Hey everyone,

long time lurker, first time poster  I just wanted to ask everyone about their opinions on the idea of making waxes, shatters and more with CO2 extraction. I’ve explored a bit on here about CO2 extraction and have come across some shatters people have made, a live resin, actual THCa crystallization and I believe maybe one with a batter like consistency as well. Do you think this is a feasible process that will take hold in the future? To my understanding one of the main issues you’ll run into attempting creating these products is pulling water into your slurry since you wouldn’t be decarbing your starting material to ensure it’s thoroughly dried, i’ve ran into this doing terpene pulls, on top of this your run time for this would increase dramatically correct? I’ve been running CO2 extraction for about a year and half now making your basic oil/distillate slurries but have also messed around with some terpene pulls and subcritical runs to create some really beautiful fragrant oil that can go straight into a cartridge and am getting ready to start some more R&D on more stable concentrates out of CO2 extraction. Is it wrong to assume that the post processing for these products would be the same procedures as with BHO to create the desired end product? Sorry if this is confusing it’s early and I haven’t had my caffeine yet

I just wanted to ask everyone about their opinions on the idea of making waxes, shatters and more with CO2 extraction. I’ve explored a bit on here about CO2 extraction and have come across some shatters people have made, a live resin, actual THCa crystallization and I believe maybe one with a batter like consistency as well. Do you think this is a feasible process that will take hold in the future? To my understanding one of the main issues you’ll run into attempting creating these products is pulling water into your slurry since you wouldn’t be decarbing your starting material to ensure it’s thoroughly dried, i’ve ran into this doing terpene pulls, on top of this your run time for this would increase dramatically correct? I’ve been running CO2 extraction for about a year and half now making your basic oil/distillate slurries but have also messed around with some terpene pulls and subcritical runs to create some really beautiful fragrant oil that can go straight into a cartridge and am getting ready to start some more R&D on more stable concentrates out of CO2 extraction. Is it wrong to assume that the post processing for these products would be the same procedures as with BHO to create the desired end product? Sorry if this is confusing it’s early and I haven’t had my caffeine yet

Anyways thanks for all the sweet information I’ve mined from this community so far! Can’t wait to be able to contribute my own little chunks of knowledge as time passes by and I learn more

4 Likes

It’s possible, but with current extractors yields will be ultra low, because you need to extract THCA and not THC. CO2 is far less efficient at THCA extractions. Essentially you will be scraping crystals off of the sides of your recovery chamber, and then melting it down in a vacuum oven to make your shatter.

2 Likes

Yeah that makes sense for sure, but granted you really wanted to and could afford to put the time and resources into it do you believe a fire product could be produced that could compete with a BHO extracted product? I’ve never smoked anything from CO2 that wasn’t either oil or distillate obvs, but theoretically I could see being able to make a really tasty wax by running for a long time at borderline sub/supercrit. Obviously this wouldn’t be efficient at all especially compared to BHO extraction. Also if you were able to heat your recovery chamber enough wouldn’t the majority of the extract melt down into the cup? I’ll definitely be keeping this updated with what I find when I get into it though. For science!

Can it be done? Almost certainly.

Can it compete in the market place?

Probably not.

Unless the rules change.

…they might.

That certainly seems to be the bet many folks running CO2 are making.

5 Likes

It seems like this is mainly going to be for the markets where BHO or anything like it is highly restricted and basically impossible to have, definitely just thinking and trying for whatever may happen in the future. Always nice to be ahead of the market in that sense if you’re able to sacrifice the resources for it I’d say

2 Likes

You can also get most of those sku’s from squish…

Chromatography on the other hand.

I would love to do some solventless R&D in that sense as well! Do you think it’s more efficient though? Cheaper in terms of actual machinery definitely but from what I understand the yield for squishing is abysmal as well? And Chromatography is something i’ll definitely need to look into a bit more now

I’m thinking a combination of THCA from rosin and terps from subcritical would make a tasty and affordable dab…

2 Likes

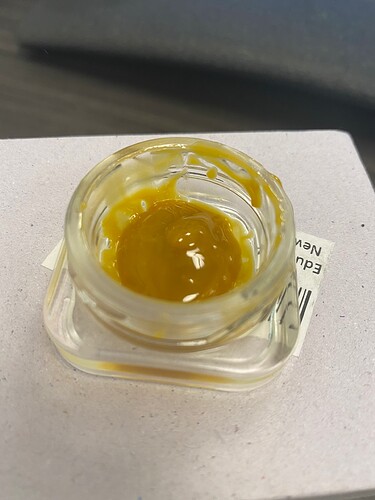

I’ve been doing R&D runs for a week and I have to say I think we will be going forward with some CO2 batters.

This is an unwinterized cannabinoid fraction combined with a refined terpene fraction. Both run at sub-critical parameters. All CO2.

7 Likes

As someone that’s never run CO2, what made you chose it?

1 Like

You dance with who brung you.

I was hired to do vape pens and gummies, we went through a corporate merger and the new bosses are all about the concentrates. Our facility was set up with only CO2 and the local jurisdiction has a ban on hydrocarbon extraction permitting.

2 Likes

That so true, I didn’t really consider it. I’m lucky to play with my solvent of choice, but it looks like a fine product through a different path.

1 Like

The new bosses are talking about another shop with C1D1 capabilities, I’d love that, but until then this is what I have. Happy to be pushing the boundaries of what the equipment can produce.

1 Like

First runs looked straight up like baby shit. Lol. Im running some CR2 for color correction and dialing in a dewax run between the terp and cannabinoid runs. Glad its looking more marketable.

3 Likes

Badder often seems to run the line from applesauce to baby shit in appearance, lol

a friend called it “meconium kush”

3 Likes

I was pleasantly surprised and satisfied with the CR2 media and also just being able to throw it in at the bottom of the extraction columns.

Nice, I would have loved to try this 3 fraction extraction when I was still with my old company

I would smoke it! Sounds like you’re doing some really cool stuff! Right now we’re barely messing around with doing terpene pulls to reintroduce into cartridges for our R&D but we’re very curious to see how fresh frozen material will run and the post processing issues that come along with it. Did you do decarb for the unwinterized cannabinoid fraction?

No decarb. We were gunning for THCA.

Honestly it is going to depend on your system as to whether you will be able to get away with THCA over THC. You need the solvent density that higher pressure gives you, so you really need to get over 2500 psi to get the yield that makes it worthwhile due to the decreased solubility of THCA over THC.

This is from old cured flower as well, I’d love to get a freeze drier and take a swing at some pseudo fresh frozen.

2 Likes

Jeeeezeee I can’t wait to see what you can do with some pseudo fresh frozen stuff! You must be running hella cold if you’re running subcrit parameters at >2500psi, our machine definitely has the capability to reach those levels of pressure but keeping it cooled would be the hard part I believe. Can’t wait to mess around myself.

1 Like

![]() I just wanted to ask everyone about their opinions on the idea of making waxes, shatters and more with CO2 extraction. I’ve explored a bit on here about CO2 extraction and have come across some shatters people have made, a live resin, actual THCa crystallization and I believe maybe one with a batter like consistency as well. Do you think this is a feasible process that will take hold in the future? To my understanding one of the main issues you’ll run into attempting creating these products is pulling water into your slurry since you wouldn’t be decarbing your starting material to ensure it’s thoroughly dried, i’ve ran into this doing terpene pulls, on top of this your run time for this would increase dramatically correct? I’ve been running CO2 extraction for about a year and half now making your basic oil/distillate slurries but have also messed around with some terpene pulls and subcritical runs to create some really beautiful fragrant oil that can go straight into a cartridge and am getting ready to start some more R&D on more stable concentrates out of CO2 extraction. Is it wrong to assume that the post processing for these products would be the same procedures as with BHO to create the desired end product? Sorry if this is confusing it’s early and I haven’t had my caffeine yet

I just wanted to ask everyone about their opinions on the idea of making waxes, shatters and more with CO2 extraction. I’ve explored a bit on here about CO2 extraction and have come across some shatters people have made, a live resin, actual THCa crystallization and I believe maybe one with a batter like consistency as well. Do you think this is a feasible process that will take hold in the future? To my understanding one of the main issues you’ll run into attempting creating these products is pulling water into your slurry since you wouldn’t be decarbing your starting material to ensure it’s thoroughly dried, i’ve ran into this doing terpene pulls, on top of this your run time for this would increase dramatically correct? I’ve been running CO2 extraction for about a year and half now making your basic oil/distillate slurries but have also messed around with some terpene pulls and subcritical runs to create some really beautiful fragrant oil that can go straight into a cartridge and am getting ready to start some more R&D on more stable concentrates out of CO2 extraction. Is it wrong to assume that the post processing for these products would be the same procedures as with BHO to create the desired end product? Sorry if this is confusing it’s early and I haven’t had my caffeine yet ![]()

![]()