolved and ran it thru a fresh column of t5 and it came out peach-ish as expected.

From my experience it seems that the t5 catches lots of blue/greens/grays. T5 also seems to let the lighter compounds come thru first followed by the heavier compounds. I have isolated near pure terpenes using just t5.

It seems like once the T5 has been fully saturated with blue/green pigments it lets the blue/green pigments into the collection which taints the whole solution.

I do not know for sure if this is what is happening but it seems to make sense based off my experience. Any thoughts?

Just like to show off the latest revision on the Chinese boof plate… the support plate design is now changed so it doesn’t look like indofabs. We have had it welded on both sides with a welded top support ring. These should be in sometime late next week. Available in 3”, 4”, and 6” 1 and 5 micron. Price will be similar to the boof filters before it.

You forgot the silica60 ![]()

Run t5 and silica only, and then use more of them.

100g t5

50g silica 60

Per lb of plant matter

Left it out on purpose… T5 works great by itself when used in the right ratio.

I love how all the other stones copied the growth structure of the seed stone.

Super square or diamond shapes that pristine lines. Perfect cornering

Is that for outdoor or indoor?

150g per lb of material sounds like a lot…

I’ve heard of people using 30-40g per lb of material. Has anyone tried this amount before and had good success?

It’s really not a lot. If you’re shooting for white. That’s what it takes.

I’m running indoor

I use 30g a run in a 1.5*12 spool.

I think people are using up to a 2:1 ratio of powders to expected oil.

If your running a # and expect a 20% return, that’s 90g, so 150g of powders is close to 2:1.

Got a procedural question. When using a dry ice passive setup with Nitrogen. Is the nitrogen used to push the solvent from the material column intinthe collection pot in a cyclic fashion with burping.

Or just at the end of the cycle to move the remaining solvent?

In other words, should the solvent still be able to flow through the powders durring most of the run with out nitrogen assistance?

I’ve searched but havent come across this scenario. Only blockages and how to set up the N2 push.