We at Ethos Mfg. realized that we had taken our 150 GPH ethanol recovering system on the road to show some of the gang, but have never properly introduced our membrane systems here.

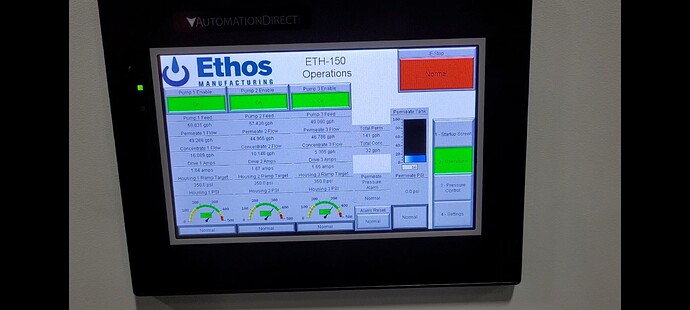

What sets us apart? Our systems monitor several different data points and logs them for future use. They are also automated to take much of the human error out of the equation. They use larger membranes than most which reduces the need for excessive cross-flow, saving energy and allowing for true, continous recovery. With the flow sensors across the system, you can recover in a single pass, and match the output of the system to the desired feed rate to your evaporator so you reduce tank space and excess stored solution.

These systems are designed to be part of our developing, completely-continuous system. They can also be controlled and monitored from a cell phone or tablet.

We are also working on UL approval for our system as we believe that will be the gold standard for processing equipment certification in the future. We already have become a UL licensed panel shop and offer in-house automation on almost all of our equipment.

There have been concerns regarding the compatibility of our fiberglass housings and ethanol. We’ve had our most-abused housings tested by a third party for solvent compatibility. They passed with flying colors and we’re awaiting the official report. The burst rating on our housing is over 1300psi. We rarely pass 350. After a couple years, the fiberglass has not lost any measurable integrity. We’ll continue to do testing as we have housings in the field over time and if there is ever an issue, we’ll take the proper steps to remedy it

We test our full size housings on our automated test skid which allows us to run several different programmed cycles so we can test properties of the membranes at the scale that we sell.

We can make custom skids of any scale. Above, are 2 custom projects. 1 is 200 GPH system with built-in redundancies to allow for full production during maintenance. The other is a 600GPH with pneumatic valves, digital recirculation control, and coriolis meter.

We have several other custom solutions that we can provide in terms of NF filtration and L2L ethanol louching without hydrocarbons all the way to isolation from your refined crude. We can also design/build your entire lab for you.

We’d be happy to answer your questions, if you have any. We reserve the right to not engage with certain competitors on the forum as at least one has made false claims regarding the safety of our systems and spread misinformation. We’d like to keep it positive, informative, and honest.