Does anyone have an idea as to how I can vac down my system without the cmep yellow error light coming in every time? It’s annoying…i can’t build pressure and suck at the same time obviously so I don’t know what the F to do.

Are you using the cmep to pull the initial vac on your system?

You dont use the cmep to vac your system down.

Its for solvent recovery.

Get a cheao rotary vane pump

Pulling hard vacuum on the CMEP variant pumps is going to kill your top end seals and bearings much quicker than if you follow @Slabby’s advice and use a (much cheaper) vacuum pump to pull your initial vacuum before you introduce solvent to the system

No I’m not using the cmep to vac down my system.

You need to explain the issue better then because i dont understand

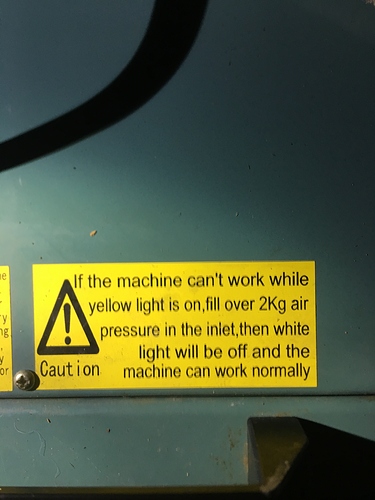

So the issue is every time I go to vac my shit down this stupid fucking yellow light comes on… I am unable to vac my system down with this pump…unless someone has the answersssssss

So your vaccing down your system and this light turns on indicating what?

Is it saying it wont start under vac?

Have you used the pump before?

Could it be it just needs butane in there to operate? So pressure comes from collection pot?

I have never used the cmep 6000 so im trying to just help at this point by bouncing ideas

Indicating it won’t start. Yes I’m assuming it needs pressure to run…just don’t know how to get pressure build up and a full system vac at the same time… I tried closing the valve and then power up but as soon as I open the valve the yellow lights comes on…

I assume you would pull full vac. Yellow light.

Then you blast and have solvent in your collection = pressure. Open valves. Fill pump with pressure.

Ok but I need my pump sucking my solvent through my columns…

Can you post a pic of your setup. Have you ran this setup with this pump?

Is that a 6x48 material column? Hard to tell

Yes it is

Why do you need your pump to suck the solvent through your column? I run 6x48s and can get atleast 1/3 of the solvent into collection before i do a hot looping

I don’t know. I’ve always had my pump running when I start filling my column

Its not needed. Do you run cold? And if so how?

Start warm and have two 60’ coils cooking my tank

So if i understand your solvent is warm and travels through 2 coils before the column? Do you have problems with filling the column and it getting stuck?

If your coil has valves … Once your done injecting take the coil out of the slurry. Close the valve on the backside going to your tank and open the one going to your column. Put coil in hot water. Itll create a vapor push and dump atleast half the solvent out of the tube. And then your pump can get pressure. And you can turn it on for the hot loop or have it turned on the way you normally run