Ever tryied without magnesol it takes a good part of your yield !!!

How are you packing the powders?

I can attest to this as well. I see it in tests where I work now - We don’t carry acetone anywhere on property. It has also happened plenty at home over the past 3 years. Lab director always said it tends to come through on tests regularly. Almost always with fresh frozen biomass

Three filters on bottom of colum t5 on bottom then magnesol in the middle and silica 60 on top I I haven’t packed with a press yet tried individually packing by hand then a ring and filter on top to keep powders in place

I am not getting any particles threw filter just feel like I am not getting any contact with any of the medias

Hey guys I’m curious if anyone has experienced where the finished product has a a burnt rubber or a wet sock sort of flavour? I’ve been using a meticulously placed and order taped BVV sintered plate and have been fearful of contamination passing through but the dissolved test showed nothing of the sort. Only variable we’ve changed is we switched to warm runs. Using T5 and s60 and AA in a 40/30/30 mixture.

I feel it’s the source material and probably sulphur burners in the rooms to avoid bugs/mould but I just don’t know.

It’s all one persons material I’ve been doing piece work for for a while and they’re pissed.

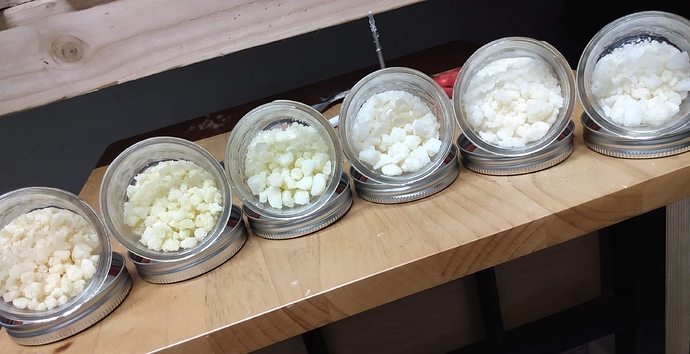

Final products look like this (from trim)

My clients said the other day that I made his poop soup smell like dirty feet! ![]()

![]()

![]()

![]()

![]()

![]()

![]()

Lol maybe he did smell dirty feet “CRC” lemon funk what I get idk

try pulling a vaccum through the column while you add the powders, like loading a buchner funnel.

Could I do this inline below a 3 x 18 column? or is it better to have it go from material column to a secondary column for remediation? Since im running at most a lb most of the crc available are much bigger than what im thinking ill be needing. Appreciate the info!!

Fats are colorless when isolated so you have to recover your yield in cuts like a distillation. Begin by isolating the last 20% of your recovery and seeing if that removes the rubber taste…then reduce that cut until you learn where fats are chasing yield.

@murphymurri has figured this out pretty well.

I’ve seen ppl do this…add couple filter plates and preferably a welded disk last. I use cheap ass 6" spool

I’ve run crc like this, works just fine.

Definitely will try this, my set up is rack mounted and I have a ball valve on the bottom to pour out directly into jars, so that should be easy to handle. Thank you!

Pulling fractions is they key to success. Without fractions you’ll have purified trash getting through , which is much worse smelling/tasting than the previously diluted version of the oil you put through the column.

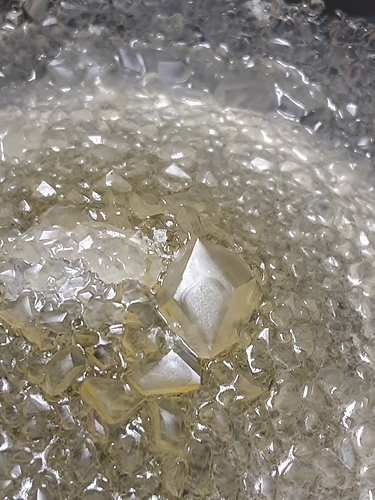

16hrs after seeding. Dont get me wrong. I fiddle fucked around with this jar for 3 fucking days trying someone else’s tech that was suggested to me. Absolutely nothing, literally. So. Went back to square one with my mother liquor and ran my tek. Dropped seeds that evening and came back the next day to this beauty. It wasn’t even done yet. I was so excited to see the one in the middle because it was a choice seed. It’s the same fucking crystal. But like 20x bigger lol. So I poured it off for second crash in a smaller jar just to gawk at that beauty. I didn’t seed before. Eeeeek. I know. I didn’t have any at first or would forget to save some or forget to add em lol. Cleaning this whole jar just for seed stock.

Wich fraqtion is the worst smelling/tasting in your opinion ?

@murphymurri

I imagine a tower of collection pots with ball valves in between for small scale fraqtion collection or yust seperate collectiontanks for large scale

How have you solved this ??

Curious as to how you’ve managed to separate and identify these different fractions. I’m just trying to understand how and why it’s now becoming an issue that wasn’t coming up before for us back in the spring/summer during the infancy of our crc trials and testing

Harry,

You dont have to identify the fractions in advance. It is fairly common in chromatography for fractions to be colorless which means you identify them after the fact, generally via analytical testing. In the case of using butane/propane, you’ll be able to evaluate the visually within a few hours based on color as well as precipitation of solids (thca, waxes etc). My goal is to pull fractions that are substantially different from each other, with minimal overlap of undesirables. I can always combine similar fractions later, or re-run muddy fractions to purify. I love chromatography because you can always get the results you want if you’re willing to put in the work. ![]()

Also, one reason why it may not have affected you before was if you were not rinsing the column sufficiently. It stands to reason that some of the stinky stuff like sulfur which is polar wouldn’t come out until the final fractions, which means you could avoid it simply by sacrificing some of your yield and cutting off your run early. It is not too uncommon for people to get poor flavor when they increase their yield - but this is easily resolved by collecting fractions.