Southwest Florida

I am willing to do whatever we need. If we can avoid a $5,000 fume hood and not risk our use of the space.

i did a few posts up

He can’t use ozone because he can’t vent to the outside.

@ajonesy777 your best bet is to move. You may be able to search around above the ceiling for a vent to the outside but I doubt you will find one.

If you do happen to encounter a vent, you will still need to modify it. It sounds like you need to do your extraction offsite and then strip the terps. After you strip the terps you can add the leftover extract into your oil and mix at your location.

It sounds ghetto but this way you can run out your lease worry free, and then go back to extracting with oil. You will see higher yields and its honestly gonna be a better product anyway.

Hydroxyls are safe. I know this link is older but the info is sound and so is the tek. I love it it’s been very helpful in most areas of cannabis.

I am not sure that we are able to find a space which provides us the same value. What types of spaces can I look for exactly? There are no “lab spaces” to rent in my area and a warehouse would require substancial buildout I would imagine. My main problem is actually the smells from making topical products, essential oils, menthol, cocoa butter etc.

I was thinking more along these lines, this would help solve your problem of not reaching a high enough temperatures in your pressure cooker. It would increase the rate of heat transfer to your extract and make an overall improvement on your process.

Have you toyed with the idea of building a container specifically to mix your product formulations in?

Right now you’re mixing in the essential oils by hand in a container that’s open to the atmosphere, right?

We hired someone to build this, it took him over 3 months and cost us over $1,000 with filter

It does not work as it was not built clean enough and there is too many areas where air can flow through.

I hired a contractor to finish the job and he is extremely bad news. Is a criminal psychopath who robbed us for $1,000. I did not vet him well enough and he has a serious record and history of violence. Has made many threats against us so we are leaving it there.

I don’t want to hire a third person to work on this thing anymore as it has been a horrific journey.

I either need a fume hood or an industrial air filter I believe at this point, some have recommended hydroxyl filters.

This is exactly what we need, can you provide a link?

I understand you hired someone to build that, I’m not talking about an enclosure I’m talking about an enclosed mixing rig with triclamp connections. You could get a ferro fluid sealed stirring setup to mix you’re products (salves, lotions, etc.) up without any leaks to the atmosphere.

It will probably cost you the same as a good fume hood tho.

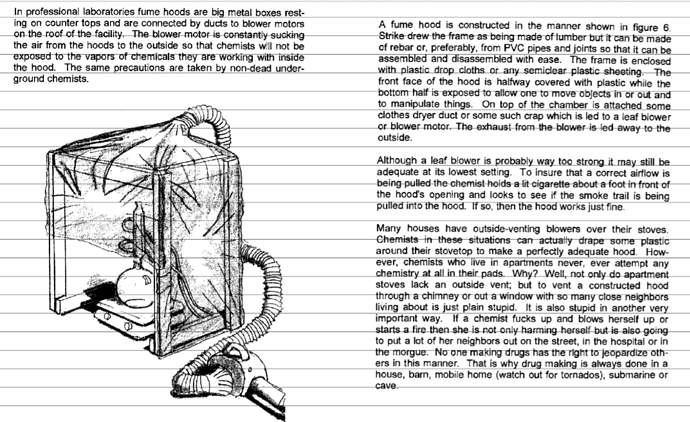

Go with STRIKE’S ghetto tek and build one using PVC, plastic sheeting and a powerful inline fan.

I would modify the design and build a sliding plexiglass door.

That sounds incredible, but having difficulty visualizing it.

Yes, it doesnt sound like hes working with much product I doubt OP is going to fill the diamond miner up. As long as you don’t load a shit ton of extract in it at a time it will function sufficiently as a decarb vessel.

Hes using an electric stovetop to heat with, the flat bottom of the diamond miner will work fine.

@BG305

try a 12" spool with lid, you can stir with a magnetic stir plate through the stainless vessel. Make sure you allow the vessel to cool like @ScoobyDoobie suggested so you don’t have volatile aromas escaping.

Make sure you only open the cooled vessel inside the hood with the carbon scrubber pulling the air from the hood.

lastly you may want to find a way to store the waste biomass from the process, I imagine that stinks as well.

Have you considered formulating the topical with isolates?

If you have complaints tell them that they are smelling essential oils lol!

I was going to suggest a mag stirrer too but seeing as the products he intends to mix are very thick a mag stirrer may not work very well. Also trying to use a mag stirrer thru stainless steel may induce eddy currents and heat up the steel rather than allowing the magnetic field to pass thru it and spin the magnet.

what about something like this with the formulation in a reactor? Run a long reflux condenser on the lid.

https://www.aceglass.com/html/3dissues/Mechanical_Seal_Bearing/MechanicalSealStirrerBearing.pdf