Not sure if you have a local swagelok location but they offer a super helpful training class on tube cutting, proper swaging, tube bending math and bending using their brand name tube bending tool. I took it a million years ago - basically you add the wall thickness x2 to each bend to get the desired length before the bend (idk if I’m explaining this clearly but if you take the class it’s clearer)

If it were me, and my company was super interested in squeaky clean audits (even though it would only be a reason for apeks to not service the unit), I’d just shell out the $1k since after buying tube, the two swagelok sets and a tubing cutter, you’re already almost half way to two thirds to $1k already.

But if you like tools and zero downtime in production, I’d buy the tube bender and cutter set, take the class on how to not destroy swageloks because they are easy to fuck up and I have fucked them up in the past not knowing the hand tight plus a quarter turn and marking the nuts, and just do a small segment using 2x swagelok sets as hinted to above. Then atleast you’ll be producing while you’re waiting for the lid or you can just say screw the lid.

Additionally I’d grab some of the common swagelok or similar brand stuff around your lab, not a ton because it’s expensive af, but the ones that would impact production time if they happened to be sold out in the future.

8 Likes

BRUH

Literally cut the tube and replace with a new nut and ferrule set–$2.00 fix.

3 Likes

This was discussed.

Not my name on the license or the insurance.

It will be done on the one in the pic for a spare. But the guage has to be fiddled with due to length of tube. Needs an elbow or 2.

Also more than 2 bucks

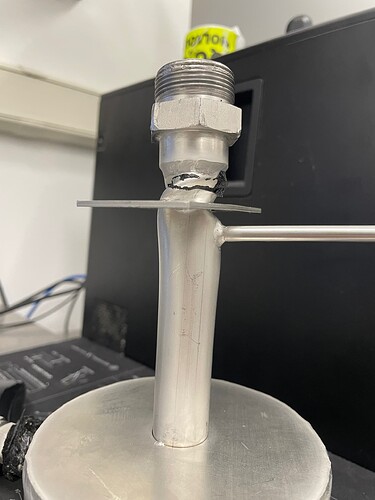

Here’s a cross threading nightmare (@chempistry remember that one time…):

I cross threaded the M30x1.5 fitting on a Huber 905…

That particular connection is connected to the pump housing and so I had to remove all of the vapor sealed huber guts, along with insulation, go through the absolute nightmare of removing the housing and cut out/replace the in line thermocouple.

Then we had to find a welder to fix it. I went to a badass machine shop that does tons of stainless and he says “it’s too thin, nobody thinks they can weld it to be safe”

One of our managers had a buddy who did tig welding in his spare time, so he fixed it.

If there’s a will, there’s a way when it comes to fixing things.

Edit: Here’s the after

7 Likes

Glad you got it fixed. What a nightmare

1 Like

That’s just branded which is why it’s that price. Literally, you can use any pipe cutter that can cut steel and a regular every day deburr tool that a plumber uses. The only thing you’ll need to buy that is actually swage, is the connector you have to replace. It looks like you just have to take the other connections (gauge, prv, etc) off the lid to replace that fitting and you’ll be fine.

I know you’re also buying a new lid and not worried about this one. But, it is an extremely easy fix. If you guys had a plumber there laying some pipe he has the tools already on him.

And when you put the new fitting on slide the hard line into whatever you’re connecting to, so the hardline bottoms out into the connector then tighten the new fitting. When it becomes finger tight, tighten one and a ¼ rotations and you should be good.

9 Likes

Thank you for the very helpful info.

I saw a few other pipe cutters for much cheaper.

Is there a good off brand pre swage tool?

I use hilmor, no issues for years of daily usage (hvac)

1 Like

There was a YorLok store in LA. Never used though.

They are filtering winterized CO2 crude with the Nutsche to remove fats before solvent recovery. I worked with their management team during their lab buildout.

1 Like

Thank you for the explanation that makes sense.

Very fancy way to winterize!

@LunaTechnologies do you guys provide install and PE and service for used equipment

Is this @johnbigoilco luna that @Cannachem was selling?

It looks to be one of the much earlier lunas, older valves, older style solvent tanks, and the horizontal mol sieves.

could be

only see the one on the intertubes

What improvements have been made since the gen 1.0 that I used?

I dont know all the specifics on those changes as i never had my hands on an older model for more than an hour or two. This unit for sale just looks like a very early model, the three things i shared above are the main difference i can see.

Yeah I had all those features you mentioned on my antique

valves matter considerbaly

@Extractionperson2.0 After reviewing this topic with our team over the past week we have decided that we will try to offer support for any Luna Tech system, old or new. Just reach out to us directly in so we can understand the circumstance and we will communicate what service we would be able to provide.

1 Like

This is not the machine based on the plate on the collection or distil pot as they call it. Also our valves were red not black. @thesk8nmidget

3 Likes