Whelp I certainly do lol didn’t realize we were talking about two units. I’m just gonna leave my little SSR protip here and butt out

Sorry, I thought I didn’t ask this question so I repeated it twice. I wanted to delete the second receipt but don’t know how to delete it.

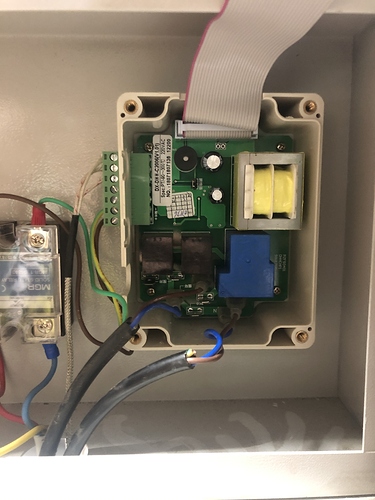

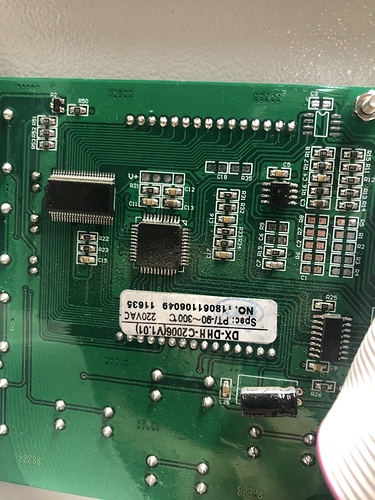

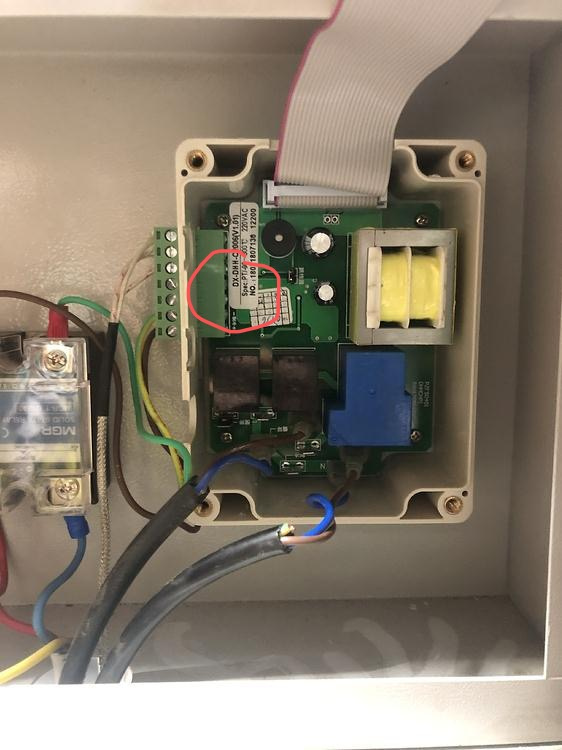

I can get into the settings on the unit pretty easily and I have the Chinese manual but there are no options for activating the heat option, looking closer at the pcb I believe it was a universal controller that never had the components added for the heat option as there are a lot of empty spots on the board.

My hope is there is a deeper setting/configuration option I cannot access without the right key combo.

I think you’re correct about the missing components and are looking at a new PID to make this work.

Can you take a clear pic? I want to see the parts in the red ring.

It looks like it has heated components but I need detailed photos to confirm

Edit: Didn’t look closely enough. Oops.

I zoomed it in. Hopefully that helps.

Yes, this controller has heating component.

What you need are 2 points.

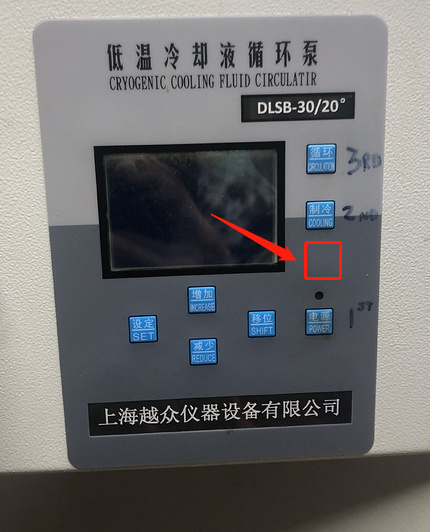

- Check if there is a Heat button on the controller. See the pic attached. (some manufacturer may remove the heat button)

- Add a solid state relay to control your heating coils.

@EffisonAndy thanks for the reply, there is no button there so I’ll have to add a secondary PID.

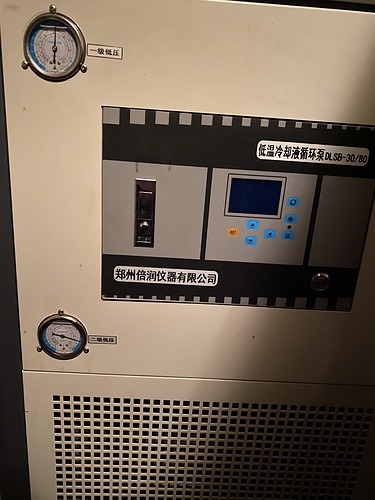

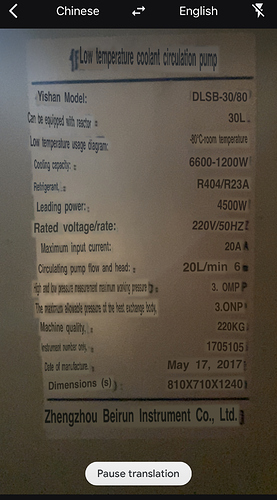

We have a dlsb 30/80 that turns on and starts chilling down to about -17 c then once we start recovering from the roto it warms back up to room temperature. I’m thinking refrigerant leak. Any pointers on charging the refrigerant or where to get R404 or R23A?

R404a you can buy off eBay. R23 is a bit tougher. You’ll want to recover your refrigerant through a filter drier if you suspect you had a leak. Then pressure test with N2 at about 50 psi below the HPC setting. If it doesn’t leak, pull vacuum to about 100 micron and hold for 1 hour. If it doesn’t get above 500 micron you are good. You may need to repeat the vacuum cycle to dry the system if there are volatiles present. Do not vacuum test if you have a leak because you will pull moisture into the system. It is important to leak test under vacuum for these systems because they do get under atmospheric pressure and many seals are not designed to seal well under vacuum

You are welcomed

First: Your chiller can only cool down at -17C, I think the second compressor doesnt work or like you said refrigerant leak. Any video is helpful to check where is the problem from.

I dont think a -80C chiller is good to cool the condenser of a rotary evaporator. -30C chiller is enough, you dont need a very low temp, what you need is the big cooling cooling capacity at -10C to -20C, the big cooling capacity can take away the heat. You know -40C or -80C need a thinner capillary which means the cooling capacity at -20C or -30C is very small. BTW, what is the capacity of your rotovap?

Thanks for the response I’ll get Her opened up and shoot a video of the issue.

It’s a dlsb -30/80 (-30c up to 80 c) running a 30L roto at the moment.

I see, the chiller is a -30C not a -80C one , right? If it is a -30C chiller you dont need R23, just R404 is ok. Show me the spec label if possible.

I will have to open her up later this afternoon got some work to do in the garden

Hey @EffisonAndy, tell your boy @AlvinZhang we only need one rep from your company here on the forum please? We don’t like getting spammed from multiple reps.

Got it. No problem.

Man, It is a -80C chiller. Two 3P compressors system. Let’s open it to check the electric box and compressor spec.