#decanter centrifuge

#wastewater dewatering

#sludge dewatering

sale@kgcentrifuge.com

contact info:+86 199 5119 9986(whatsapp/wechat)

Emily for Jim Gu

Looking good! What certifications does it have?

Are you interested in this?

Has anyone on the board used a decanter centrifuge for cannabis extraction?

I am very interested to hear experiences if you are willing to share. I have been reading about them lately and the technology looks very promising.

They are a highly efficient machine for separating solids from liquids and can do a lot of work in a small footprint.

I think you could basically mix cannabis and solvent directly in a huge holding vessel (no mesh bags needed), do your soak, then pump the slurry into a decanter centrifuge to separate the liquids and solids. You could do large scale extractions in normal holding vessels and not need large floodable centrifuges.

@Emily Can you give us more information about different sizes, costs and throughput for these machines?

BZB just dropped one… they’re gonna be the next hot ticket item I bet you a dollar.

Yup they’re the future for scalable extraction. These I find to be a little wary as the size is massive. The one kyte had on display could do pretty solid amounts. These look capable of thousands of pounds slurry every couple hours

Could you skip the vessel. And have bio and liquid feeding it two inlets one sprays one augar?

I agree these look like a winner if they work. Companies like to show off the giant ones but there are also much smaller ones available, maybe in the $20k range.

How many less employees would you need and how much better would your throughput be if you could just mill biomass and toss it into a soak tank instead of having to load/unload mesh bags and load/unload a floodable centrifuge all day?

Has anyone seen that video on Mile High Labs page where the worker is using a manual lift to dump a 55 gallon barrel of biomass directly into a soak tank? I wouldn’t be surprised if they are already using decanters. I would bet if you bent a professional process engineer’s ear they would suggest decanter centrifuges for our purposes in a second.

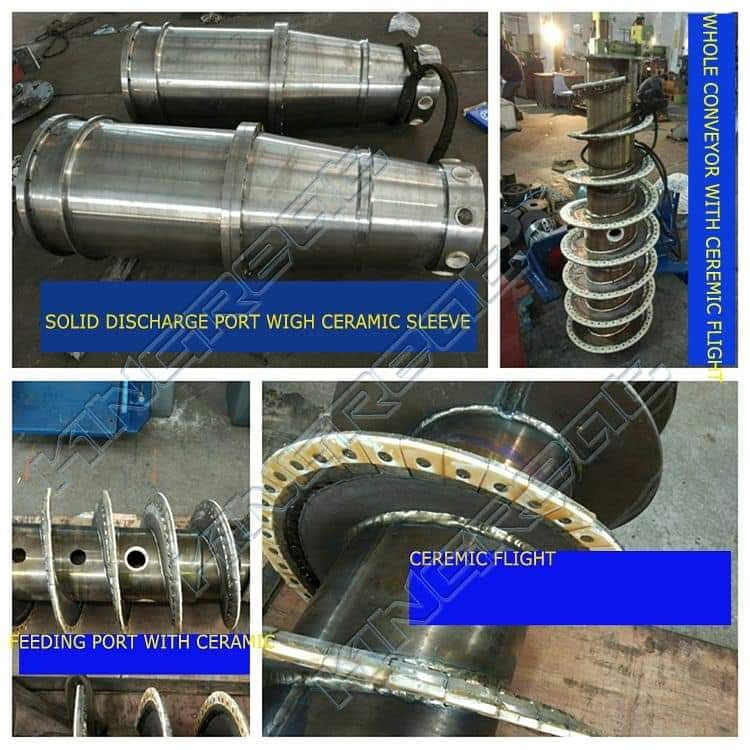

One thing I’ve noticed is that the most common models made for de-watering and sludge thickening typically operate with 3000-5000g’s. I have found a couple sources that say for separating things that are “soft” or “very fine” like biomass or yeast may require a model with a slightly different internal configuration and higher g-force, around 10,000g’s.

Flottweg Sedicanter

@Rowan more like BZB will be reselling them from a manufacturer to people who want to pay a premium for BZB to source them and explain how to integrate them. Typical cannabis industry rigmarole, but more power to him if people will pay.

@Champone I’m not sure I understand what you mean but I think a soak tank is needed to allow enough contact time for the extraction to take place. There is not enough residence time in the decanter for that. This machine separates the biomass from solvent/oil solution after the extraction has taken place. Like a giant settling pond on steroids.

The residence time in a standard decanter is like 2 seconds. Certainly something like this could be used for counterflow extraction, but not exactly this.

I understand now thank u

Interesting

I’ve always heard that the decanters squeeze your biomass way too hard and squish out all the crap we don’t want into the solvent.

Too big of an investment to muck about with

in my mind unlesss you’re already doing traditional room temp extraction and having to remediate that stuff anyways.

I know the manufacturer that BZB is importing through, when I was in China last year one of the companies I was considering was bragging that they were working with him, even gave me a copy of the drawing for his fuge design. Needless to say, I decided not to work with that company.

Has anyone looked into the decanter centrifuges more? Just wondering if I should look at these instead of a normal centrifuge.

I have one. The one pictured prob has about 60-100gal/min thruput rate. Think you can feed one?![]()

![]()

![]()

![]()

![]()

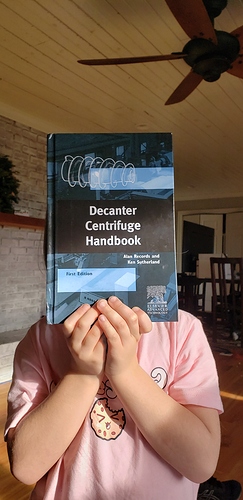

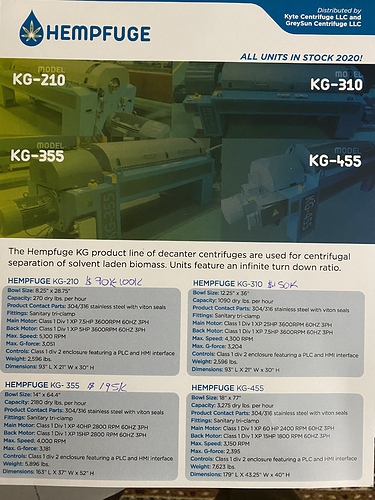

They extract 70 to 80% liquid from biomass so secondary recovery is required if you care about your remaining solvent. One company has put two in series as a solution. New cost is about 500k, used start around 80k. Many styles and variations available. There is a $300 decanter centrifuge handbook inhave that is informative if you want to know the math and details to design/build one.

Unless it’s a second or third wash, that solvent contains the cannabinoids…so yeah, leaving it behind is a non-starter

The USA company selling them at MJBizConNEXT has been doing these a very long time and they are called lay down centirfuge

don’t be silly. according to the 1k word substitute you just posted.

they are called “hempfuge KG-xxx”

Distributed by Kyte and GreySun

this style of machine are called decanter centrifuges across industries. even calls them that in the cut sheet you posted.

where on earth did you get “lay down centrifuge”?!?

certainly the all knowing one has never heard of such nonsense.

https://www.google.com/search?q=lay+down+centrifuge