Wait what if I wanted to cut out using dry ice for recovery and extraction. I would just switch to a jacketed stainless tank and a fully jacketed column and use ln2 right?

Lc02 would work better. Ln2 would be a bit too cold I think. It might work for recovery, but I haven’t done any research on it. I think lc02 is a way to go. Fully jacketed and coiled 50lb tanks for lc02 from bizzy are around 5k or less, I think. And that tank could handle recovery for you and you wouldn’t need a coil at all. Just go straight to the tank with the vapors after the sieve.

His big doubled jacketed is 10k. The other one is 6500.

Nboler has a jacketed tank, too. But I don’t know his price or lead time. I believe he’s 12 weeks out right now

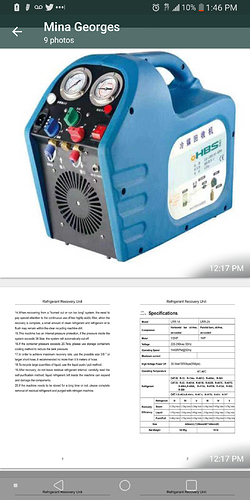

https://www.bestvaluevacs.com/mastercool-spark-free-combustible-gas-recovery-machine.html

Would it work for recovery?

That’s a hard “meh”. Your neighbors are going to ask what you’ve been building with the loud ass air compressor.

Fack!

You use a chiller, no? Why go that route if you could just use LCo2

100% agree. My current setup was already here and I had to make due with what was here.

Hey just a quick question, do you need to empty your tank prior to recovery? say I use a 1lb CLS, but I have a 20lb tank and am going for a 10:1 solution to material. Is it safe or even possible to recover with a half full tank?

So just an idea, but what are the recovery pumps offered that don’t contaminate the end product of risk explosion?

This system I’m cl s with crc system is a bit to heavy for me(due to disabled shoulder)

My other option would be using lifting system and stay passive.

Any recommendations with pictures?

Nope mvps suck. Passive is scalable but you still need to vac down material so unless you like blowing off gas or waiting forever active is required

Active is never required. You can run heated ricurculated baths and chillers on your setup to dial in your recovery. if you do it right you can pull a # a min.

Lol if i had to wait at the rate of 1#/min…if you want to process more and faster you will need active to at least vac down your material vessels. 1#/min:joy:![]()

![]()

![]()

![]()

![]()

![]()

![]()

My recovery pump let’s me know when my vac depth gets low. I feel like I’d be doing weekly rebuilds if I used it to vac down vessels

Youre right it wears valves out faster but with bigger gas compressors those are just drop in parts costing a few dollars. Part of a monthly service interval. Active isnt required unless you wanna do more and faster.

You don’t need to have a recovery pump to pull remaining solvent out of the material. If you have a jacketed column, you can just recover the remaining vapors with ease. And 1lb a min is easy to get. Passive systems are achieving 5-6lbs a min now.

My point is it is way too slow at scale to recover tiny amounts left in material by depending on solely a heat transfer surface not entirely in contact with all biomass. Vacuum speeds this process greatly. Recovery by dT of the extracted concentrate can be scaled well beyond single digit lbs solvent recovered effectively but youre held back if you wish to do the same with extracted bio.

Again not entirely true.

Ok. You make an assertion. That assertion is that you can pull residual solvents from spent biomass inside the system as quickly with dt as you can with dP and dT. Is that what you are saying? Please explain if so.