I’m sure you settled on a final design. Here are my thoughts.

If you are filtering from a centrifuge, as per your post, the biggest particles are the first needed to be removed, i.e. the biomass particulate that makes it into the stream.

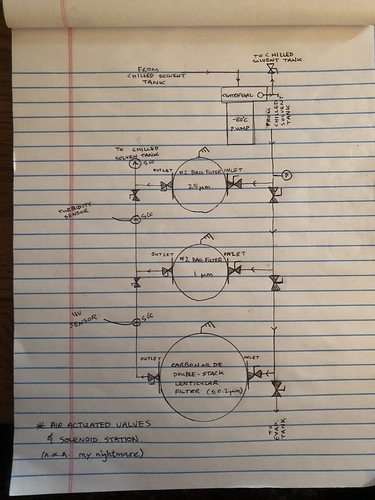

Step #1. I like filter bags in the 10-25-micron range for this purpose. Bags are cheap and swapped out easily. Bags tend to fill easily but, whatever, they are cheap. Use the largest bag housing you can afford. A valve to recirculate your solution at this point is recommended as some particles make it past the bag.

I would not use a cartridge in step 1 because they tend to be expensive. It’s incredible how much you can spend per year swapping $30 cartridges!

For step #2 I like lenticular with DE infused. This creates a depth filtration that takes particles down to 10 microns or so.

Step #3 is carbon adsorption using lenticular.

Step #4 we use a cartridge filter, 3x 30” cartridges to be exact, and can go down to 0.2 microns. We use cartridge last because not only will I capture any carbon that falls of my lenticular, but I can go to a small micron at a cheaper price than if I did this on my #2 step lenticular.

In the end, every time you have to swap out all lenticulars and cartridges, you will be out about $1,000 (for our size setup anyway). You want this to last as long as possible without sacrificing quality. I think this is the best way to do that.

About how to pump the solution through the filters, we love AODD pumps. When forced air is used, sometimes when you run out of solution in your holding tank, forced air runs through the filters at great pressure and well, breaks shit. This doesn’t happen easily with AODD. Also, you must use a damper with an AODD, which solves fluctuation issues.

BTW this is a plug for a filter skid we sell.