Leaving the lid off while heating? Trying to get rid off all the terps? That’s hilarious you would want to heat for multiple days not under pressure.

Dude most carts aren’t made for the viscosity rosin brings to the table - period. That alone isn’t in their operating specifications. Get the fuck off the high horse. If you’re THIS educated on the matter you should know this is something they ask about all the time and CONSTANTLY ask for feedback about. And the only reason I can say this is that i’ve been a guy giving consistent feedback to salespeople who’ve given me samples to give a shot with rosin. Not THE guy by any stretch of the imagination - but A guy that’s been asked.

But if you knew better than the rest of us you wouldn’t be asking this question.

See also where I said

Read.

Totally correct, the one strain that I couldn’t get bubbles out of I did have to heat gun the carts at around 140F to remove the bubbles. And since bubbles create more surface area this is a pain in the ass as you have to fill it up, blow dry it and then add more to it. This guy seems like he has all the answers and doesn’t want to take any advice. And he’s saying that heat gun your carts removes warranty? What the difference between filling them with 150F rosin compared to heat gunning it at the same temp? Makes nooooo sense.

Or furthermore raising the fluid path temperature to a point where it’s not creating bubbles - will that void it too? How do they tell the difference between material too loose (aka super terped disty) and something like overheated rosin that gets much runnier than intended and soaks through. What then? Do they run analysis on the cart? When we were getting giant 10k+ (D8, so a bit higher viscosity than disty) runs of carts done for distribution we’d just simply test them and tell the manufacturer “Ok XXX amount of carts shit the bed” and they’d never give us 20 questions. Just say ‘Oh ok, the next shipment will have that covered’. It’s not like we could send the carts back to China for them to QC.

This thread deserves a skypenis.

Lolol.

Please just read this.

If you are leaving gas in the solution that bubbles.

You have to heat with a heat gun, wait for it to go down and load more:rofl:![]()

Please tell me this is production friendly in anyway shape or form.

I’ve been working with alot of cart manufacturers lately, not one has recommended hitting their hardware with a heat gun and from my own R&D this can cause was more issues than solving it before you load it. Which is what I explained.

It’s a very simple solution that doesn’t require a bunch of extra equipment and makes it 100% ready to go even in an auto injection type machine not hand filled as you guys seem to be.

If someone offers a better solution, great, if a worse one, ill def point out how it’s worse.

Read above lol.

Rosin is way more variable than d8, it’s hilarious to compare the 2.

Anything you can add terpenes to at the end is obviously going to have a much different method. This is tried and true with some of the biggest manufacturers in the US. They certainly aren’t sitting around with hair driers filling each cart a couple times. They want a reliable fill level without extra steps

No doubt I understand that your looking for a consistent SOP but there never will be one with rosin. Just my 2 cents. I actually gave you a really good method on keeping things consistent with the LS550 and the table top convection oven. And you’d be surprised how many big brands re introduce rosin HTE or cdt to keep it from crashing. All depends on the strain and quality.

I like that people try to use a centrifuge. Issues is, biggest person doing this is Tony V and his products are not reportedly better than not doing this, you are incurring loss, and adding in costly equipment. I do think it should be explored.

If adding in terpenes to change viscosity and try to improve taste, sure, some of this could be done a different way. But for live rosin correctly labeled(IMO you should label introduced terpenes(usually not hash rosin based)) which would make it not longer exactly a live rosin product.

This is just for live rosin without added terpenes or additives to change viscosity.

And you don’t want the solution under vacuum ever when heated if working with just the original terpenes.

That stuff is very applicable and can improve BHO type as I often would just decarb THC when I used to make BHO pens and reintroduce the sauce. This does improve quality vs method used with rosin.

However this is not being done successfully from anyone I’ve seen using straight live rosin.

The best product is just extremely high quality live rosin with very little manipulation.

Only opening lid to stir and putting it back on(you don’t need to wait for bubbles to be gone, just more shouldn’t form when continuing to stir) will give you great terpenes retention and can easily be done with just a dab tool and no other extra equipment.

And yes, when writing SOPs for live rosin you need to add in variance and there is not a standard that works for every situation. That’s why being able to see the solution and not having it in a diamond miner is needed as you can see when done visually but I can’t tell you it takes x amount of time or stirring, but I can tell you it will take 3-8 days or you should used between 150-180 as that should cover the low and high end of it.

I add on these variances and what visual cues to look for when writing the SOP so that way it can cover the process regardless of variance.

I also add in some testing before using and write up a test batch SOP to determine if live rosin solution is viable for production.

You need to learn how to read, d00d. And remember what you wrote, yourself.

These two quotes are the same thing, with different words.

Terpenes will absolutely escape with the C02.

You said it, not me. I said the same exact thing you did. Stop trying to be Mr smart guy, you’re not it.

Holy shit… just take the oil and centrifuge it with no screen or filter. How hard is this to conceive? Gas will rise easier under more gravitational force. There will be a separation of solids and liquid. The gas bubbles will disappear. You want a solution to get rid of bubbles before carting? This is it.

This if after initial heating which you definitely didnt specify. Lol read the whole thing… you just say to leave lid off, not during only removal of bubbles.

A 2 hour process, vs 3 days at 180 which is what it sounds like you are telling people to do with leaving the lid off while heating, you didn’t specify after initial heat, you just said heat. Science should be specific.

During initial heat you leave lid on and don’t let terps escape.

So if I already listed this as an option, why are you coming here and saying it again after letting me know you do “science” lol.

Also most people will need the last 2 options of using a tool and closing again which has the least amount of time that the solution will be open for to the air.

So congratulations you very poorly offered a solution that was already offered that is the least effect of the 4 listed. Great job science bro.

Would like to see this ultized and how effective it is verse what is listed to see if cost of equipment would be worth it.

We see alot of people saying centrifuge in theory of solventless but not in application.

Send me 2 kilos of bubbly AAA rosin and 4000 .5g carts. I’ll send you back 2500 perfect carts, an SOP, and links to the centrifuge needed. Deal?

You’re overthinking this. Just vac it out lol.

Cool story, bro

You are right and everyone else is wrong. The catch all solution is having an on site wook to work magical carting spells on your rosin. These guys solutions are just distractions from the truth that the industry doesn’t want you to know

I have 2 solutions to removing co2 bubbles and maintaining terp retention during live rosin decarb.

#1. a very simple, quick and easy yet generally overlooked solution that creates a unique product every time

And

#2. an in depth solution that takes time and labor but creates consistency

But as I’ve said before and I’ll say again…it’s gonna cost you ![]() @MikeyHiH

@MikeyHiH

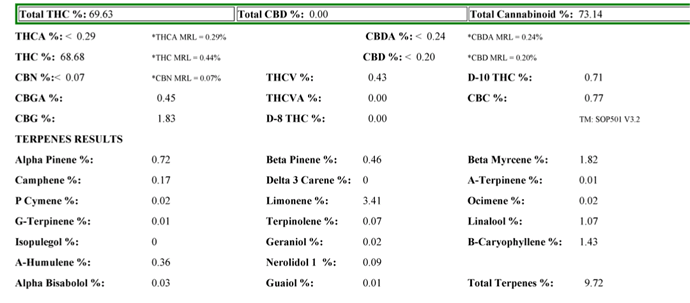

@MikeyHiH I would love to see some pictures of your carts! These still tested almost 10% terps and Under 0.26% thca. Never used a heat gun, did not mechanically separate, sealed tight in jar, never reached above 200°F and bubbles are removed prior to filling.

The point here is that others can achieve the same end result without doing the EXACT same method. You seem to have a good amount of knowledge not only in the process,but in organization of the logistics of documenting this process. This is a very important tool to have, however it is almost all useless if you aren’t willing to learn from others, and that is what I see here. This is,in my opinion, the BIGGEST issue in this Industry right now. I understand confidence is needed in any operating procedure, but overconfidence has destroyed so much more willingness to learn that I would rather be uncertain and change my “SOPs” all the time then follow these step by step instructions only to be surprised one day when you are too far behind everyone else, because you weren’t willing or able to learn from others.

Does that mean that my product is inferior to another product because it has bubbles?

This ![]() The ability to change your mind and never be confined to the constraints of your convictions is a masterful skill

The ability to change your mind and never be confined to the constraints of your convictions is a masterful skill