Ethanol only. I thought the question was for recovering ethanol after winterizing. I must have misunderstood. Ethanol only

Thank you for the response and what compounds are you able to separate with membrane filtration?

Oh just saw that no I’m talking about butane

These skids are designed for continous, 1 pass recovery of ethanol. We have a nanofiltration add-on that can be run passively off the concentrate outlet to remove most lipids, fibers, polysaccharides, and other gums. We like to follow that with either evaporation or louching residual ethanol out to retain terpenes. This gives a high purity crude that, after a nonpolar scrub, can produce high purity oil without distillation.

Cool cool. Now what about flowing 30-40lbs of butane rich with extract that’s already been dewaxed for separation of the extract from butane. Is that possible?

It definitely is possible. We would love to make that happen, but at the moment we don’t have any c1d1 booths that would make the needed experimentation safe.

Well sometimes you need to go outside the c1d1 box

I have never had a problem doing that, but scaling usually takes more than one person and I can’t take those risks with someone else’s life. If I were single and lived alone, I’d probably be doing it in my garage by now.

Haha I feel ya.

I have a couple 550 sq ft c1d1 rooms you are more than welcome to come run some tests in! I wanna see some butane membrane runs!

Where are you located?

Eugene OR

I’ll let you know if I think I could cobble something together. It would definitely be after May, probably significantly later. Hopefully not next year. I’ve built it in my head a million times. It should go flawlessly. That’s how that works, right?

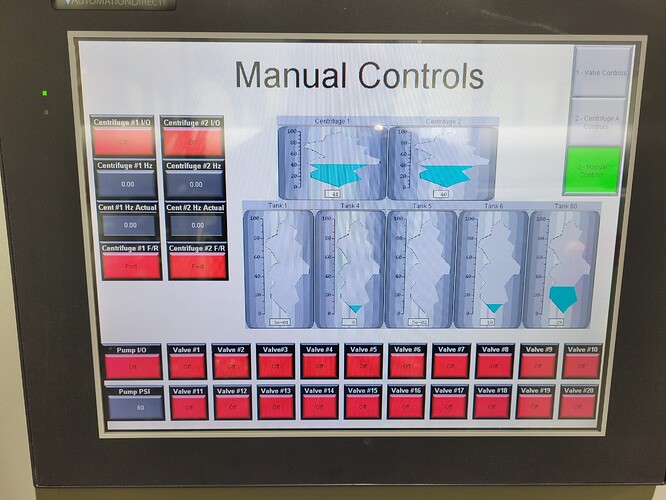

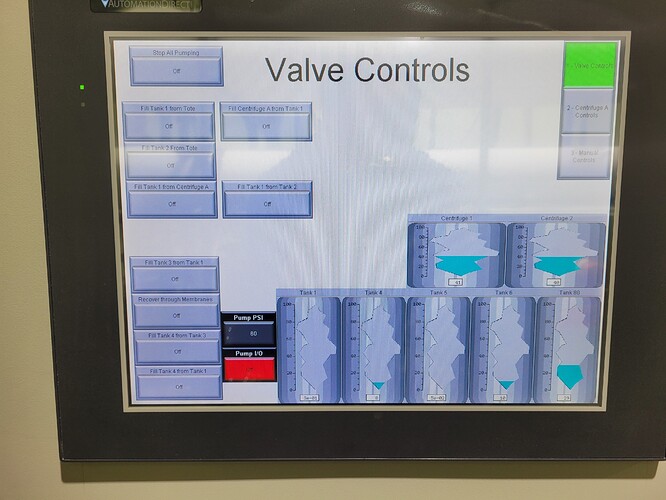

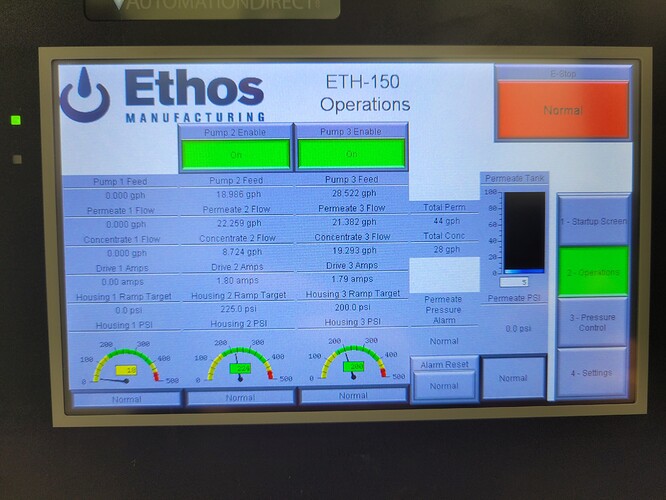

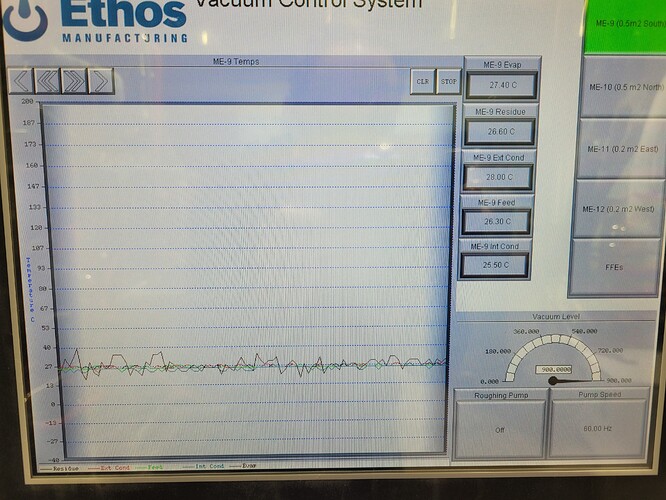

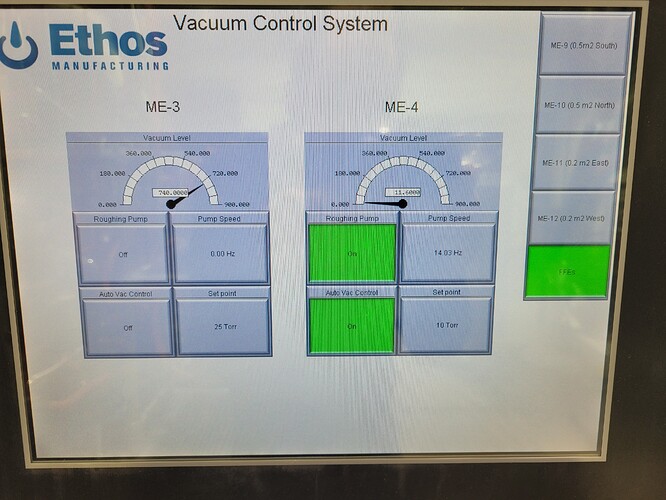

Here’s some shots of our control panels where you have complete control and monitoring of temperature, flow rates, tank levels, vacuum levels, and more.

Yes it is. We’re designing one now, but don’t have plans for building or testing it yet.

It sure looks like you’ve got all the right things in all the right places from an automation perspective. Good job.

Thank you! We’re really happy with the price and quality that we’re able to offer. We’ve spent a lot of time engineering and testing everything we sell.

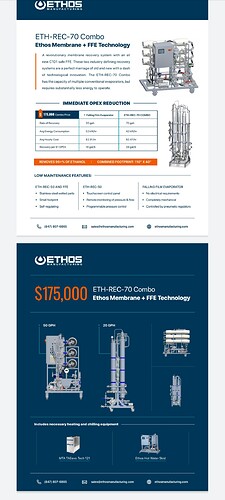

Our 70 GPH membrane-FFE combo is a steal. The unique thing about our system is that you can run a single pass of solution through them straight to an FFE to crude. Most other systems I see being run in batches. That’s the biggest advantage of our large cartridges. That’s also why we use fiberglass housings. Stainless housings on systems our size would make them dramatically heavier. We like being able to easily roll a 150 GPH system around the lab.

We are working on a continous line that goes from biomass to water washed crude without taking it out of the system. This would allow for extracting 1500lbs a shift with 2 techs.

Today we’re in OC finishing up commissioning of the 200 GPH skid. We pushed it to about 3/4 of its normal working pressure and with clean ethanol and a few degrees of heat above room temperature, we were recovering almost 250GPH. We slowed down the system and are finishing some last minute tweaks. The customer decided to delay extraction until tomorrow because we plan on extracting 160lbs an hour and going directly to a Trusteel FFE. We’ll feed it at 25GPH output directly into sealed decarb reactors.

From biomass to decarbed crude is in a completely closed system. The decarb reactors have pumps mounted on them to transfer the crude into the WFE feed tanks.

We really love these @TruSteel FFEs. When paired with our membrane system, they are continuously recovering 225+ GPH of ethanol. With no operator involvement. They never have to be concerned with the level of their solvent as they continously pump it back into the extraction feed tank. This allows the ethanol to be constantly refreshed for extraction. Fresh ethanol every pass, instead of taking it to max saturation. I could talk for hours about how sweet this system is, but I have to get back to the commissioning and training. I

Any chance you gonna make a video of extraction tomorrow?