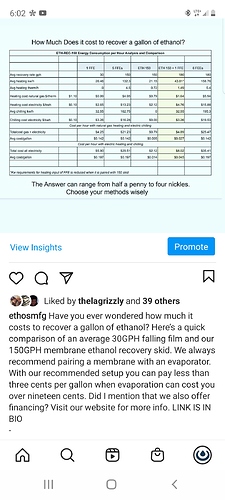

What do you mean insanely slow lol. If you have 1000 gallons of solution and the membrane removes 95% of it then you have to do 50 gallons a day in the reactor. That’s trivially doable. My tiny 10 gal reactor does 10 gal per hour and i could have made one many times as large. Remember this was a recommendation for small setups not huge ones.

SlapDaSack

I believe the 50gal was around 100k, and the 150gal was 200k ish.

I think you can run a 150gal membrane system + 1 FFE to produce the equivalent of 6x FFE. It’s more about optimizing mass production I think.

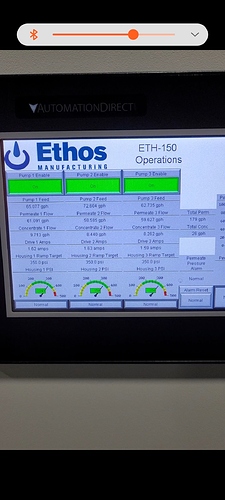

If any folks have any questions regarding the Ethos Mfg. ETH-150 recovery skid or questions regarding the use of membranes and their combination with evaporators, feel free to ask. We have 100s of thousands of gallons under our belt and several interesting products in the pipeline.

Please specify how the pumps are undersized. Do you have any data to back that up? Our team designed our skids to recover ethanol from a cannabinoid solution, not wine. The prototype ran pumps half the size that are used. They run at about 1/3 of their capacity. The background of the folks that designed this skid have used this technology in environmental remediation in the form of cleaning oil spills from soil, which is relevant because the target is a nonpolar oil… not a product of fermentation.

The average 8040 needs 40-50 GPM cross flow

That pumps is 10 GPM MAX youre literally throwing away so much performance going for low power requirements

Reduced cross flow causes quicker fouling and less lifespan, but hey if that’s your prerogative go for it

![]()

![]()

![]()

![]() I needed this evening

I needed this evening

Let teh discussions begin!

This was the pump attached to the system which i viewed:

It is rated at 4.2 gpm.

This is the technical manual for the membranes you’re offering:

45-D01704-en.pdf (898.2 KB)

Clearly stating feed for those elements should be taken at a minimum of 18 gpm and maximum of 50.

Even that is small as many other vendors recommend rates 60 or even higher.

Bahahaha that’s funny you remember those

Worst membranes ever?

Probably

That seems like an assumption from somebody that doesn’t understand the benefits of laminar versus turbulent flow when rendering ethanol from a hydrocarbon. Turbulence will clear debris and improve a nearly-fouled membrane, but will not improve throughput. It will increase the amount of energy you use and extend the time needed for an efficient cleanout.

13 posts were merged into an existing topic: Warning! Do not do business with UGC Operations!

It’s not a matter of remembering. I was called out a couple months ago by a disappointed buyer asking if there was anything they could do to improve membrane lifespan. Said they were failing within a week.

Those calculations are based on the desalination of water and don’t translate to this industry directly.

XD oh man I know too much and I’m saving my HEAT

Lmao turbulence?

These membranes are rated for high cross flow, youre not going to have “turbulence” if the skid is designed right (which you’re isnt)

Slowly moving the retentate across the membrane does increase chances of fouling, this is a known fact in the nano filtration world (also one of the reasons your customers have problems)

I’m blaming the wine… If you pull it out of me

The membranes I use are rated for 50 gpm+ and they go all the way from micro to nano filtration (and RO) sizes

The membrane pore size doesn’t effect the cross flow ability of the membrane

The amount of surface area is the same unless you change the spacers

![]()

![]()

![]()

![]()

![]() .

.

![]()

![]()

![]()