Good evening guys! I hope all is well. I have a question about a Ext 420Haskel pump. Is the Haskel suppose to compress the butane gas back into a liquid when going back into the solvent tank during recovery? I’ve noticed my solvent recovery line from pump to solvent tank is warm and my chiller temp going up from -20 to about 10 degrees due to the hot gas being put back into the solvent tank therefore driving pressure up in the tank. Has anyone experienced this? Is the pump malfunctioning or am I doing something wrong? Thanks a bunch guys!

The pump (usually) draws in vapor and compresses it. It may condense into a liquid in the pump but usually does not. The higher pressure gas does condense at a higher temperature though, so as long as the latent heat is removed, it will condense the vapor into a liquid. Does that help with your question?

I think it answers it. I think the latent heat is removed. I have a chiller filled with IPA that feeds my solvent recovery tank to chill the tank to -20 to -30. But as recovery goes on the temp of the IPA/chiller is reduced as gas is being recovered back into the tank.

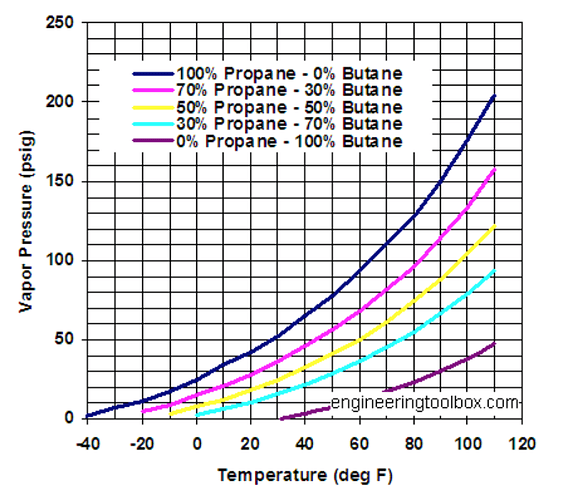

Will the gas condense back into a liquid overnight after recovery process is done? I have my chiller running 24/7 to keep the tank cooled. I notice that my pressure gauge reads at about 25-30 psi on my recovery tank even after sitting a day at -20.

what solvent are you using?

if you’re using straight butane and have pressure at -20C you’ve got air in your system.

I am using straight butane. How am I getting air into the system? I vacuum down my columns down to negative pressure. So i don’t know where air would be coming from.

leaks happen. if your recovery pump is pulling your receiver below 15PSI, there is a pressure differential that would allow air to enter (also requires a leak). the lower you pull your receiver with the pump, the more likely you are to pull air in (only if it’s leaking).

how long to you hold after achieving vac?

do you vac the collection down too?

How long have you had that pressure in your tank of a morning?

at -20C, you can vent all the excess pressure from your system. there should be very little butane in the head space of your tank, but you should still route it outdoors and treat it as if it was flammable.

understanding your solvent is important…

you can also take (most of) the heat off your solvent between your pump and tank using a coil in a bucket of water if you’d like to be able to run again with less waiting for your solvent to cool off.

“ if your recovery pump is pulling your receiver below 15PSI” by receiver do you mean collection pot?

I hold a vacuum on my columns for about 10 minutes before I start running the columns.

I don’t vacuum down my collection pot which would lead me to believe that is where my air is coming from and therefore being put into the solvent tank?

I’ve been doing an extraction during the day. After I am done extracting and recovery, I’ve noticed that my solvent tank is reading at roughly 15-20psi. I thought this 15-20psi pressure in the solvent tank was a result of the butane gas during recovery building up pressure but I am wrong I think.

I come back the next morning and there is still pressure in my tank even after bathing in -20c IPA chiller overnight.

ding ding ding!

and yes, “receiver” == “collection pot” (at least in my whirled).

got that.

the question was “how long has this been true?”

or rephrased “you’ve been sucking air in there every time you run…have you noticed the pressure in the tank of a morning increasing gradually over time?”

Your chiller that cools the compressed gas coming out of your pump is undersized.

Edit: Place a dry ice coil between pump outlet and solvent tank and you’ll address this issue pretty easily / cheaply. Better option is to place a heat exchanger hooked up to an appropriately sized chiller.

sure, but that is no excuse for pressure with n-tane at -20C the next morning…

I am going to start vacuuming down my collection pot/receiver. If I am still getting pressure in my solvent tank even after vacuuming down the collection and when I am done with recovery, then it’s safe to say that there is a leak somewhere drawing air into the system correct???

Thank you sooo much for your help. You’re a blessing in disguise. I really appreciate it.

chill solvent tank to -20C.

Vent safely.

you almost certainly don’t have a leak.

you have been “recovering” atmosphere into your solvent tank.

edit: what disguise am I wearing this time?!?

Yes I have noticed it start to increase.

I think there’s a few possible explanations:

- The chiller temperature indicator is off (as often is the case with DSLB or other China chillers)

- The jacket temperature may be -20C, but the solvent is not reaching that temperature

- Nitrogen gas?

I don’t use Nitrgen for assist.

I think explanation #2 could be a possible answer as well.