Hi everybody,

We are looking for a smart way to dry our hemp flowers and leaves pretty fast without boiling our cannabinoids. So far, we found a vacuum/microwave solution at two vendors in Canada. Does anyone know vendors in the US selling vacuum/microwave solutions or does anyone know about other technologies to get the described task done in due time?

Thanks for your kind support!

That’s how they dry planks of hardy board that’s been painted.

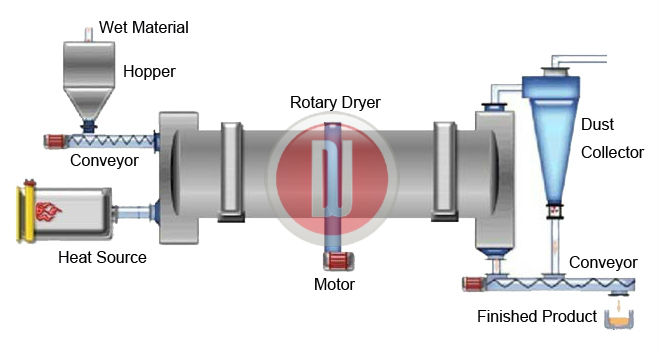

They also use rotary drum dryers for hay/grasses

This is hemp: (I’ll have to have my CO friends send photos of theirs, it looks similar to this)

4 Likes

Thanks for your info provided. I will look into it.

I wonder how they clean that beast or if it gets sticky and clogged with resin. I’m looking for a good way to remove all moisture before extraction but all the rotary and flash dryers I am looking at seem way too big for what I need.

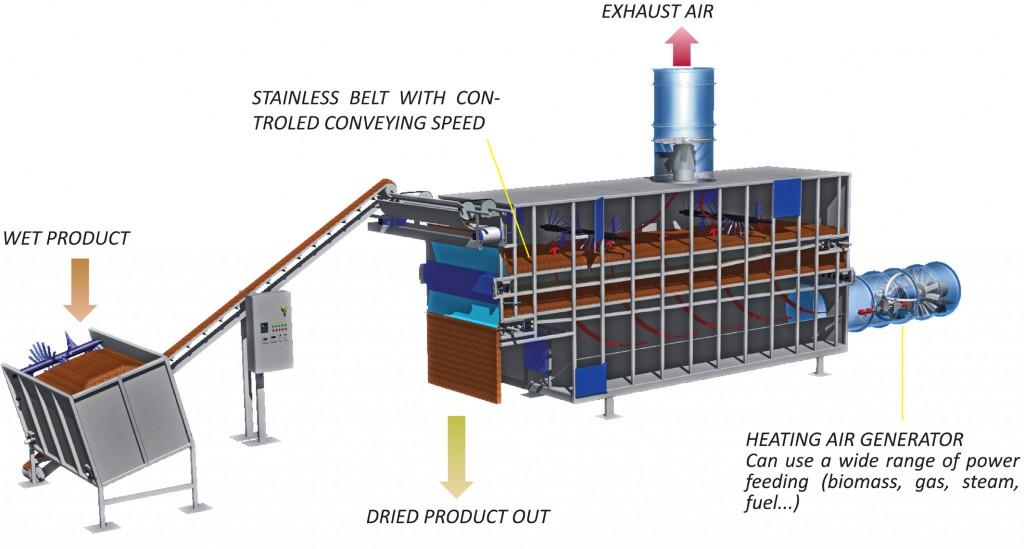

IEC is using a flash dryer, which dries using a high temp, high bypass air for a short contact time. We know terps can’t stand a thermal decarb cycle, which begins at relatively low heat. The belt dryer is similar, lower heat but long contact time.

Has anyone seen a pre/post analytical comparison of product (dried biomass) on the IEC process vs. Belt dryer vs. a conventional barn dry process? I’d be curious of the impact on terps.

3 Likes

I actually work for IEC Thermo, and we just got our COA’s today. As you can see, the degradation is minimal. What makes it possible for the H.E.M.P. Dryer to dry while leaving these molecules intact is our extremely quick dry time, usually taking only about 45-90 seconds from when the hemp material enters the dryer, to when its deposited into a supersack. Often knocking off 50-70% moisture in a matter of moments, at a volume that is difficult to compete with(up to 15k wet pounds of biomass per hour).

Full Report - Dried Sample 1.pdf (1.1 MB) Full Report - Dried Sample 2.pdf (1.2 MB) Full Report - Lab Dried Sample.pdf (1.1 MB) Full Report - Raw Wet Feed.pdf (1.0 MB)

2 Likes

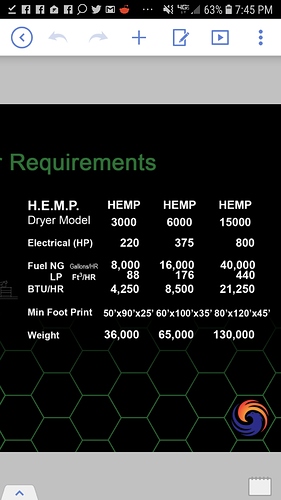

Can you clarify this? Units don’t look right on fuel consumption.

1 Like

IEC Brochure-email.pdf (327.5 KB) That Infographic is flopped on the cubic feet and gallons per hour, not sure how that happened, but aside the fuel consumption values should be pretty correct, (maybe one gallon or cubic foot off) I even double checked with our engineers to be sure. They’re based off the BTU and fuel consumption ratings of our furnaces at full blast, the 3000 with a total of 8,000,000 BTU/hour, the 6000 with a total of 16,000,000 BTU/hour, and the 15000 with a total of 40,000,000 BTU/hour.

The actual cost of running (fuel consumption wise) can vary based on throughput needs and moisture content of starting material. A higher throughput, and feed with a higher moisture content will tax your furnace and effect fuel consumption. I’ve found that more often than not operators of our dryer find a “cruising speed” that satisfies their throughput needs while maximizing fuel efficiency, which can be monitored by graph and adjusted accordingly from the Burner Control Screen on our touchscreen PLC.

Hope this clears things up a bit, if you have any other questions or concerns feel free to ask. I’m here on this forum personally to educate and promote transparency, but if you wanna know more technical information my email is Chrisr@iecompanes.com

Continuing the discussion from Recommendations for hemp drying equipment:

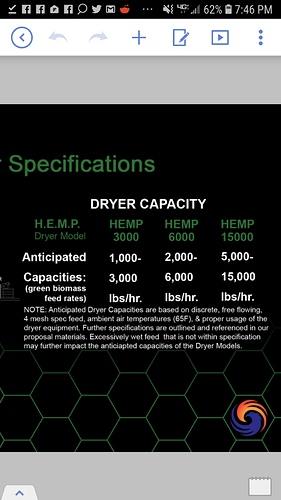

I work for IEC Thermo, a US based Dryer manufacturer. We currently manufacture 3 size dryers, 3000 wet lbs an hour max capacity unit, 6000 wet lbs an hour, and 15,000 wet lbs an hour.

Our dryer is a continuous feed two stage drying system which minimizes risk, maximizes efficiency, and is engineered with drying technologies that keep cannabinoid and terpene retention in mind, with COA’s with data that support that.

Shoot me an email at ChrisR@iecompanies.com or DM me if youd like to know more, otherwise you can visit our website at https://www.iec-thermo.com/