If he’s the only one getting it the give test batch biomass to someone to run …if it doesn’t happen to them it’s your gas or system…maybe a gauge leaking into the pot. If it does happen to them it’s biomass related…do you have .22um filter?

There simple test to see what to look at I know u know someone w smaller system to do test batch

From his most recent post it sounds like he has not started with new fresh gas yet.

Swapping hoses and cleaning everything doesn’t help if its the gas that’s contaminated

There are bubbles escaping from the crystal as it dissolves in the acetone. Is it pressure from this entrained gas that is slowly cracking the crystals apart?

Are the crystals forming too quickly or at too high of a solvent pressure to allow them to exclude this gas as they grow?

Have definitely started with new fresh gas! Moment we swapped gas suppliers we emptied/cleaned out 2 of our solvent tanks, distilled into them, cleaned the lines and system again. When we started receiving the same results we swapped to a 70/30 from the previous supplier to check (since we had an old tank on hand). Emptied and cleaned 2 other tanks, distilled, cleaned system, same outcome.

Will be trying a new gas supplier this week to do another little test on a separate system first then on the big system in fresh tanks.

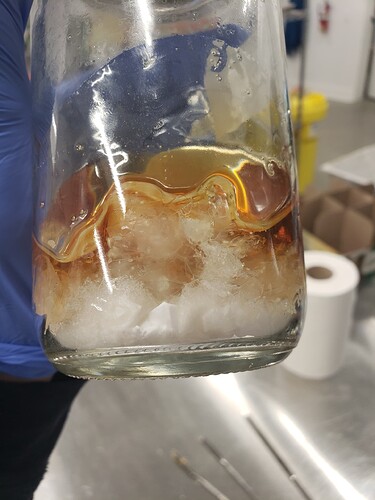

Definitely forming quickly; outside of normal growth periods for sure. So wouldn’t put gas sticking in the rocks past me. Will be sending in some samples today for residual testing. Have a jar where the top portion chalked up and the bottom has not yet so will be trying to preserve some of the bottom for the test before whatever is inside escapes.

Mixed some disty with non distilled gas as well so will be sending that

Sending a fully chalked rock as well

It’s the 5G

But for real, interested to see what’s causing this…

My guesse : fast solvent evaporation in a porous cristal. Shrinkage occurs due to the liquid-vapor interface of the receding solvent which exerts capillary forces on the pore walls. These forces cause the pores to collapse in on themselves and the cristal will shrink. Cracking usually accompanies this shrinkage, micro cracking in this case, so transparent to opaque microcraked structure.

I agree and test the chalk too. Something weird for sure.

How many people has this affected and when did it start?

What do you do with the chalky thca to fix it?

you can re crystallize in pentane, seems they come out fine afterwords. Would prefer not to use pentane at all tho. When we re crashed in butane it did the chalk thing. The easiest thing to do is crush it up into thca powder. For the longest time we though it was something with our equipment, something getting left behind, and thought there was no way it was the gas as then there should have been tons of people having the same issue. Then I thought well maybe other people are having this issue and are not talking about it. I had seen some suspect jars on peoples instagrams that looked like they were having similar issues but no-one to confirm. The biggest kick in the balls of this whole thing is everything was working perfectly normal for months on the current equipment, then out of nowhere every diamond run would do this. Since we dont only run diamonds, it wasn’t something that was caught right away as all other consistency’s are not effected. Nothing shows up in any lab test. Plus the diamonds structures we were getting were so nice looking there was no concern until they got broken out and what ever impurity evaporated.

Still waiting for csun to give back results from testing the chalk diamonds, non chalk diamonds. A friend has access to their nmr and we were hoping it would find something these regular labs are not seeing.

Photo Dump/Testing Results Update :

Did 3 tests which came back pretty inconclusive. Did 1 test of a already chalked diamond. Did a test of a diamond we knew would chalk up post separation. Did a test of distillate + non distilled butane straight from the tank.

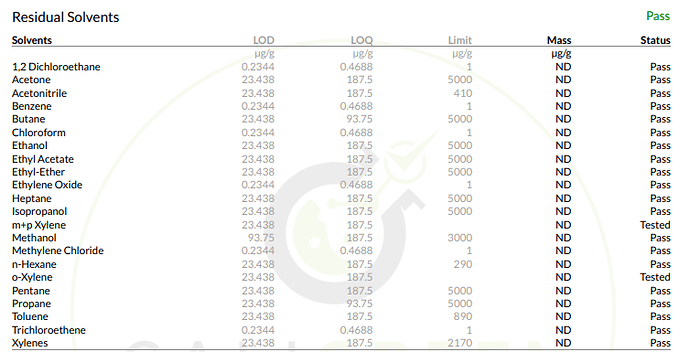

Chalk :

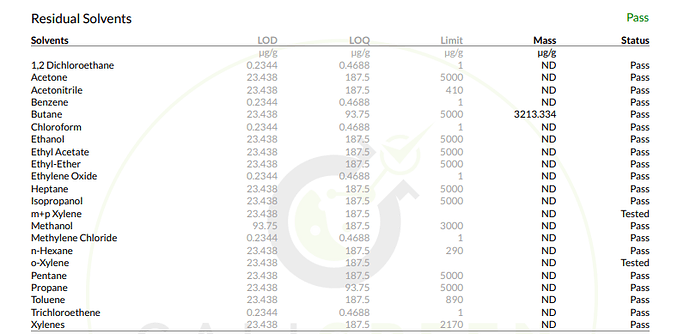

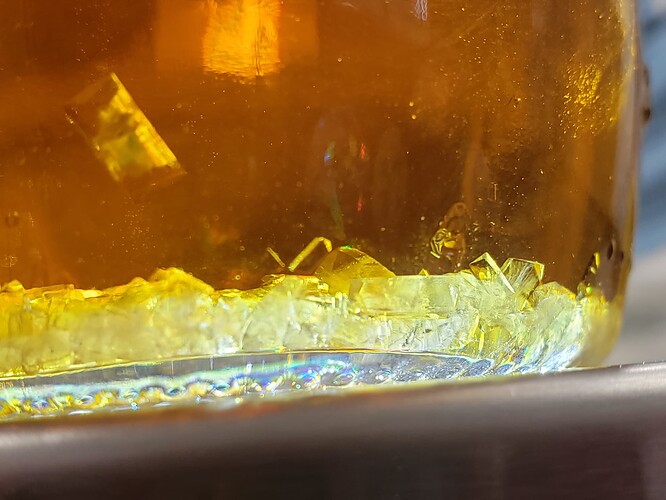

Not yet Chalked (grabbed this one from the jar before it had finished purging) :

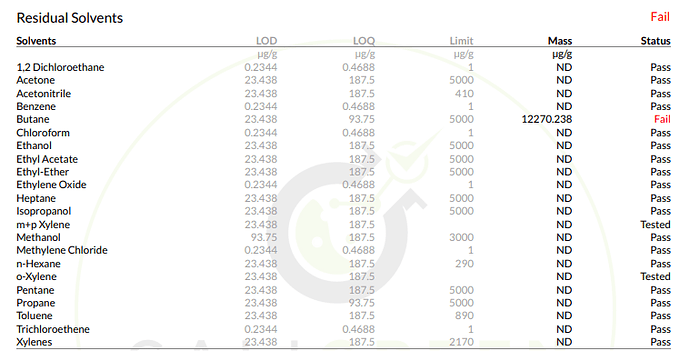

Distillate with non distilled butane :

No benzene in any of them. Sent more tests in today with material that we had ran about a month ago to check those out.

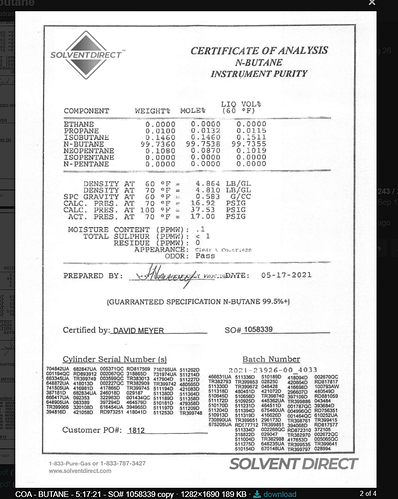

We have since swapped gas suppliers from west air (used for the images above) to solvent direct. So will send some similar tests out with the new gas. Though the new supplier is not looking promising either. First runs with their solvent are reacting the same as previously. Strange formations and accelerated growth. Though no mystery oil during the distill. We have also started seeing jar’s chalk up pre separation as well as our more sugary pyrex pours are starting to chalk up.

West Air 61lb distill (ring of oil) :

Solvent Direct 61lb distill :

Photo Dump section :

Pyrex:

In Jar:

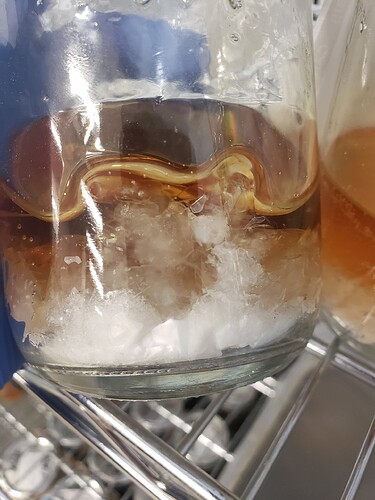

These jars were ran with west air : 3 days after pour

These were ran with solvent direct : 6 hrs after the pour

This is the COA we received with the solvent direct butane :

Still inconclusive as to the cause. Only remedy as of yet is recrystallizing in pentane. I have contacted a couple LPG manufacturing/distribution testing companies to see if they will test for non producers/distributors to see if they will come up with anything different on their test results.

My only guess is some weird micro-nucleation. You can have migration of defects within an established crystal matrix.

I’m still betting on 5G

I’m blaming it on biden. Chalk diamonds didn’t start till he came into office

All the formations are nice though.

If you guys have to re crash skip the hot jar and just cold crash it all into chalk and re crash

Would actually be Interesting to see you dissolve all this chalk and then cold crash it to see if anything falls out or if it re chalks or if it’s bizzaro thca and turns Into pretty diamonds at -80

Maybe this is all because we live in a simulation and the computer is breaking down.

Maybe people started spraying something new on their shit, maybe a batch of foliar product got contaminated with something

Move them into a warmer oven and see what happens. 75°f to 79°

HAHA man i love your style

Next time you have one that starts like this, move it to an oven around 75-79 and see what happens

Was wondering why he hasn’t changed his SOP just to see if it made a difference. I know that its a new thing and his SOP was not doing this prior but seems like he eliminated just about everything.

I texted his boss and went around waiting for a response. He’s also typing right now