Hey guys, I have been scouring the internet for affordable solutions to implementing gear pumps as discharge pumps for SPD/WFE systems. I understand B&W have a pretty fancy looking pump for that purpose, but the price tag makes it not very lucrative.

Searching fleaBay yields a plethora of used and quite affordable pumps. I have found multiple Micropumps that look like they might work. It seems to me that by adapting the NPT thread on the inlet to an SPD or WFE would be quite trivial. My problem has been finding a vacuum check valve that could be used at distillation pressures. Does anyone know of any that would work?

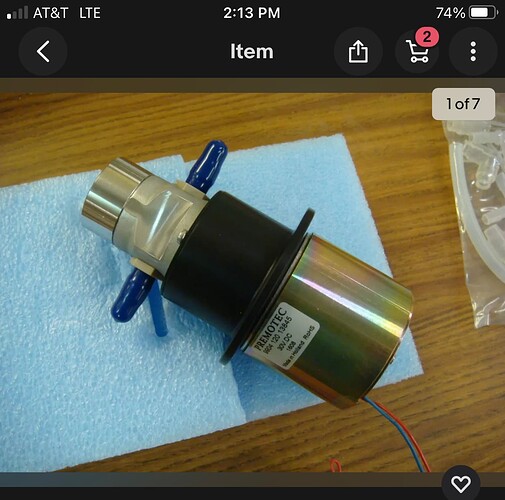

This is kinda what I’m thinking:

4 Likes

Check McMaster Carr.

Swagelock also has some good solutions, for check valves.

So I’ve got a decent idea how check valves work, but I’m not really sure how high vacuum plays into that. I’ve checked mcmaster multiple times but nothing jumps out at me as “I can work at very high vac levels”.

I also found this page with check valves and it lists the Cracking Pressure as 0.58 inHg / 0.14 psi. Does this mean that the gear pump will need to put out that pressure to produce flow thru the valve? When I first read it I thought it meant minimum vac level but now I’m not so sure. Would you think the 1/4in Aluminum check valve would work?

The pragmatic answer is that no check valve is going to work exactly as it should once you start running viscous distillate (or worse, tails) thru it. Remember that under perfect (or even good) vacuum the only way to move a liquid is with gravity. Low npsh value pumps are good for avoiding having your vac level fall to an unacceptable level but ultimately they are just augmenting gravity to push your distillate from one high vacuum area to the outside at or around 1 ATM (depending of course on your elevation). They physically can’t pull hard enough against a high vac environment to suck out the product coming off your condenser. A check valve just makes it so that during startup or when a pump runs dry it doesn’t completely ruin your vacuum inside the distillation equipment

2 Likes

So basically the column of distillate that is in the inlet tube and inside the pump is what actually makes the “seal”. The check valve is just to allow time for distillate to accumulate in the inlet to prevent air from getting in. Is that what you are saying?

4 Likes

Exactly.

You really don’t NEED a check valve if you coincide your distillate input with vacuum on sequence.

You could alternatively use a shutoff ball valve between your pump/distillate feed tank and your WFE wiper inlet port.

Open the valve when material is loaded and vacuum can pull down while valve is shut.

2 Likes

I had considered the ball valve hack but didn’t know if that would be the cleanest way. Definitely wouldn’t hurt if one were to have issues with the pump as a way to isolate it. Appreciate the tid bits to chew on. I’m thinking about gambling 1k or so on an eBay gear pump, a check valve, and the associated fittings just to satisfy my curiosity. One of these days distillation may pay the bills, but not today. Can’t allocate big money for small projects.

1 Like

You can use a silicone cart butt cap as a pseudo check valve by starting main vac and placing it against the outlet. Then when the distillate starts it falls off.

5 Likes

I think its worth a try.

(long winded but this check valve topic here has bugged me too for years, to the point ive kinda given up)

RE: Gear pump

One challenge you might run into is pump slip / any temp effects on the gear/seal system, but I wouldnt over think it if you got some bones to spare to a fleabay pump that is speed controlled. Always worth calling the mfg with the part # and making sure you know the exact specs of what your buying. Not sure what your flow rates are but Ive wondered about gear pumps from the resin/adhesives metering industry for sake of temp tolerance and such. I think theres another thread here on gear pumps for wipers…if i can ill add a link

RE: checks

After using check valves on wipers for years, trying to find “the perfect one” (longevity) hasnt turned up an off shelf solution, you can weld a jacket or if not wrap in heat tape/nozzle heater (just mind ya temps). ive used 1/3 psi cracking pressure and as much as 5psi cracking pressure, if your pump can handle it the higher crackign pressure chekcs seem to seal better with cooling disty but i think that issue can be mitigated with where you place it in your line and temp control.

Seems the residue/slag and CBD crystals have given me the most trouble in checks. Ive used swagelok poppet style and a couple types from Check-All, they tried to sell me on a NiFlon coated check but it was like 450$ so naa . I really like the idea of their very low hold up checks that go b/t flanges/ferrules but havent tried myself.

Ive tried getting those jacketed check valves the chinese wipers are using, i doubt theyre perfect but anyone here have long term experience with those? I think its possible someone could make a better check for this app but…

That said, I now prefer the ballvalve+liquid column method as its most robust and available today.

@anon45638961 I saw a VTA Stainless unit that the tech was using “plugs” for the discharge nozzles upon startup LOL! I think VTA knows putting checks there would be more trouble than its worth (with customer complaints) for disty and residue.

2 Likes

It seems to me one could design a check with a ball bearing (or a fancy seating plug) and stiff spring on a beefy oring using just a lathe and some talent. I feel like if it’s not going to be a long term solution it should at least be rebuildable.

I REALLY appreciate you sharing your experiences on the topic. I have fixated on gear pumps and check valves for this application for a year now (without buying or playing) and usually by now I would have long solved the issue. At this point I guess I just need to order some shit and fail fast if I’m gonna learn any more because reading and doing are 2 separate things!

6 Likes

I REALLY like this! Something about completely dumbass solutions that work super well tickle my fancy and I could see this actually working quite well tbh!

If this were true then steel yhchem units wouldn’t leak air through there discharge pumps and they do (they also don’t have a check valve)

A check valve prevents any back flow from occuring by closing when nothing is being pushed through in the direction of flow

Ask anyone who actually works on wiped films, they’ll tell you you need check valves. Search around the forums and see what people say when the B and W check valves don’t work right (you’ll see people have nothing but vacuum problems when the check valves leak because even with the pump on air still wants to get pulled through)

2 Likes

So what’s your solution then? Let’s all contribute! I’d wager the Chinese pumps don’t have the tolerances to not leak. I’d say an American jobby may or may not have the tolerances to work as described above. I do agree that a check would act as a buffer between the feed rate of the pump and the air rushing in.

1 Like

I’ve used Chinese pumps, German pumps, American pumps

All of them leak under deep vacuum, even the German made vta pumps have check valve because they leak

I built my own pumps because I hate B and W and think they are over priced

The setup above cost me about 1500 bucks to make with pump, motor, vfd and pump support plate. I’ll put the check valve coming of the front and bend some pipe so the distillate is directed down into a bucket

I’ll wrap heat tape around the pump and check valve which will he controlled by my 8 channel heat tape controller I built

I basically built all my own shit after using B and W stuff and hating it

Here’s the feed flask I built that the heat tape controller mounts on. It uses a liquiflo American Made pump that can go up to 500f. This feed flask does 30L an hour but could do way more if I put a bigger motor on it

Definitely use a check valve, if you want to see what I’m talking about try running with a plug like they were talking about above and watch your vacuum slowly creep up once the disty pump is turned on. After attach a check valve and watch the vacuum stay the same.

Try it and see

12 Likes

Dude! Every bit of what you showed looks clean as hell! I appreciate you dropping that spoon about the liquiflos. I bought a mag drive for my flow cell and couldn’t be happier!

That 8ch temp controller looks trick as fuck! I had fun building my diy cart farmer.

What check valve would you recommend?

Did you have that gear pump head machined or is it jellybean? If you had it machined, what would you charge on just the pump head if I wanted one?

3 Likes

These are what we use in a pinch, im ordering basically the same thing from China since you can get them for about 1/4 of the price if you order bulk.

It seems mcmaster is out of the 3/8 for a while which sucks that’s the one I usually use

You rock brother. You played with any of the micropumps? Seem like a skookum little choocher but I’m open to suggestions. Probably looking at ~1L an hour with current kit.

Often times, SHUTOFF VALVES are built on the feed vessel of WFE’s before the feed pump or wiper inlet lol. But thanks for sounding conceited again.

Lots of ways to skin a cat.

Having sold and installed tons of YHChems,I’m one of their only US distributors, I can say they run fine as they are sold.

I work a ton with chemtech/helderpad as well, almost weekly.

You don’t know me, you know that I like pointing out your unintelligence alot. And it seems to really annoy you lol.

1 Like

Have you ever worked on anything other than cannabis systems?

Have you spent a day in a chemical synthesis laboratory, other than for cannabis work, on your life?

Common industrial processes apply for cannabis too. You’re not inventing anything new.

Valving off the flow before filling your feed is what we do in the petroleum & oil and gas industry for fractional feed.

You will only get leaks or experience decrease in vacuum level if you allow your feed tank to go below half filled or so, or if you feed too fast for the viscosity you are dealing with, and even then it’s not a consistent leak if you watch your flow speed carefully.

1 Like

Seems to me like you’re just tryna sell your motor/pump configuration.

Kinda weird plug lol, but cool.

OP was asking if he could get away without using a check valve and the answer is yes as long as you watch your feed vessel levels or flow speeds closely…