Hello all. I recently took a position to learn and run an ethonal bath system, rotovap, and reactor setup. I have received very minimal common sense training, and don’t really have skilled overhead regarding this process. I have a good opportunity if I can make this work, so I have decided to reach out to this group. HERES THE ISSUE I AM FACING: WHEN I STARTED WE HAD AN AGILENT DRY SCROLL PUMP. IT WORKED FINE UNTIL A FILTER IN THE BATH CLOGGED. BY THE TIME I FIGURED

OUT WHAT WAS GOING ON THE PUMP SUCKED ETHO INTO ITSELF. THAT PUMP WENT TO THE SHOP. I WAS ADVISED TO TAKE THE EDWARDS 30 FROM MY DISTILLATE STATION AND USE THAT. IT WORKED FOR A WHILE, VERY LOUD WHEN DROPPING PRESSURE DURING THE PROCESS. RECENTLY IT JUST STARTED SHUTTING Down BUT STILL RUNNING, JUST NO PRESSURE. my question to you all is what am I doing wrong? Do I need the agilent pump back? Could the Edwards 30 pump not be ideal for this application? Am I just a cancer to vacuum pumps?? I know my equipment may be outdated, this lab hasn’t been running since 2019, but this is what I have to work with. Please help!!!

Are you asking if the Edwards can be used on a roto? I definitely wouldn’t recommend it.

I second this lol. Go buy a cheap harbor freight pump and add an additional cold trap just before the pump and you’re good. Make sure to get the warranty too. Then when it shits out on ya you just take it back in exchange for a new one. But in all honesty. I’ve put them things through hell and back. And am yet to kill one. Had one seize once. Got bored and wanted to know what was going on inside a vacuum pump so I tore into it. It still puts in work.

Getting your vacuum pumps drunk is bad for them…

This thread is a reasonable exploration: I just got a 2L rotovap, will this vacuum pump work with it ?

…and because most reading that thread won’t go see why hooking a jet engine to a Rotovap is not a great idea… it turns out drunk pumps can become belligerent too…

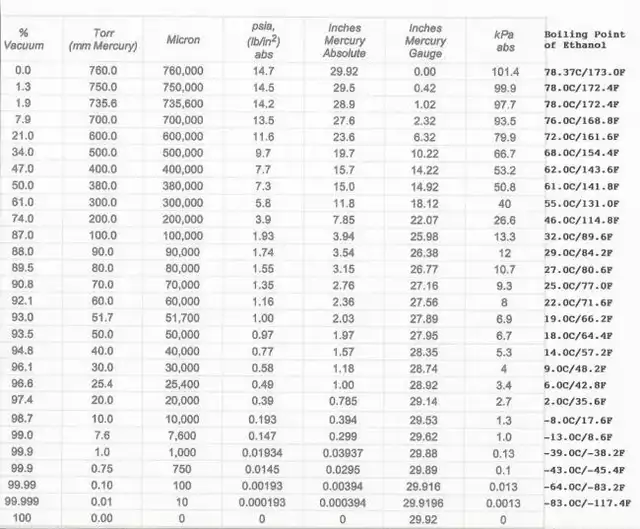

Wrapping your head around this chart is also helpful. It should explain why you needed a cold trap in front of the pumps you were using.

Any rotary vane no matter how expensive will need a cold trap to condense the alcohol before it ever reaches the pump. No matter how you do it though, there will always be the possibility of alcohol or chemicals going into the rotary vane vacuum pump. If you decide to keep going rotary vane, you’ll want to use a needle nose valve to control the vacuum, a gauge to manage the vacuum, a cold trap and you’ll want a oil mist filter for the pump so the pump isn’t spewing oil mist vapors.

Chemical Resistant Diaphragm Vacuum Pumps are what you need to make a rotovap work for you.

You could get a regular non chemical resistant diaphragm vacuum pump and run a cold trap but diaphragm vacuum pumps just spit out what they don’t like and don’t get (as) drunk.

I have 2 cold traps and 2 stage rotary pump, and I change my oil after a run or two. Even with cold traps vapors get by and get into pump.

If you could put that pump on a vfd, you can control its speed so you don’t suck too hard. We’ve used them to control ethanol FFEs. They would only turn a few times a minute to keep an appropriate vac level. Running full speed, you’re bound to put a significant amount of ethanol vapor in the pump, even if you’re using liquid nitrogen in your cold traps.

I have worked with VFD’s but never considered using one to moderate vacuum level, that is cool as shit! Definitely wanna play with that! Can you run the VFD real low or is there an acceptable range?

This is what I use for most vacuum applications in my lab. That includes my 5L roto, sucking down my reactor and other vessels and general suckery. It works well, and if you plumb the exhaust out of the building, you won’t even need a cold trap (if you’re into that). I run a cold trap anyways, though…

They are great little chemical rated pumps that are still cheaper on the used market than a brand new Hazzard Fart rotary vane.

I’d grab a bigger one with more pumping heads if you can afford it, though. I’m starting to outgrow ours.

You can run them at super low RPMs. With automation programming, you can control turbos, roots, and rotary vane pumps to keep a precise vacuum level in a wiper or FFE.

That would’ve been WAY smarter to do than rapidly plugging and unplugging my Alcatel to pull the residual solvent off in my SPD. Gotta have Johnny FastHands to keep it from bumping all the way through! Thanks for the spoon, brother! ![]()

So I know that you can “overdrive” motors with a VFD and +10% is usually not detrimental to the motor life, but would that apply to vac pumps as well? Could you make em suck harder by driving them at say 70 or 80hz?

This is potentially damaging advice without acknowledging some stipulations/caveats

Firstly is that your vac pump has to be able to handle low RPMs. For a roots type this probably isn’t a problem but anything with a lubricant pump instead of splash lubrication it can be

Torque falls off the further you get from 50-60 Hz. At the low end, voltage does too thanks to the V/F curve.

Most vac pumps I’ve seen fan is spun directly on the back of the motor. Go too slow and your motor may not spin fast enough to move heat away from it, which can trash your motor windings and kill it. Easy enough to fix with a separate, constant speed fan but something to be aware of.

Also motor has to be 3 phase in order to manipulate speed with a VFD. Most “speed controllers” intended for use on 120V equipment like routers and fans is just a phase angle controller, frequency stays at 60 Hz the motor being driven just doesn’t see all of the AC sinewave curve

Personally I like dry, chemical resistant pumps better but we all gotta start somewhere.

Look for 1000:1 turndown / Inverter Duty motors if you want to regularly use them at low frequencies.

You can frequently turn decent quality motors up a fair bit more than 10% from 60Hz, but this is one of those “if you have to ask if it’s ok you probably shouldn’t” situations, because you have to know how to read the motor data sheet and what is important and relevant to that type of duty cycle.

And

The pump you linked is twice the price of the pump I linked, and is not chemical rated. The chemical rated Vacuubrand pumps don’t technically need a cold trap if you don’t care about recovering the last bit of solvent and you can safely exhaust it from your lab… just some food for thought.

Vacuubrand makes a diaphragm pump with a controller on it that will take out all of your questions about bumping and will help you reach optimal vacuum speed. It’s an awesome controller which you can buy separately if you wish to.

I’ve got a jkem vac controller that I bought but never really used because I got better at throttling the vac with the pump. I feel like it would definitely help the noobs, though.

Is going to be my next suggestion if op is looking for a small setup chemical resistant one.

/ is the pump is use on my 5L

I have no idea what anyone uses large scale. I’m a 5L rotovap user when I make rso so other than that … OP is gonna have to listen to someone who has more experience with a bigger roto.

I don’t think OP even stated what size their roto is.