Sup guys, I’ve been working in a CO2 lab the last year and haven’t seen too many terps from CO2 extraction on here so I figured I’d share some of what we do. We pull some pretty nice terps, although they’re different than bho terps I have come to enjoy them more and more. If anyone else has any terps they want to share (co2 or bho) post 'em up!

What system are you running?

We’re running Apeks machines.

Can’t say I’ve tried C02 terps, how are they compared to bho? I like the colors and viscosity

They have a different, edge I guess you could call it. When blended with distillate and put into carts/pods it’s very tasty. strain/material dependent of course.

These co2 Terps look amazing on apeks,

im currently on ies machines and trying to find that perfect density!

1180 psi, 42 C…. 290 kg/m^3 density

Density range of 270 - 320 kg/m^3 is optimal

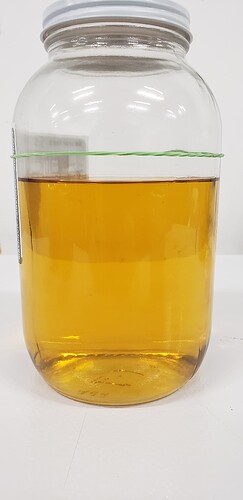

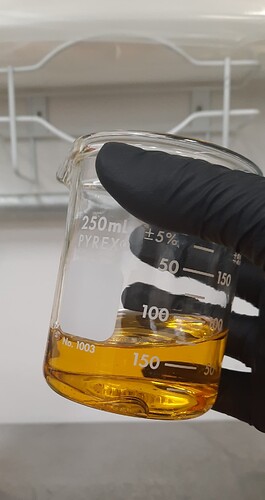

Some recent work from this week. All different strains from the same farm. They came out stellar color and have a great nose on them.

@Betroit @outdoorphil

Terps looking good, I have some questions for both of you, if you’ll entertain them. Are these terpenes cleaned up at all? Any kind of distillation being done?

Have been warry about co2 terps because they always seem to have grassy smell, trying to remediate that if possible. Any distillation going on? Filtration or washing?

Interested in your thoughts, I’m on the hunt for someone who can pull non-grassy co2 terps, or who can remediate out the grassy component.

The pics I posted of raw CO2 extracted terpenes are not distilled.

Yes they can be filtered. Yes they can be refined. Which we do. I also posted a pic of water clear terps after refinement. Grassy terps sounds like steam still or poor quality initial biomass

These parameters are not necessarily applicable to an IES system for achieving the same results as OP.

Those are supercritical/near critical parameters and seem ideal for Apeks systems as they utilize a gas diaphragm pump and one or more orifice caps to separate in multiple separators.

It is easier to run IES, MRX, and Edens at sub-critical parameters and get a sauce than run it near critical or super critical and expect to be able to fraction/separate terpenes from cannabinoids.

I run a density of 800-940 kg/m^3 and typically get a sauce that is 20-50% terpenes and 15-50% cannabinoids. No visible lipids with bud-only runs and ideally below certain pressures.

This is what I used precisely on an IES.

From my experience, that was not the case, Super critical always worked for me to fraction off and isolate various compounds.

Fractioning terpenes with the 290 kg/m^3 followed by fractioning the cannabinoids with parameters giving density of 820 to 850 kg/m^3 always gave me isolated factions under supercritical conditions.

There is nothing wrong with the density that you are using, although it is geared towards pulling out cannabinoids and other heavier compounds. This is why you do not have an isolated fraction of just terpenes. With liquid CO2/sub critical parameters, the pulls are a great full spectrum extract, just not an isolated fraction. In fact, under subcritical/liquid CO2 conditions, you cannot adjust the Temp and Pressure to isolate terpenes only, you will always pull cannabinoids with it. Nothing wrong if you are going for the

Are u using a solvent? Don’t have to tell us which one

Here are some CO2 terps we pulled from lifter hemp grown in the 2021 season. This is the extract as it comes out of the machine, before post processing including water removal.

We are definitely going for sauce, but I will have to play with supercritical ranges again for terpene isolation. It may just not be feasible with a modified machine built in 2014/2015 from copied designs. Reluctant to do the trials again as I do not have as much throw away material to experiment with.

What kind of separators and pressure reduction devices are you utilizing on your IES to achieve that separation in the supercritical range?

I’ve been running self-modified MRXs for years. Single separator column (there is a second separator in tandem with the 1st, but it operates more as a cold trap than anything else) fed by a Whitey needle valve attached to a hanbay actuator. Automation is fine for supercritical runs but sub-critical is all manual. Unfortunately MRXs were just copies of copies.

Yeah these were separated using a multi solvent gradient that includes polar and non polar