Ahead of our time yet again - here we have the ProJak Propane Rated Centrifuge!

Setup as a Hot Tank - Cold Tank - Centrifuge Isolation Station, it is the most efficient method of collecting and purifying your acidic cannabinoid isolate.

Isolation at any scale!

Question is, how much isolate does your lab need to produce?

- 25 Liters: Rocking Miner & Mini-GD2

- 100 Liters: Rotary Cannabinoid Miner

- 40 Liters: WFE Crystallizer

- 200 Liters: Propane Centrifuge Isolation System

Designed for labs of all sizes we have the only scalable solution to bulk acidic cannabinoid isolation since 2020. Eliminate limitations that come with costly heaters and chillers with short life spans and constant maintenance.

Illuminate Your Lab today and take advantage of our patent pending ProJak Refrigeration Technology - the biggest thing in extraction since closing the loop! Providing +50c to below -50c on demand heating and cooling within minutes anywhere on the system while removing the need for power hungry water heaters and chillers!

Call us at (970) 893-4612 (9-5 MST) or contact Sales@IlluminatedExtractors.com for more information.

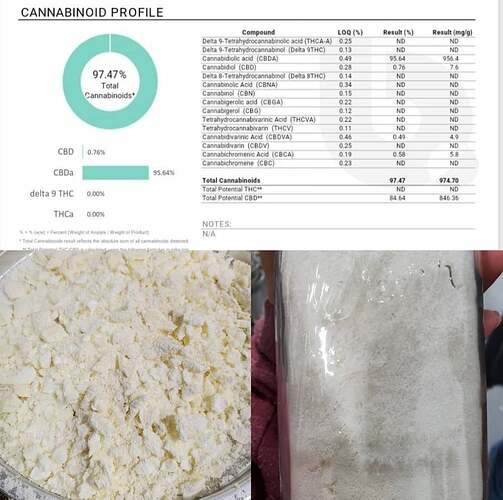

100 Liter CBDa isolation (2021):

https://www.instagram.com/p/CUAlwpgAo01/