Yeah by the way more faceted stones! Damn things look cut by jeweler

If you “blast” any gas through a tube of herb you will take the volatile’s with it, how well and efficient depends on the side variables and parameters such as temps, pressures, velocity etc.

The easier part is removing them, the harder part is collecting them. As you well know, in order to liquify or solidify the now gaseous aromatic fraction we need to cool it down to collect it. According to the good folks at labconco( How to select the correct Cold Trap - Labconco ) you want your cold trap to be as cold as the substances lowest melting point, which is variable, but fwiw limonene’s is -76c’ish and according to that labconco article if using dry ice/iso or acetone might only capture 80%ish of the limonene, obviously depending on the cold trap efficiency. Remember thats a 1atm, if using a vacuum to assist in extraction you lower the melting points as well as the boilings.

If he’s using only butane to extract pure clear terps that’d be my guess, perhaps there is a benefit of using butane over other inert gasses Im not sure.

Check out thetetraguys art: https://future4200.com/uploads/default/optimized/3X/4/f/4f430bc77553ad663bf6cd20e011ae5fea477697_2_666x500.jpeg

Yes i believe the added pressure of nitrogen on top of butane would force it back into solution, though Im not positive about it, or know how much pressure would be required. This would effect the saturation but remember the liquid to gas expansion rate of butane(I dont remember it) but its very roughly probably something like 4000:1 so if you had 1 liter of head space how much possible liquid tane is available to be manipulated back into solution? a couple ml’s? How much added pressure to accomplish that, pressures can be controlled safely but In my mind why go over the “natural” pressures to accomplish a little saturation adjustment vs changing the temp or solvent amount?

I could see a big benefit being that butane is easily condensible and inert isnt, so could keep adding it to a closed system without added pressure.

Okay I think I’m finally understanding! Thanks for hanging with me and allowing me to process my thoughts. It’s important to note while I’ve been blasting a long time, it’s been even longer since I took chemistry at the university lol. Temperature and pressure effect the solubility of the solute within the solution. I think my problem is I’ve been thinking of a way to vent the miner in order to manipulate saturation levels. Sound like I just need to work with temp… know a good range to start and manipulate that variable.

Recently we had a batch of “failed” diamond sauce, no nucleation. I assume I just had wayyy to much tane in it. I played it too much like the jar tek “wetter is better” but since there was no ability for the miner to “vent” it just set as tane soup and when it got burped it was too much to fast.

Anyways this has given me a lot more to think about and ways to hopefully improve our process. We do have a ton of system upgrades in progress so I’m hoping as we implement better practices along side improved equipment the results will greatly improve

I was way off on the expansion ratio, its only 233:1 so a bigger factor than I presumed.

If it was low in viscosity and stalled its undersaturated so like said you can vent it to reduce the solvent, or you could have also reduced the temp to reduce the solubility.

Seeds can help find the sweet spot, toss em in and watch if the dissolve or not, if they dont get smaller they will usually get larger, and if they stall out lower the temps slightly, if the dissolve lower the temps largely or reduce solvent amount.

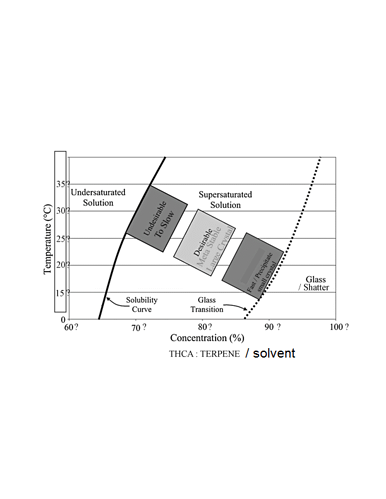

Heres a couple charts I like to share:

I’ve been curious if anyone has tried any of these methods with a closed column, but I think this is the first time I’ve seen anyone refer to one specifically. I think I might give this SOP (not the strong sauce) a shot with the set up if have available and see what happens; and if I can get that sugary-like end result.

Should I be doing this with 100% ntane though, or can I get away with using a 70/30 mix?

By the way I like the Pyrex in the measuring cup for easy pouring.

Everyone I know who’s bought miners went back to jars ![]()

Old school right there, a open jacket column w a closed column… Will work fine but if you don’t over cool your solvent or it won’t go in it.

Comes out like thick gel w live I was so cold. Don’t do this stuff inside though

Yeah my home set up is still being upgraded. My original column was one of the first jacketed ones. It was the last set of open blast tubes subzero scientific sold. From there I added a spool extender from BVv, switched to high pressure clamps. On the next upgrade I got the 24 inch jacketed closed column. Problem is it fucking talllll. So I just got some more end caps, ball valves, hoses and I’ll go rack mounted and the dewax will go next to the material column instead of under it. Hoping to talk to killa123456 next for a collection pot and I can finally be fully closed loop!

Good point with the solvent. I normally chilled the column and material for a while vac it down fill it with frozen cans then use a room temperature can for the last “push” to offer a higher pressure and ensure a good fill. Definitely ready to be done with this style of blasting though!

Not advocating it, but you can do anything with open blast that you can do with a CLS, except recover the solvent.

You can dewax in a gallon jar in dry ice.

You could add a crc to your column

You can make diamonds

I use to think the same thing BUT

-

You can’t have no fuems w open blast.

-

You can’t push dry ice cold solvent that’s so cold it WON’T move without nitrogen boost without the loop.

-

You can’t distill your gas.

-

You can’t true closed 2nd stage in vessel dewax

-

Most likely youd have hard time running full CRC.

-

Did I mention it’s safer? Well to most ppl at least

-

I think I can keep going on the advantages of a CLS other than Just recovering tbh

There’s way more I use to think the same thing though

Im not saying you’re wrong, you’re definitely right. You can do just about anything if you have the right setup and know your tech. @StoneD definitely has a few valid points though; and they’re all things that I have thought about myself. It does go slightly deeper than just not being able to recover your solvent.

The biggest point though is the variance in the SOPs between the two (CSL and CC) obviously not the exact same; but similar to extent. Either way, still not commonly being done because people who are doing this are mostly running larger batches on more advanced machinery.

That’s awesome. Sounds like a decent little set up. I would love to set mine up to be a complete closed loop as well but I’ve been thinking about if it’d Just be more worth it to just get a whole new 1lb cls instead.

Either way, I hope you continue to share your jar experiments with the closed column as will I. Still deciding if I want to wait until tomorrow to get ntane as I only have 70/30 right now, but I guess we’ll see.

In a 500ml mason jar, what is the volume you would like to have of mother liquid in order to get bigger facets? eg; Fuller = bigger?

So like if you had 4 x 500ml jars of solvent rich liquid and reduced them to say 100ml then, take the 4x 100ml of reduced liquid put it into one jar to make 400ml of high terp high THCA “mother” liquid, would that allow a larger facet ti grow, obviously keeping within the temp pressure requirements?

I use 40/40/20 n iso pro.

Will this work for growing diamonds?

Open blast 2 oz cured nug run thin mint cookies.

This run was just a quick blast into jar and cap but…

I could dewax better than anyone via open blast.

I cannot safely crc using cans but I could open blast crc using a closed column

SIze jar you blasted into? or should I say what size jar did you fill with 60g material?

Blast into the biggest jar you can, reduce volume until the oil barely starts to stick to the jar, then swirl solution around to dissolve that oil, and pour into smallest jar you can. Fill jars no more than 75%