Carbon Chemistry Sale: 10%carbonchemsitry

10% off all Carbon Chemistry that’s listed on our website through the entire month of October.

High-Flow Kit updated to .270" orifice opening, 35% increase in size, scroll down.

Dual Pump Conversion kit, scroll down

EDIT SALE ITEMS, LOOK BELOW

Sale on WAX TRAPS. sale $199 each

Individual Wide Mouth Borosilicate Bottles for $15 each.

Sight-Glass Sieves, sale $225, 3/8" and 1/2" end caps available

Activated Alumina from Carbon Chemistry, 14KG, sale $160

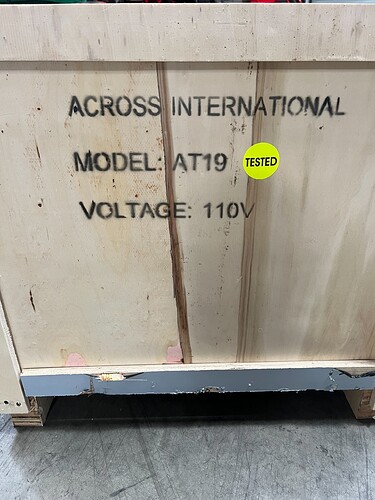

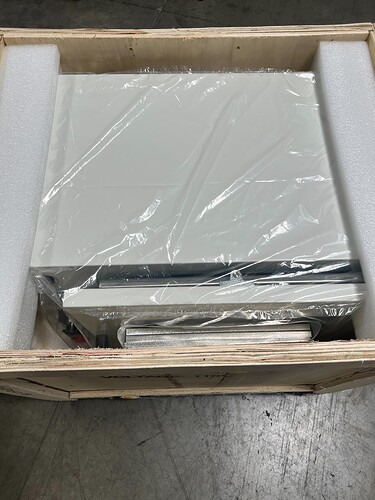

(4) Used Across International AT19 vac/oven with UL cert, $1,000 each, scroll down

Used Collection Vessels, 150L conical bottom, 150L, 300L, scroll down

1.5HP Flameproof Motor, $300

Hello Future4200,

My name is Aaron and I work for EcoGreen Industries. I’m not the same Aaron that worked here previously, for anyone that may remember him. I’m not just someone hired to chat on the internet either. I actually work at the company, and not just from behind a desk. I can usually be found in the shop working on customers pumps, tig welding some stainless steel, helping to load and unload trucks, talking with customers, and/or figuring out how to make new ideas work so we can test them to see if they are viable. I’ll be checking in to post things and to help answer any questions that you might have. If I don’t know the answer, I’ll find someone here that does and get that answer for you, or just flat admit that I don’t know.

We have been busy this past year testing a few new ideas in the shop, trying to find better options and products for our customers. One of the newly tested products is our EGI High-Flow Kit for all three generations of the CMEP-OL recovery pump. This eliminates the factory valves that are horribly undersized, and upgrades to larger orifice hoses with optional larger orifice valves. Some customers don’t want valves, so they are an option for now. We are now offering the same replacement crank bearing for the CMEP-OL as we have in the past, but also an upgraded Ceramic Hybrid bearing. The new Hybrid bearing can operate at higher temperatures and handles the rpm’s better as well. To go with it, we are using a new non-toxic high temperature grease that’s good up to 1,400 degrees F, with a drop point of over 600 degrees F, and does not contain PTFE. This eliminates the worry of any off gas from PTFE grease that may reach over 460+ degree F. And we have also tested and have available a replacement motor for all generations of CMEP-OL that upgrades from 1hp to 1.5hp while staying with 115 volts.

We offer media from Carbon Chemistry, Media Bros, and BVV. We have large stocks of all our stainless steel fittings and continue to make custom hoses for customers (all pressure tested). We have new and refurbished CMEP-OL recovery pumps in stock and ready to ship out. We also have the large 710 pumps in stock with single phase or three phase motors. We sell MVP and Corken pumps as well. We stock columns, wax traps, sieves, gauges and more. And we ship solvents in and out all day long and store them in our indoor storage facility. Tanks and totes are not stored out in the weather here.

I’ll update this thread with pictures and products so people can check them out. If you have questions, please ask.

Thank you Future4200,

A-Aron