Hey all. Does anyone recommend a company to order custom sized heat mats?

I have historically gone with…

Omega Engineering - they have many sizes, but not every size imagined and they also have the longer winding tapes available.

Also they have solid warranties and their indicators and such are pretty great too.

They also have pretty cool and inexpensive SAMPLE KITS so you can try out different styles and see which one works best for your project. Made right here in the US - and let me tell you, the kind of service you get from Omega is pretty stellar. Nothing like a woman started company that’s been around for decades to get you where you are going. <3

When they cannot do my project - then I go with All Flex Solutions. They are right here in the Midwest (local matters to me…) and they can make fully custom solutions. It takes longer to get things from them (cause they are making it just for you…) and they usually cost more (again, small batch just for you).

Their “build a heater” tool is kind of wonky. But once you are in the quote pipeline they will assign you someone to help get you through your project.

Probably there are other places that you could go. I go with these guys because I’ve had success in the pass.

I’d 100% go Omega for just about anything I needed, even if it cost a little bit more because they stand behind their warranties and fix things right away. And time has always been important to me. ![]()

Good luck and let us know where this adventure takes you. Which path you picked or if you went on a completely different path. <3

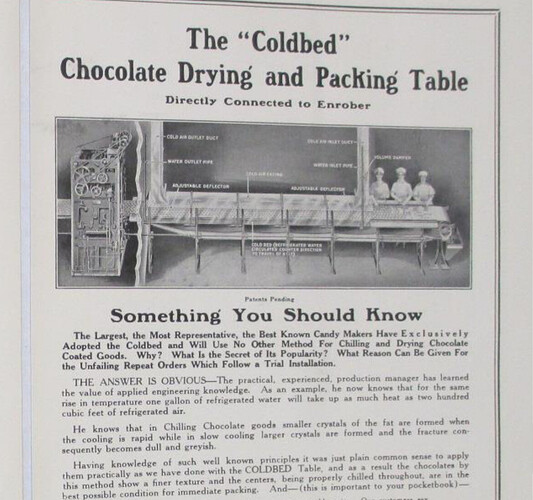

You posted under edibles, suggesting your use case might be a “cooling table” (yeah you asked for heat, but trust me…).

The cold table includes a pressure release valve for safety and rests on a robust frame with adjustable feet for level positioning.

Multi Purpose Hot or Cold Table Configurations

- Cold Table Configuration: By channelling cold water only through the system, the entire table surface can be utilized for product cooling, ensuring consistent tempering of confectionery items.

- Hot Table Configuration: Alternatively, a hot water flow through the table’s water jacket transforms the entire surface into a hot table, suitable for processes requiring heat.

- Dual-Temperature Operation: For simultaneous cooling and heating, one half of the table can be piped with cold water while the other half circulates hot water.

- Semi-Automated Batch Processing: For operations with continuous batches, one half of the table can be designated for cold water flow. The residual heat from consecutive batches on the non-piped side maintains a warm surface, offering a pragmatic solution for simultaneous cooling and heating without the need for constant water flow on the heated side. Cold Table - Candy Making Equipment by Loynds

You can get them in many sizes, or build them to suit.

ETS even sells little ones…

Depends what he’s trying to do and batch size. You absolutely need a heating table if you’re doing image candies or large batches.

sure, but does it really matter what you call your “plumbed for heat exchange” table…because you can heat or cool them?

Except when trying to track them down (new or used)…“cooling table” seems like a better search query.

There are certainly a bunch of other reasons one might want custom heat mats…but for precision control of one’s table top temps, I think the device referred to above is the most flexible solution.

Do you disagree?

It really depends what he’s attempting to do. You can use marble or granite too in lieu of a cooling table but if he’s making infused hard candies (or hard candy period), you’re generally not going to want to wait for the same table you were cooling on to heat up to keep the candy workable. There are a lot of ways to skin the cat, though.

Yep. As noted above. Flexible…

We absolutely looked at sticking heat mats to a table for our hard candy work.

We grabbed a used “cooling table” instead. Looks to have been part of a conveyer system in the past….

Yep, and I (we) am still guessing at what flavor of cat needs skinned.

Figured I’d share based on that guess, because even if I’m wrong someone is gonna find the info game changing….

Agreed, I found so many duh moments from the suggestions of others, one mans chilled ceiling is indeed another mans heated floor, or in this case table lol

Unlike Omega, Watlow does make custom heating pads.

I’ve used once upon a time when replacing the OEM pads on a heated press I salvaged for use as a rosin press.

My guess is that Omega gets their pads from there.

https://www.watlow.com/-/media/documents/catalogs/flexible0124.ashx

I haven’t used Watlow - but I have used Omega for years. I get all kinds of components from them.

Did you get good service from Watlow? They look pretty cool (so many patents!).

The photos of the Watlow stuff doesn’t look like the stuff I have received from Omega in the past - but that doesn’t mean they aren’t working together. ![]()

I’d love ot know more aout your replacement pads! Tell us more.

I too have used Omega for years, and agree they are solid (you pay a premium for that)…IIRC is was a nuclear physicist that pointed me in their direction, but I’ve been referred there by multiple folks when looking for sensors or controllers.

Watlow on the other hand actually makes “heaters”. flexible & otherwise. they also make controllers (you’ll find those on your cascade ovens).

I don’t recall their customer service (2014-15?), I just needed the thing. which in this case was was a pair of odd size round silicone heating pads (12-ish in)…possibly (probably ![]() ) pushing power density limits. Press was never put into service because “flower rosin” was where folks were back then…and it was simply not commercially viable (even with a bigger press).

) pushing power density limits. Press was never put into service because “flower rosin” was where folks were back then…and it was simply not commercially viable (even with a bigger press).

I also used their cartridge heaters in the smaller press that we used to make the “yeah, this is silly…” decision.

Did you find what you needed @Hippymeds?

Care to share where?

(I’d like to know why too…![]() )

)

In case you haven’t, and my guess at your use case was close, the “cooling table” we snagged is surplus to our needs at this point…

The cooling table would be right up my alley… how much? We need it to cool our matts quickly. No need to heat your matts, if you’ve done your homework.

@Hippymeds i know you’ve reached out in the past. When you are ready to pull the trigger, hit me up.

It’s stupidly heavy…shipping may be expensive.

Looking at your pics… there is no need to buy it…lol

I know how to sweat copper and tack weld steel…

New project added to the list! I definitely see a few improvements that would help efficiency.

I helped him he ended up just needing to cook out less water and he got the gel time he needed

If youre looking for custom heat pads and such ive used

Keenovo Flexible Heater Store

Lemme see if i can find there website

Ive had great success with them, they made me custom heating pads for the reducer on the feed flask i made there production time, ship time, price and customer service was great

Hey brother. I sent you a text asking if I could buy samples of the 3 kinds of gummies your sops will make. Also still would love to know your silicone mold selection and prices. I didn’t know if you saw that.

Hit me up in 2 weeks (6-12-25). We will be done with our current CBD gummy contract by that date. Ill have approximately 2.5 weeks untill we start our next contract. Use my personal number I sent you. It will be awhile untill im free again. We are increasing production by 100%. And I’m already pressed for time.