What is the sample depth for your autosampler? This is the depth the needle on the autosampler will go into the vial. It should be 0mm as a default but maybe it is changed on your machine. May explain why you are getting peaks on manual injection but not auto.

Well, more strangeness has occurred. It looks like the seal on the swaglok for the detector side was eaten away and is leaking, best guess right now samples are probably not making it to the detector… more updates soonish

Your machine is cursed lol. Stopping messing with the ghosts

I’m not sure what your method is but I have a few comments:

Slowing your flow rate will help separation.

That general upward trend indicates some column bleed (as far as ive been told) what temperature are you starting your analysis at? What is the temp ramp rate? How long are you holding at that temp?

It seems like your carrier gas pressure must also be low. Are you sure that peak near 3mins is your solvent peak? Like did you check your spectra?

Also, with the method being that short it seems you’ll never fully clear your column and so you’ll never reestablish baseline.

Did you bake out the mass spec chamber?

Anywho, just some thoughts

Nah, just the idiot touching the damned thing…

So in my absentmindedness while trying to put the capillary adapter and swaglok nut back on, I installed it in the wrong direction (gee no wonder its leaking still…). Not entirely sure yet if I can separate the adapter from the ferrule just yet. Ordered a replacement off ebay just in case…

Leaking at the detector is the only thing left that makes any sense. Manual vs auto injection doesn’t seem to matter, sometimes it gets to the detector, sometimes it doesn’t.

I’m really hoping getting this ferrule and adapter sorted is the last piece to this thing running smoothly. I may re-install the used column and put this relatively brand new one back in storage for now, but also maybe not

I’m not sure, I’m not sure its configurable either. At this point I think its not the injections, but likely the detector and a leak. System is shutdown for now. Maybe tomorrow, maybe by end of week ![]()

One day I’ll recoup my investment…

Son of a bitch

The needles aren’t long enough…

Swapped back to the old bent ass needle thats about an inch longer and voila…

Or so I thought. Thinking more about why the needle length may be affecting things, I determined it was likely the material to be analyzed simply wasn’t getting to the column or detector.

I think there’s a few things that caused issues. I suspect when I used a wrench to remove the inlet seal it also slightly loosened the larger retaining nut. This caused hydrogen leaks at the inlet side in the oven.

I performed the following maintenance items:

- replaced septa

- replaced liner

- re-installed, and re-cut the column (using new column currently)

- 4-6mm approximately above the ferrule on the injector side

- 68mm approximately above the ferrule detector side. I believe this was an issue originally, as it was previously set to 48mm

- adjusted gas lines and moved around detectors, currently using detector B and injector A

- replaced the nut and ferrule for 1/8 column adapter on detector side

Couple things, currently setting hydrogen pressure to meet 40ml/min flow rate at the FID block, however this pushes the split vent to no less than 65ml/min. This effectively is a 26:1 split flow. I don’t know that I can get this to 50 without an additional regulator (to separate the FID block and the split vent flow)

Inserting the column into the FID through the capillary jet and adapter is less smooth than one might think it should be. I am unable to get the column to install without hitting something on the way in. Not sure what effect this may have on things.

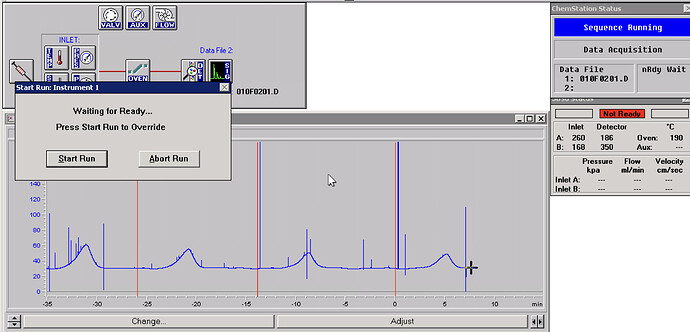

Currently running some back to back samples on the auto sampler (same source), getting solvent peaks and some artifacts. I guess we’ll see if running the method repeatedly clears it all up.

On the plus side, it looks like we’re back in business, just need those damn 250ul inserts so i can have the auto sampler run the injections (probably should avoid manually injecting from here on out where possible for the sake of consistency)

good on you! using a VM on instrumentation like this really is the right solution. remember to take regular snapshots and backups.

Sometimes my old life bleeds into this one… ![]()