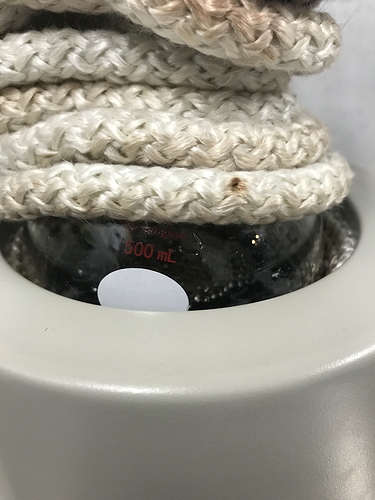

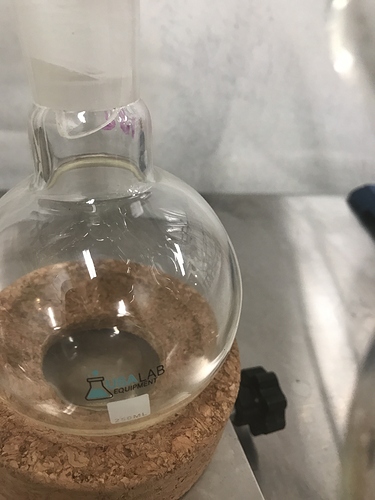

This look right so far?

Looks like a gentle decarb to me. Let that settle and keep on going.

Nice keep on going!

Best of luck, man!

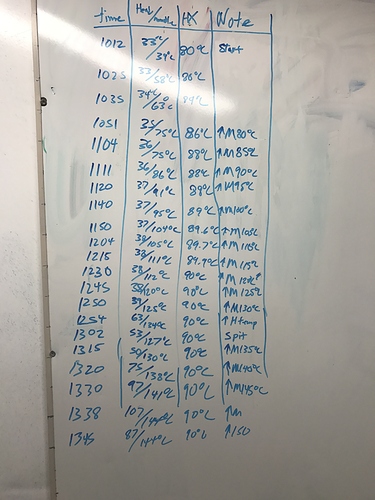

https://future4200.com/uploads/default/original/3X/7/4/7485785197f328228be8ffaaac251b170a68d03b.MOV any feedback on when or how fast to raise temps based on the look of the oil in the mantle?

The thing I learned from my first SPD (particular the first pass) is that you can go really fast.

Here is my process;

If doing decarb:

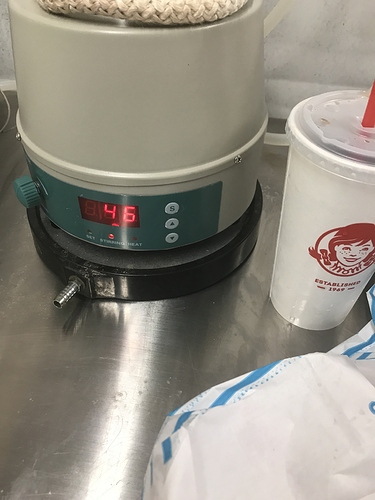

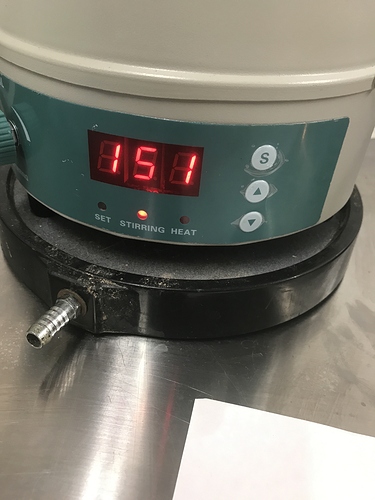

High spin, get to 135 on mantle as fast as possible. Decarb should be pretty much done in 30 minutes. Turn of spinner occasionally to see if you still have bubbles. If not, go right to 160. When it reaches 160, go to 170 repeat until 210-220.

You should start seeing heads around 150ish, depending on what is in your stuff.

When head temp reaches 165+ you are typically on mains. When it runs clear switch to mains. You should see head temps around 175 to 195 (high end) for several hours until you get to tails.

My first SPD took like 12 hours because I babied it a lot. Now my first pass typically takes 4-5 hours on a 2L with about 700ml of crude.

Second pass you can be a little gentler.

Make sure you don’t pull too much vacuum during decarb, since it will cause other gases to bubble off and fool you. Decarb looks like a soda fizzing.

And if you run for like 12 hours you will get some really nasty smelling heads and in the cold trap. Remember head temp tells you everything. At the end of the mains you will see temp typically rise then drop rapidly. You can squeeze more out of it in your first pass by raising temp up a little. I never go over 235 on mantle. If nothing is happening at 235 I call it a day (if head temp is low also).

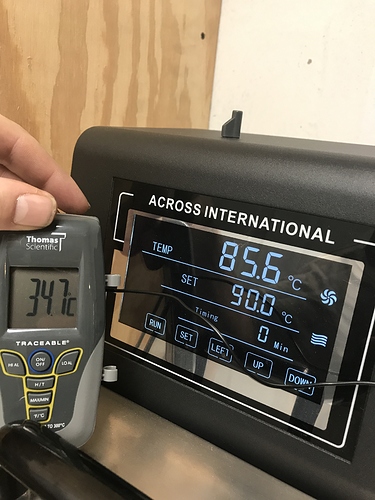

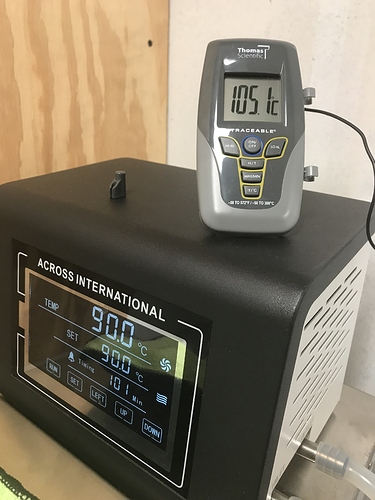

Why 90 degrees on the chiller? Isn’t that a little warm for condensing the undesirables?

I run 66 on my chiller, which is right around 63 on the head. I know there is a hot condenser tek, but for what I do now it works ok

Lol I don’t think I ever get above 60

Thanks for the info much appreciated. Im under the impression 90 is good temp for chiller but maybe i was misinformed.

I was told to rely more on the cold trap than the condenser

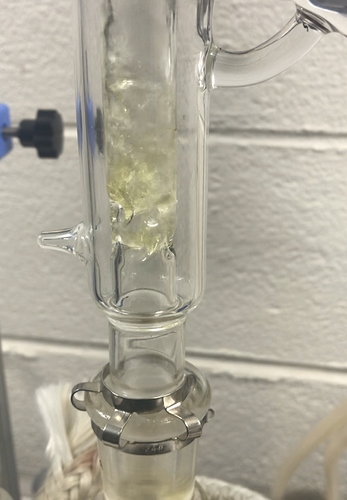

Also, my first pass never looks super pretty. It has streaks etc. Second pass is when you clean things up. I also do LLE and magsil column between first and second pass which really makes the product beautiful.

Also, make sure you have a heat gun handy in case you get a clog. Without it you can be SOL.