We have two -80c chillers. Obviously these heat up our lab quite a bit. During the winter it was fine and we were still able to hit our set points, however now that its warmer that isnt happening. Im not going to extract if the chiller isnt where I want it so im currently in a big predicament.

What are you guys doing in your labs to keep the temperature down? I might need to add another 5 ton AC but that still doesnt really help exhaust the chillers and is counter productive. Trying to get some other ideas.

Thanks guys

Locate the chiller in another room if you can. Ghetto solution is to cut a hole in the wall and stick the condenser against it so the air blows out. Obviously don’t do this in a classified environment.

3 Likes

Try to place room exhaust close to where the heat is generating on the chillers.

Put the ac in another part of the building if you still need it.

yeah. @SidViscous is on point.

the first rule of process chilling, is don’t put the chiller in the same room as the process you’re trying to chill…

that’s what “mechanical” rooms are for (on the roof or outside work too).

edit: do you have room add a wall (and a door)? if so, explicitly ventilate the hell out of the new room thus created.

7 Likes

My solution was to have the chiller in a separate room and then just get some stainless steel tubing and connections and pipe it through the wall into the extraction room. Our fire inspector is ok with that process to keep the controlled room C1D2 so long as we seal it with fire caulk or some other kind of sealant that is allowable by their standards. YMMV.

4 Likes

My chillers are outside my C1D1 room, its not in the same room. However they are putting off enough heat that the intake for my C1D1 is pulling in this heat.

So basically I need to put the chillers in a their own room ? Build a dry wall room around the chillers with a big exhaust fan behind them?

Thanks for all the replies so far !

2 Likes

Their own space with exhaust would be ideal.

1 Like

It sounds like you have a few options.

-

You could change the source of air intake for your C1D1 room so it’s not pulling from the warm room already containing the chillers.

-

You could leave everything as is, add an exhaust blower to vent the air from the chiller room out to the external atmosphere.

-

You could move the chillers to their own separate room with their own separate exhaust.

All of the options obviously have their own pros and cons and costs associated with them. It really depends on what situation works best for you!

3 Likes

If they’re not in the C1D1 just use fans to outdoors. An economizer is the correct thing to use but a roof fan on one side of the chillers and a wall fan on the other with one blowing in and the other out will work just as well if not better.

Also: obviously make sure the “in” fan is nowhere near your C1D1 exhaust.

1 Like

Just make sure if you build a room for them with a big exhaust fan you will need just as much air coming into the room, so size the intake accordingly.

4 Likes

Ok, not quite in the same room, but your HVAC guy fixed that for you…#^%<!^

Moving that intake may be the easiest solution…

Solid point. Last thing one needs is the “chiller” room sucking in make up air from the C1D1 space next door because it’s under negative pressure (slight positive pressure would be ideal).

3 Likes

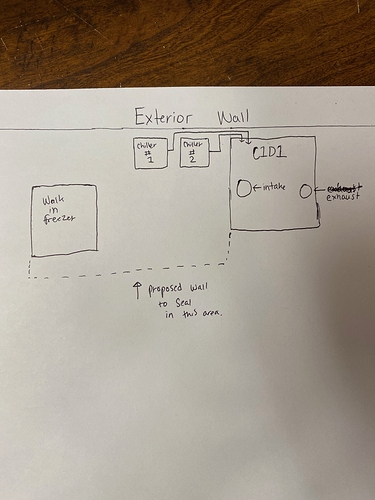

Yes we have room to add a wall with a door. The only issue there is the new room will also incase one side of my C1D1 which has the intake fan. I could run a AC duct to the intake fans for the C1D1.

The area with the chillers also has a walk in freezer so thats generating heat as well. These are all of the left hand side of my C1D1 room. The two options I have would be to incase that whole area with dry wall and a door, put in a air return and then exhaust the back of the chillers out of the building. Other option would be to just build an inclosure around the chillers them selves with a air return and exhaust going outside. Which of these sound more ideal? The money is not an issue , this down time is killing our production.

if you’ve also got a freezer in there, dealing with that at the same time as the heat generated by the chillers would seem ideal.

figuring out the best solution from here is non-trivial. presumably a qualified HVAC tech could advise on your options. you might want to use someone other than the guys that set up your current system…assuming they were given correct usage data upfront last time.

3 Likes

I would strongly advise to keep the room as big as possible and provide air to the freezer as well. 2 birds 1 stone.

3 Likes

HI,

yeah, you want to have these in an adjacent room with some good air exchange.Pass the hoses through the wall to your process.Doing this also keeps keif off your expensive equipment.

2 Likes

Make sure you insulate the bulkheads in the wall or feed your chiller and heater hoses at different points.

I’ve seen the glycol lines from the chiller freeze the water lines from the heater times too many times.

3 Likes

Can you post a picture of its current install location?

1 Like

Yeah here is something I just drew up .

After all your suggestions im thinking of framing in that area with drywall and a double door. Than putting something like this (Continental Dynamics® Direct Drive 30" Exhaust Fan w/ Shutter, 1 Speed, 8000CFM, 1/4 HP, 1Phase) behind the chillers exhausting outside. Thoughts?

I would also have an air exchange hole on the exterior wall near the freezer

1 Like

What are your year round ambient temperatures? What’s on the other side of that external wall?

Pulling in make up air from a asphalt parking lot in midsummer vs a snow drift in winter will certainly change how your chillers work…

3 Likes

20-30f in winter, 70-85f in summer. The other side of the exterior wall is a gravel parking lot.