Careful packing kief. Mix it with flower material or something.

Bvv powders gave me all kinds of white residue. Destroyed yeild too. Was fun to experiment with though. T5, t41, Celite 545

Tip the day. Put a filter plate on the bottom of your material column w gasket no screen, pack directly on top of it. Then you can pack as tight as you want and in the end your not struggle to get that cap off fast and gasket on before it starts growing out of it

Toss that over in tricks of the trade thread. Such a simple solution I’ve never thought of

Using a qtip to get at the rim of the triclamp spool to make sure there’s no biomass where the gasket goes is a good trick as well.

yes I use a thooth brush for that

find particals in the weirdest places you think all is spotless clean and bam some little speck off something right there in the rim pfff

We change out 3 material column spools + filter plates and keep them on dry ice, packed prior to runs. Seems to be more helpful in yield.

Please elaborate on these “tube inserts”.

Did you make them or are they available for $$?

They are stainless steel chimney tubes in metric sizes

Since beeing in europe they are easy to find not sure about sourcing them in US

I 3D printed an end and put it on a PVC tube for packing tubes. I prepack my tubes and put them in a lab freezer at -76C before runs. I also freeze my material before packing and just throw bags on the ground to break up buds. I never grind and do not use CRC and everything comes out nice and light.

love the idea of freezing the material column to -70 prior to the blast. we have been dry ice freezing cured buds/trim then packing & blasting tightly. the extract has been darker and i assume it’s the moisture from ‘melting’ post deep freeze. maybe we could just use the dewar column as the material column instead and slurry dry ice the jacket.

Are you using fresh frozen or cured bud/trim w/ your method? and how cold is your tane?

I run both. 1st pic is Somango shatter from a dried cured run and 2nd pic is from fresh frozen Maui Wowie. I throw all my tanks in the deep freezer about 3-4hrs before the run.

My 3x36 material column and dewax column stay icy frozen through all the runs. I have a 4x48 sleeved dewax column and run dry ice alcohol slurry in that and my wart cooler. I have to run nitro for pressure.

Would keeping pre-packed socks in a freezer or in a room with a dehumidifier be more effective?

I was told grinding would effect the overall color, yield, and consistency of the end-product, if you CRC does any of this matter?

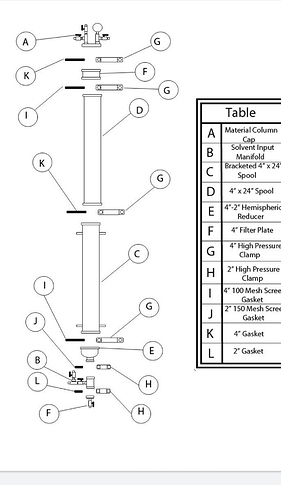

What micron filter do you guys use on your material columns? I had a blowout on mine recently trying to blast column that was too tightly packed I guess. I have a 6" going to a 3" and I think the micron size of the screen/gasket (it’s an ETS machine) is like 50micron?

why not just make a run in the freezer lol

thanks for the info.

Are you doing a passive or active system? we stopped dewaxing due to clogs. we were not doing 10:1 ratio like we should of though.

That’s pretty cool.

Do you think there is any benefits in going smaller micron for the screen gaskets?

I ordered 6" and 3": 150, 100, and 5

I run a lot of kief so I’m trying to catch it prior to CRC