Hey gang!

I thought this would be a good place to document a new lab I have been building out as a part of my new job In Michigan.

My fault for taking the last thread off the rails so let’s keep this one on track.

Hallway floors were done last week. I like the color

11 Likes

I decided to keep wet floors with some grit on them for safety so I tried to match a solid color to one of the colors of the flake in the epoxy

What do you think?

7 Likes

Time to make the terpenes

3 Likes

So what’s the plan ?

Extract the terps of biomass with ? Propane ?

How much solvent are you thinking of using ?

Cleanup after extraction of straight HTE

Nice gear !

4 Likes

I’m going to make a lot of distillate

All of the material is pretty good

So instead of losing the terps to the ethanol when I dewax I’m going to pull them off the better biomass with this lil 5l apeks

Can do 3 lbs in about 30-45 min

It was already purchased I wouldn’t buy a co2 machine. I would put hte in a spd to pull terps or like raw garden just mix hte with disty for the easiest way to make a good cart

2 Likes

What state is all this in?

1 Like

Definitely money to be made there

3 Likes

Retails in 5 states working on 3 more and I’m building processing and cultivation for each

4 Likes

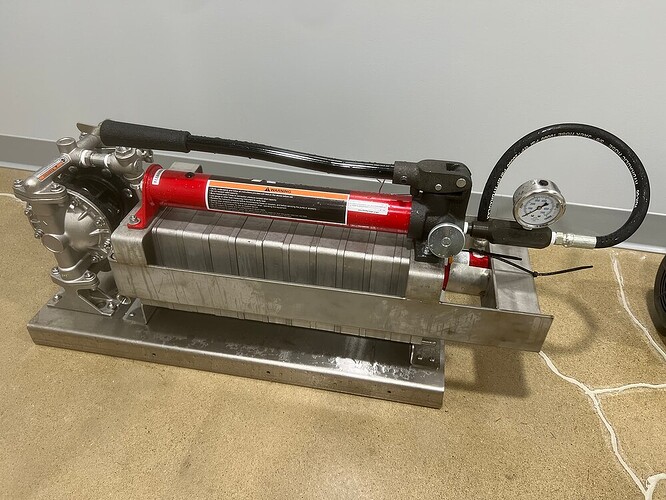

Pig filter from Summit

That stainless table that comes with it was a labor intensive assembly YMMV

Pairing this with your standard type of reciprocating air compressor to save 10-15k over a screw compressor with air dryer

2 Likes

60 gallons should work, may go bigger JIC

1 Like

Make sure you get an air drier for the air compressor. Filtering cold ethanol w an air operated diaphragm pump the ethanol can freeze all the moisture coming thru in the compressed air and you’ll have a bad time…

$0.02

Edit: For what it’s worth, a reciprocating air compressor makes pretty dirty air (oil, dust, water, dust from corrosion of tank internals—for consumable products or pharmaceuticals you really wanna go for a scroll compressor, but with adequate drying and filtration it shouldn’t be too bad.

18 Likes

You’ll likely want a refrigerated air dryer.

Desiccant beads will need almost daily changes, like molesieves.

https://www.harborfreight.com/compressed-air-dryer-40211.html

4 Likes

I’ll second or third the air dryers, and add that an air lubricator with Low BP lubricant helps if your dryer fails and you need to keep processing while dealing with it. Ethanol will work too, if you vent the exhaust to a safe area.

3 Likes

Your intended method is how raw garden does it. All their coas are 60-80% thca. Def not disty

3 Likes

I was gonna go Vulcan or black hawk with an air drier and return this if it wasn’t doing what I wanted

Thanks for the drier and filter tip. These are not ideal but I was goi g to see why o could do with it for limited startup use.

2 Likes

Compressor world has some great prices. I went with a Quincy dryer for my air system they have a great reputation and easy to use reliable system.

4 Likes

Anyone ever purchased from Mach here?

They got sales

1 Like

I want a butane centrifuge.

I think that’s the next step

A centrifuge that passes

Nitrogen sweep for terps

Butane/propane for residual terps and noids

Ethanol for residual noids

If the biomass is being agitated in a bath of solvent compared to having solvent passed over I could see run times being decreased.

Pass the butane and ethanol tincture several times through new biomass until saturation level is reached which could be detected by light

2 Likes

Heptane for second wash. Duh

2 Likes