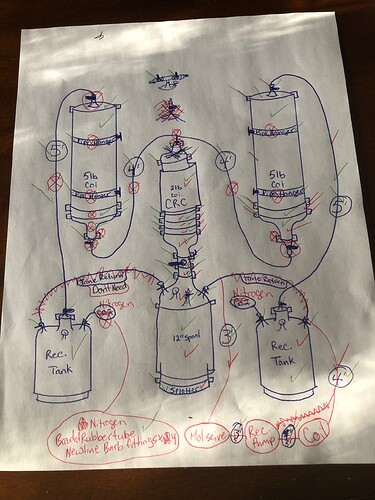

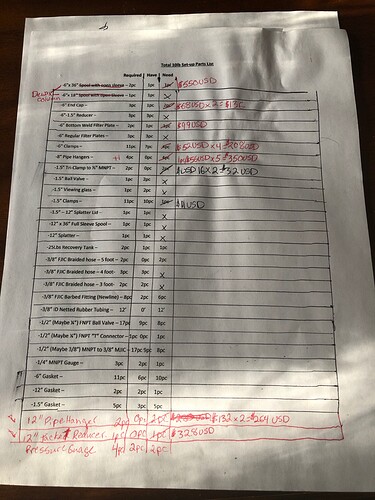

Hey y’all! Back at it for you people to tell me how dangerous my situation is. Jk. I’m not looking for the dangers. I know full well what I need to improve to make it proper and more inline with C1D1 room. What I seek is opinions or guidance on how to double my material capacity per run, while minimizing new parts, and maximizing safety on the cls alone. I see two routes to go from 5lb runs to 10lb runs. One is as the picture I will include depicts. And the other route would be to just get a 10lb column. But finding a ten lb column is seeming to be a bit of a goose chase. 10lb column would reduce parts to buy and or to fail, but twin 5 lb columns I would imagine would be a more complete extraction from the material. Then if I were to go twin 5’s would I want to get 6” end caps with twin ports for top of material columns/spools? One for liquid butane in and the other to connect the two material columns at the top to maintain equal pressure between the two, with the nitrogen push on the solvent tanks coming from one regulator/tank. I often see similarities between cls and espresso machine. Just switch coffee for flower and steam to solvent and super size. Either route I take I plan to rack mount and make a containment cabinet vented outside with in and out flow with explosion proof fans for the cls to operate within, with doors on the front for access, I’m thinking. Opinions?

Those crates are scaring me. Have you seen the crate challenge on whatever TikTok or YouTube wherever it was hosted? That’s one butt bump away from a really bad time.

I can’t tell you how many things I have to just push through the fear and make it work and minimize bottle neck of the lab from the material in and sales out. I’ve truly had to push through to make it work, triaging/mitigating what I can as I can till I’m at a point I’m much more confident with. I intend to have solvent tank on floor or bottom of rack in the end. I intended to put a safety cable to the handle of solvent tank if that should happen, because statistically it can, despite how careful I am. But even thinking of a safety cable for a solvent tank on milk crates, I think I haven’t done it yet because I know full well how it is fffffffffucked. Eventually I will have it all separated, rack mounted, chiller/heater. But each batch I get through the closer to that point we are. My only thing I got going for this is what makes humans strong. The ability to realize our weaknesses and conceive work arounds. I spend a lot of time using my third eye to conceive every nut bolt movement in my shop. I know it’s much less then ideal but it doesn’t leak I inspect gaskets nuts bolts Escher every time pressure test each every time. Just gotta make it work as safe and fast as possible. My partners think it’s super easy simple like turning on a light. So I have that pressure also.

Pushing through fears isn’t really a productive way to go about things. Try mitigating the relevant dangers to make your process more safe and effective. How bout you start by moving your setup away from those outlets or at the very least covering them with duct tape.

And really, can you please just assemble a $20 table

As for how to increase throughout, the best way is to shorten recovery time. Try adding a jacketed base to your collection vessel and circulating hot water.

I was just about to say that’s my intention with nothing on top of it. Once upgraded and hung, it is my intention to put cls in a vented cabinet.

I was just about to say that’s my intention with nothing on top of it. Once upgraded and hung, it is my intention to put cls in a vented cabinet.

He has one, he just needs tk use it

I don’t have it yet

10lb column is a 6x48 but would be too tall for you unless you racked your system.

There are solvent capacity formulas you can see how much solvent you need to move around and fit your collection + solvent tank to.

But 10lbs even at a 7:1, you can conclude you need to have well above 70lb capacity on those two vessels.

It would be easier to have one larger solvent tank since your only recovery one at a time anyway.

Yeah was thinking about that. Only reason considered two 25# tanks was so current solvent tank didn’t become obsolete and lessen the cost of the newer tank. Also so twin columns both got same volume. But that was thinking4:1/ 5:1 not 7:1. Personally never heard of 7:1 yet! But the ratio goes up as you increase material per run? I had to upgrade the splatter with the current jacketed spool to improve the seal of 12”clamp over second hand one I started with. It’s currently under utilized till upgrading. But twice the size of what I currently do. Only fills 1/3-1/2 with the 25# in it. It would only either be one ten or two fives.

What do you mean of set up a table? I have tables but not sure how you intend it. Once cls is all hung and only 4 or 5’ tall in a vented cabinet, not clear how a table applies?

Milk crate challenge has gotta go lol

I have a room in my house with nothing but a bail of hay with a candle on it. Just for the fine line between order and chaos. Jk. I know. I know…

Jesus f. Christ and the f is for phenomenal ![]()

God that looks like it already is jacketed…. He just isn’t using it.

It does look that way

It’s true. Under utilized till upgrade. Splatter spool I started with wasn’t flush on a mating surface so I had to replace. So I replaced it with future improvements in mind.

God if he’d use the water jacket he’d recover billion times faster…maybe he’s emptied it for storage? Removed the lines

Is that light rated for hazardous environments? Do you have injection or recovery coils? Should not need to elevate your solvent tank, just get the right length hoses. Killa should have some for the low.

rack it.

you’ll be thankful the first time your system doesn’t fall over while full of butane and become a rocket.