BP is -11F, pretty easy to purge if you like it like dat.

Where did you see stuff on the burned gas? I can’t find it anywhere, all I can find is research comparing the combustion byproducts to diesel and propane for internal combustion engines and it seems a lot cleaner than both of those.

Generally recognized as safe PDFs from the FDA on DME

https://www.accessdata.fda.gov/scripts/fdcc/?set=GRASNotices&id=741

https://www.accessdata.fda.gov/scripts/fdcc/index.cfm?set=GRASNotices&id=695

This is PDF with the extraction description and residue testing.

You know it’s funny you ask. I sifted through a bunch of info and can’t find that specific bit of source now. Gimme a bit.

I really appreciate it!

So hot the banger is red hot and u dropp the dab inside and it goes POOF and shoots a flame outta the top… Only that hot right

Red means go?

That was joke

I don’t hear mine to red unless I’m cleaning it…I barely get it hot enough that if it didn’t have carb cap it wouldn’t smoke!

Thank you for the reg data! I appreciate!

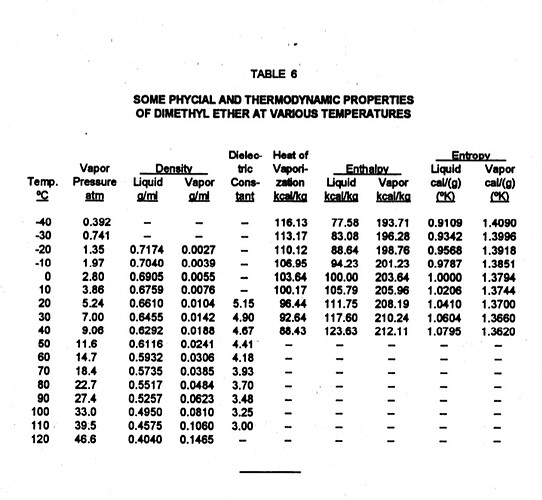

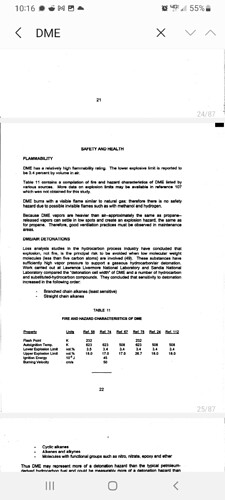

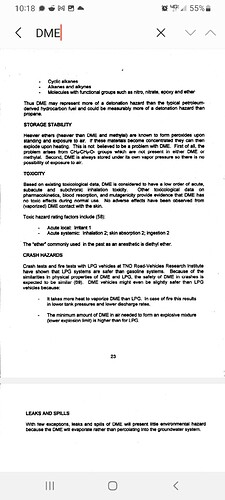

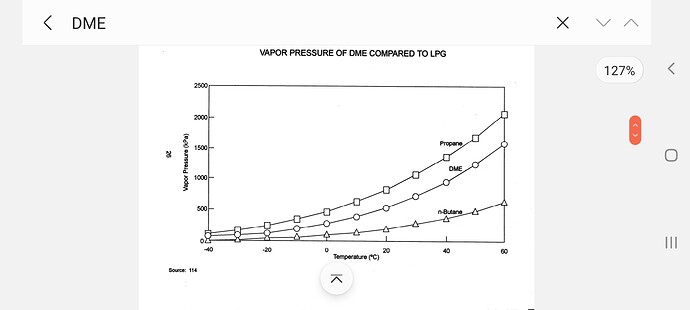

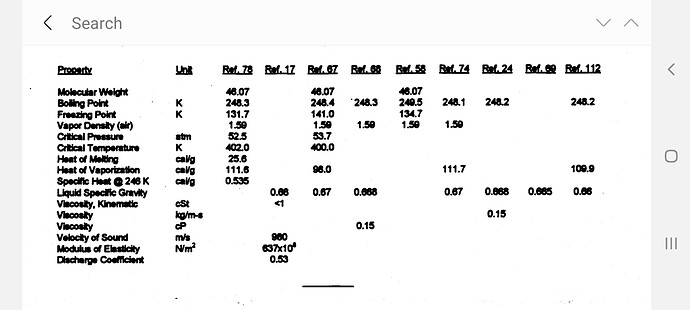

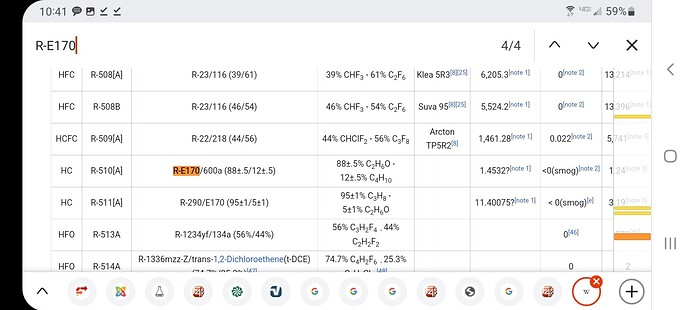

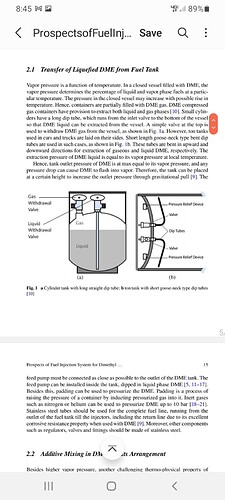

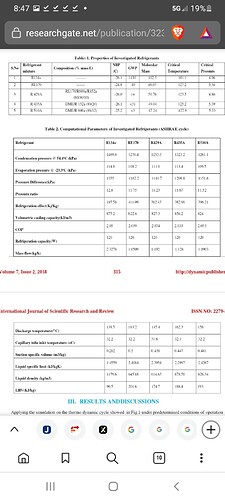

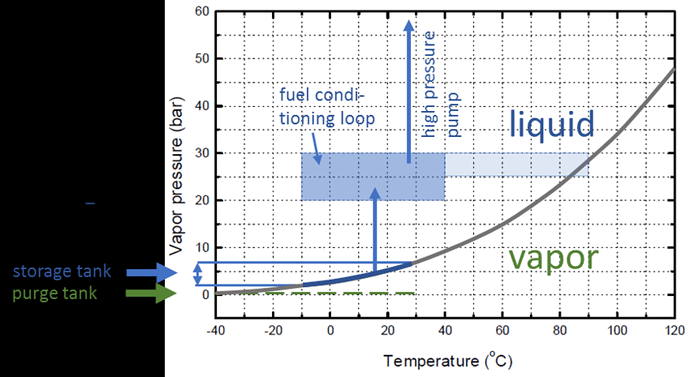

Thermodynamic data for DME, tank design, research on peroxide (spoiler: it doesn’t make peroxides) formation, comparison of vapor pressure between butane, propane, & DME, and azeotropic mixtures of the three.

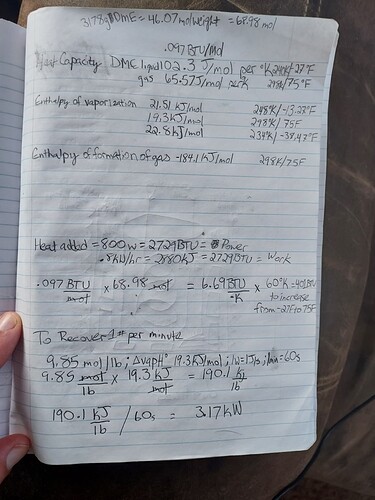

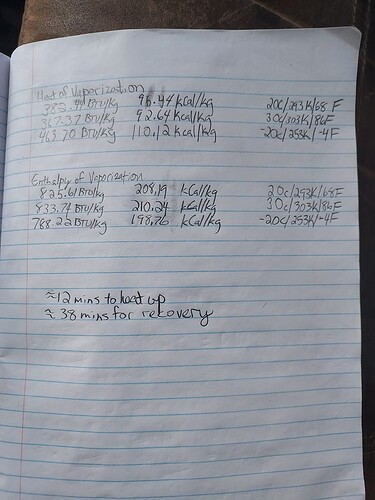

Recovery calculations, I believe the heat needed to vaporize DME at a rate of 1 lb per minute is 3,170w.

Using my 800w sous vide heater I should recover at a rate of 1 lb per 4 minutes at 100% heat transfer efficiency. At 75% transfer efficiency I should recover a pound of DME every 5 minutes 20 seconds.

I took the equations posted by @TheGratefulPhil and filled in the DME data. This site has some really detailed technical information if you know what to search for!

My next addition to this system is going to be making 2x DIY 8k BTU glycol chiller loops that are cooling 2x plate heat exchangers. I’ve got dual recovery lines, so I’m going to put a plate exchanger on both lines. I know it won’t condense in the plate exchanger, but it should remove most of the heat energy before it goes into the tank, so my dry ice lasts longer. I’ve got to drive an hour each way to get dry ice, so I want to make it last.

@Rowan do you think I would be better putting both ACs in a single glycol bath or use a separate bath for each chiller? I saw your thread on making them, it was an excellent read!

Hell yeah dude way to thermodynamics!

Dimethyl ether or dimethoxyethane?

Thanks! I found so many of your posts when I was doing my thermodynamics research, technical search terminology is a direct line to your posts. You listed it all too, even the matching dry ice sublimation rates (which I’m fairly certain was 5g/s) for 1lb/min n-but.

Hopefully I got everything right, because this is the first time I’ve seen these calculations for dimethyl ether.

Dimethyl ether

If you’re gonna build the chiller yourself you can make it easier by using a minisplit instead of ac units.

Unfortunately I don’t have a mini-split, but I do have 6 extra 8,000 BTU window units from when I was running multiple grow houses.

Once I find a competent and discreet HVAC tech in CO I’m going to have the evaporator cut off these units and pump the refrigerant directly into the plate heat exchangers. The plate heat exchangers I’m looking at from AlfaLaval are able to run even with higher pressure refrigerants like r410a, hell they can even run CO2 as a refrigerant with their tolerance, but I’m not sure of the best refrigerant choice for this project tbh, which is why I want to employ a tech.

Tuffsteel sucks for the sell-your-firstborn price, try Glyon.

Here’s some information I found useful on plate exchangers.

Dry-All-Brazed-Plate-Heat-Exchanger-2020.pdf (2.6 MB)

alfa-laval-alfanova-range.pdf (444.9 KB)