The critical temp is 31 C, so you just need to dip below that.

Will definitely be a challenge but I think I can swing that with some machine manipulation, can’t wait to experiment and post the results! Won’t be for a bit, we’re really hot on reintroducing CDTs to some pens so the higher ups don’t have THAT much interest in it outside of maybe getting some more desirable terpenes from the FF itself but i’m gonna be pushing for them to throw me a bone ![]()

Try 1250psi and 20C for decarbed material, and put some terps back in it

I’ve actually used those parameters to make some really nice oil! The problem was that it popped hot for residuals just like my terps! Really really frustrating considering how great the oil itself smelled and with the reintroduction of terps would have been something really tasty I think ![]()

I suspect you ought vet your 3rd party lab some more.

It’s possible the one that gave you that result is only using GC FID headspace to do the ID and actually has no clue what they are actually seeing.

Try submitting that latest sample to multiple labs. at least 3x. Make sure you don’t Thaler them know what you’re up to until you’re done.

Sit down and chat with the director at whichever shop does “best” in your opinion. (Best agreement with each other might be the right metric).

If you have a solvent issue, dig into it. If it’s a lab issue, reproducible is often the best bet.

Short answer : Cost feasible, no. Scientifically feasible, yes. ![]()

We’ll see…

Effect of color correction using CR2.

Left is untreated. Same strain extracted of roughly year old flower.

Consistency of THCA fraction; turn up the volume and hear the crystals clank…

samples headed for third party lab analysis this week likely

I have made CO2 wax, honeycomb, shatter and Isolate using nothing but CO2, but the process is Slower than the hydrocarbon / alkanes / alcohols. the process can be done at the same speed, but the asset cost is significantly (with an ,) more expensive, so unless you have a super custy willing to pay 2-3x for Solvent less Shatter / Isolate / wax IE $40-60 for CO2 wax / shatter vs $20-40 for traditional solvent wax/shatter your not goin to find it profitable.

why spend more for equipment only to produce extracts with 2x COGs? well because sustainability.

I don’t know what other people’s process is or what their costs are, so I won’t comment on the profitability of their operations. CO2 is, in theory, finely tunable to produce fractions that can be turned into products with little to no processing. I think I can dial in an SOP to turn one of those fractions into a profitable product that I would myself consume, even from year old flower.

Is it a turn-key option to a profitable lab? Fuck no. But the incorporation of THCA products in addition to disty (vapes/gummies) can add valuable SKUs to your shelf. If you spent the $$$ on nice extraction equipment might as well take it for a spin on the track every once in a while.

Still dialing in the formulation ratios. I added another 10% THCA crude after this video iirc.

Super interesting, I appreciate you sharing!

CO2’s something I may never get to play with, so I appreciate the little teasers.

looking gorgeous!

As someone who has worked with CO2 quite a lot, I am a bit concerned about the fat content of these extracts. I would be interested to see what the terpene COA for these extracts would look like, but to me, these extracts look to be loaded with wax.

Definitely not comparable to anything extracted with hydrocarbons when talking about terpene quality and extract clarity, and to get better yields/fractions, the amount of time added to each run is quite a lot.

$0.02

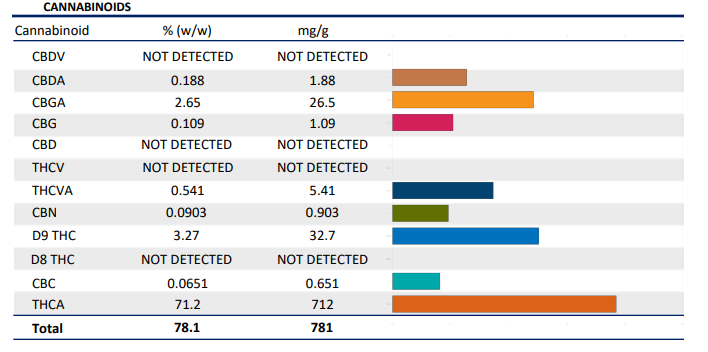

The crude CoA is above, as are pics of it. The crude has close to 78% TAC, so it’s definitely not “loaded with wax”.

Testing will include terpene profiles. Final mix ratio was ~84% THCA crude to ~16% refined terpenes.

I was concerned about the possibility of high wax content until I saw the analysis for the crude. 3 succcessive batches, all similar consistency.

But, all in all, I have about 4 weeks R&D into this including only 5 runs so far with color correction. This is a work in progress, but I consider it substantial enough to offer it for sampling/review by employees. They will determine whether it goes to market or not at the current time.

sweet. this dewaxing run is a good idea. Terps, dewax, then hammer? and get the goods. I have had some luck in supercritical ranges when trying to dial in a similar process but would pull waxes at the 4hr mark then not at 6 then more at 8… really throwing me off.