I’m running into an issue with my butane getting stuck in my material column and I am losing like 1-2 lbs each run. How do I get as much possible into the collection pot? Nitrogen push at the top of the material column doesn’t seem to be effective. If I circulate cold alcohol through my base would that make it easier?

Recover the butane during recovery.

Put a “t” from the top of your material column, run that line to a “t” on your sieve. Boom.

I’m recovering the butane but like I said, there is still 1-2lbs stuck in the column. I’m running -80 extraction solvent and after I break down my system there’s still hella butane in the column

Pipe you recovery line to the top of your column with a t and another hose.

Youll never get it all in a timely manner without heating your columns. Jacketed columns ftw

Gotta heat the column and recover

i have the same problem did you ever worck it out???

The answer is in the responses above

Quick Tip: When using the jacketed columns to recover, the solvent will try to hide in the bottom of the spool. If you have a spherical reducer as your bottom it will be obvious how much is still hanging out in that section from the condensation formed on its surface. Get a flat bottom reducer to prevent this or a jacketed reducer to ensure you recover all your solvent

Silicone heat tape or silicone heat mats wrapped around column will get most of the solvent out quickly

I have had good results opening my valve to collection during recovery (once collection has reached a vacuum) this seems to clear out the filter stack of butane. Then I recover from the material at the very end of my run.

This won’t really work with a crc column inline though…

Build a tee manifold to reroute your hot water through the column jacket. You only really need about 5 mins of constant heat applied on the jacket. Then you can reroute back to your recovery pot after to finish up the run.

What if the butane at the bottom of the material column is cannabinoid rich and you aren’t content to simply recover the gas? Any suggestions on how to get the last bit out of the material column and further down the production stream? N2 available, and CRC in line after jacketed material column.

Run more butane.

Hitting the column with n2 helps a little, but there is always some butane left in the material.

We just keep the lines open between the material columns and the collection pot while having the recovery line open with no heat applied. During this time we are chilling our second tube while we watch the remaining drops finish dripping. Usually they are finishing around the time the 2nd tube is ready to go. We also push with nitrogen. Also I find as you bleed your nitrogen out of your solvent tank it speeds flow up a little.

This works if you aren’t running an in-line crc. But with a crc in-line it won’t really help.

Once I’ve recovered to -15" Hg, I valve off the columns and recover them separately, while simultaneously heating them to 150F with hot water through their jackets. At -22" Hg recovery, I switch to high vacuum pump and pull to -29.5, before backfilling with N2. I then pull -29.5 HG a second time and again backfill with N2. The material will contain less than 1% LEL.

a recovery pump will get most of it out but you will never get it all out

Would love to see some pictures of your set up sir.

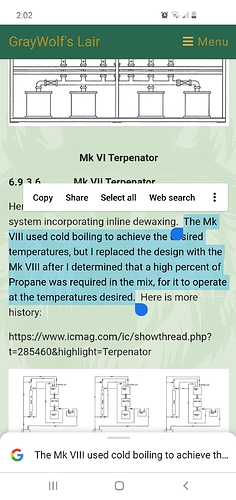

I built a number of renditions, but this link gives a good overview: